44

SECTION 6 TROUBLESHOOTING

6.3 Fault Isolation

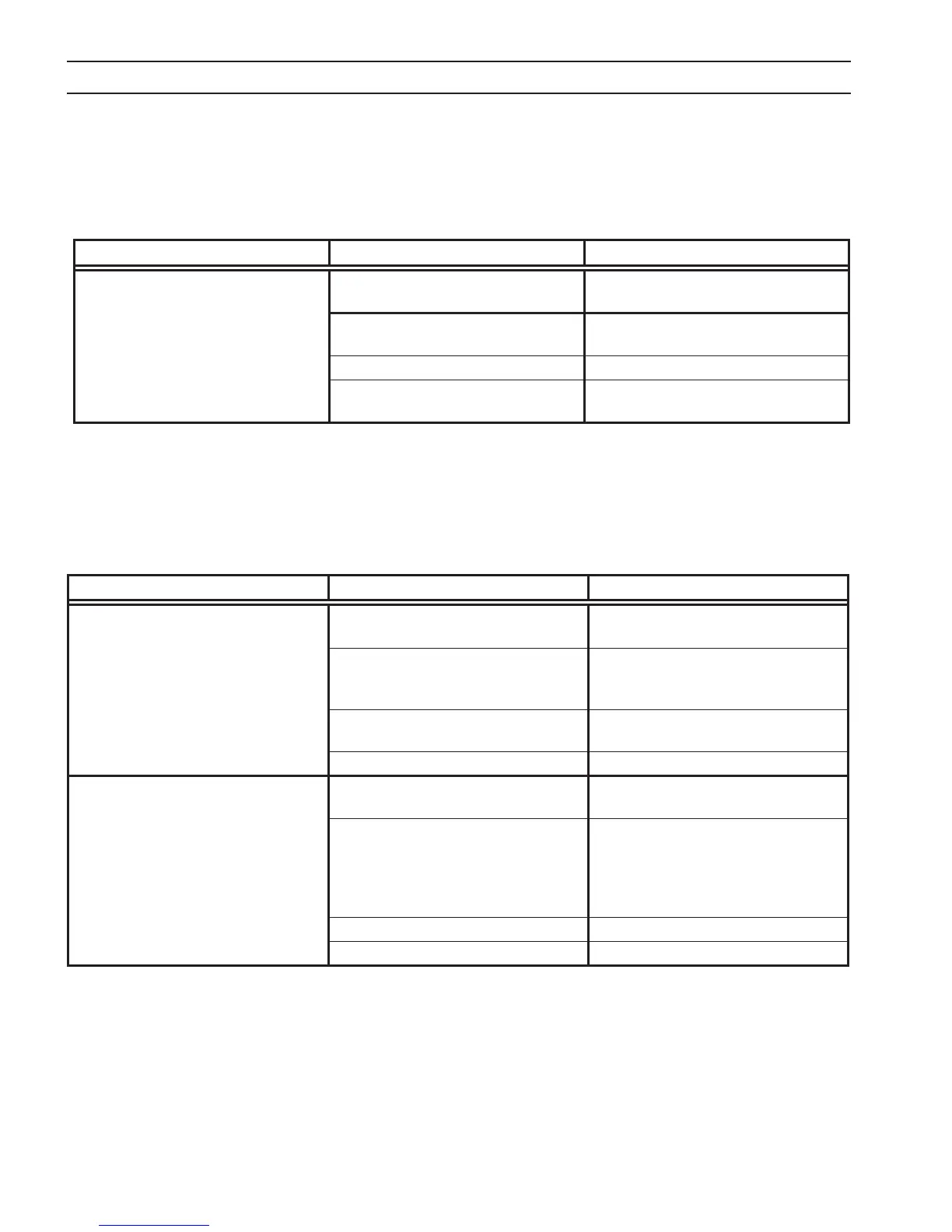

6.3.1 Fan Not Working

