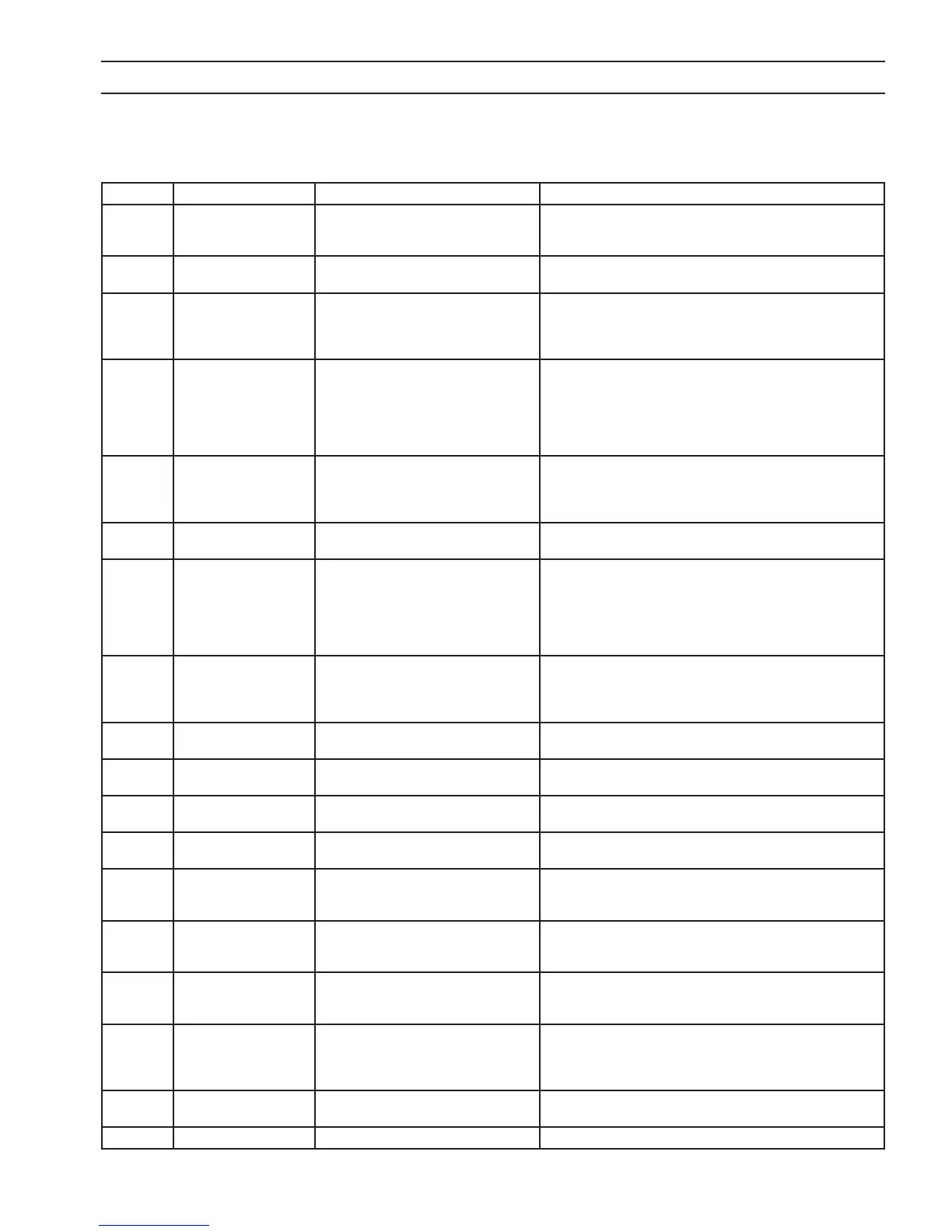

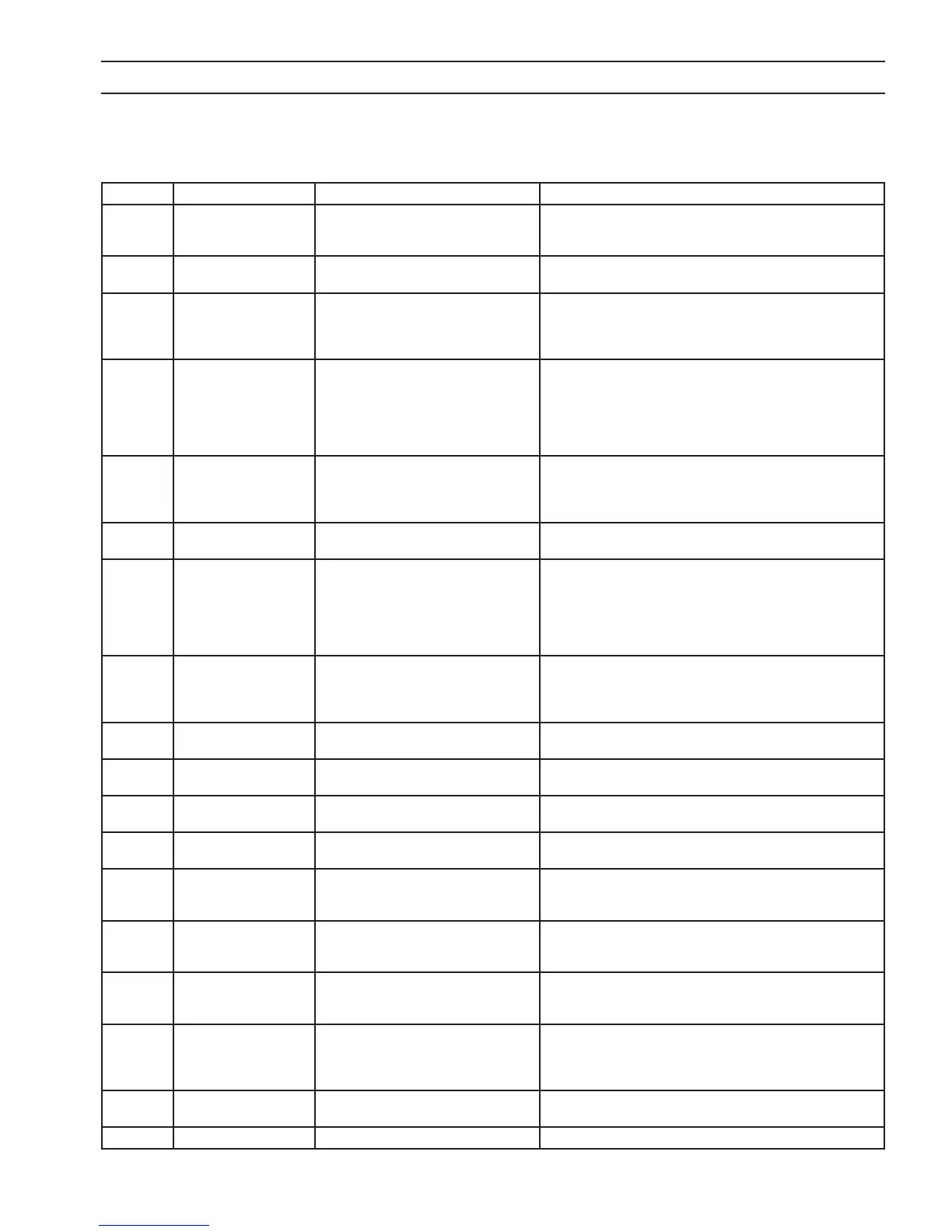

43

SECTION 6 TROUBLESHOOTING

17 IGBT DRIVER ERROR IGBT driver board error.

18 CUT/MARK VOLTAGE

TOO LOW

Output voltage fell below 70 volts dur-

ing cutting or below 40 volts during

marking.

During cutting/marking, the output voltage dropped below

threshold limits. Check for short in the torch cable or torch colli-

sion into plate or short between electrode and nozzle.

19 SLAVE P/S NOT DE-

TECTED

Master requested to engage slave power

supply but slave is not present.

Control board (PCB1) is looking for slave power supply and can-

not locate one.

20 SHORTED IGBT Output voltage detected before start

signal issued or PWM engaged.

Output voltage detected during start-up of power source before

start signal or PWM signal issued. This could be due to bad IGBTs

or driver board. Check the IGBTs and gate pulse connections on

the driver board.

21 MAIN CONTACTOR

FAULT

Main contactor failed to engage or

disengage.

After bus is pre-charged to the threshold limit, bus charger

contactor (K2) disengages and main contactor (K1) engages to

charge the bus to it’s full potential failed to do so or disengages

to shutdown the bus after 5 mins of idle condition will result

in this error. Check for faulty input fuses, main contactor (K1)

contacts failure, and main contactor relay (RB1-2).

22 CURRENT SENSOR

ERROR

Work current is greater than Electrode

current plus threshold limit.

Work (HS2) current is greater than Electrode (HS1) current above

the allowed threshold. This could be due to bad sensor. Check

the hall sensors and their connection to the control board

(PCB1).

23 PS ENABLE ERROR Power Supply Enable signal is interrupt-

ed, please check the E-STOP circuit.

The power supply signal that enables the power source is inter-

rupted. Check the CNC/Process controller E-STOP chain.

24 SPI COMMUNICATION

FAILURE

SPI communication is lost between Main

and Servo micro. Restart the machine

if still doesn’t clear, replace the control

board.

The main micro (U19) and servo micro (U17) on the control

board (PCB1) communicate via SPI protocol, if any data failed

to transfer between the micros this error is active. This error

requires the reset of power to the power supply. If the error isn’t

cleared after the reset of power then contact ESAB’s service

department.

25 EEPROM FAILURE EEPROM Failed, replace Control Board. When writing or reading operation failed between main micro

(U19) and EEPROM (U16), this error is active. Please recycle

the power to the power source, if still doesn’t get cleared then

contact ESAB’s service department.

26 SLAVE POWER SUPPLY

FAULT

Error detected in slave power supply

30 SERVO FAULT Servo has fault. Servo has detected the current above the requested current,

check hall sensors and restart the plasma unit.

31 LOW COOLANT FLOW

ERROR

Coolant ow is too low to start the

process.

Coolant ow rate is less than 0.3 GPM, please check for the leaks,

faulty sensor.

32 HIGH COOLANT FLOW

ERROR

Coolant ow is very high. Coolant ow rate is greater than 2.5 GPM, please check for the

faulty sensor, coolant connections.

33 WATCHDOG ERROR CAN Communication error CAN communication between power source and CNC/Process

Controller is lost. Check for the CAN cable connection, faulty

cable.

34 IGNITION/ARC LOST Ignition/Arc lost in dwell state immedi-

ately after it red once.

After the arc is established, it lost before stabilizing in the

DWELL state. Check the consumables, gas ows, height be-

tween torch and plate.

35 NO DRIVER BOARD Driver board connection lost or driver

board fault.

If the connection between Driver board (PCB2) and Control

board (PCB1) is lost, this error is active. Check the ribbon cable

connections between J12 or J13 on PCB1 and J2 on PCB2.

36 HIGH ARC VOLTAGE or

LOW CUT CURRENT

Arc lost during cutting due to increase in

arc voltage or decrease in current.

If the height control is blocked or not working there could be a

possibility of losing the arc due to increase in arc voltage or de-

crease in the current. Please check the level of the plate, height

control connections, part program speed.

37 CNC START SIGNAL

ERROR

Start signal is still present after the cut is

nished or error interrupted the process.

Please check the communication cable or start signal relay on

the CNC.

38 COOLANT LEVEL ERROR Coolant level is below threshold. Please make sure there is enough coolant in the tank.

6.2 Help Codes cont’d

Loading...

Loading...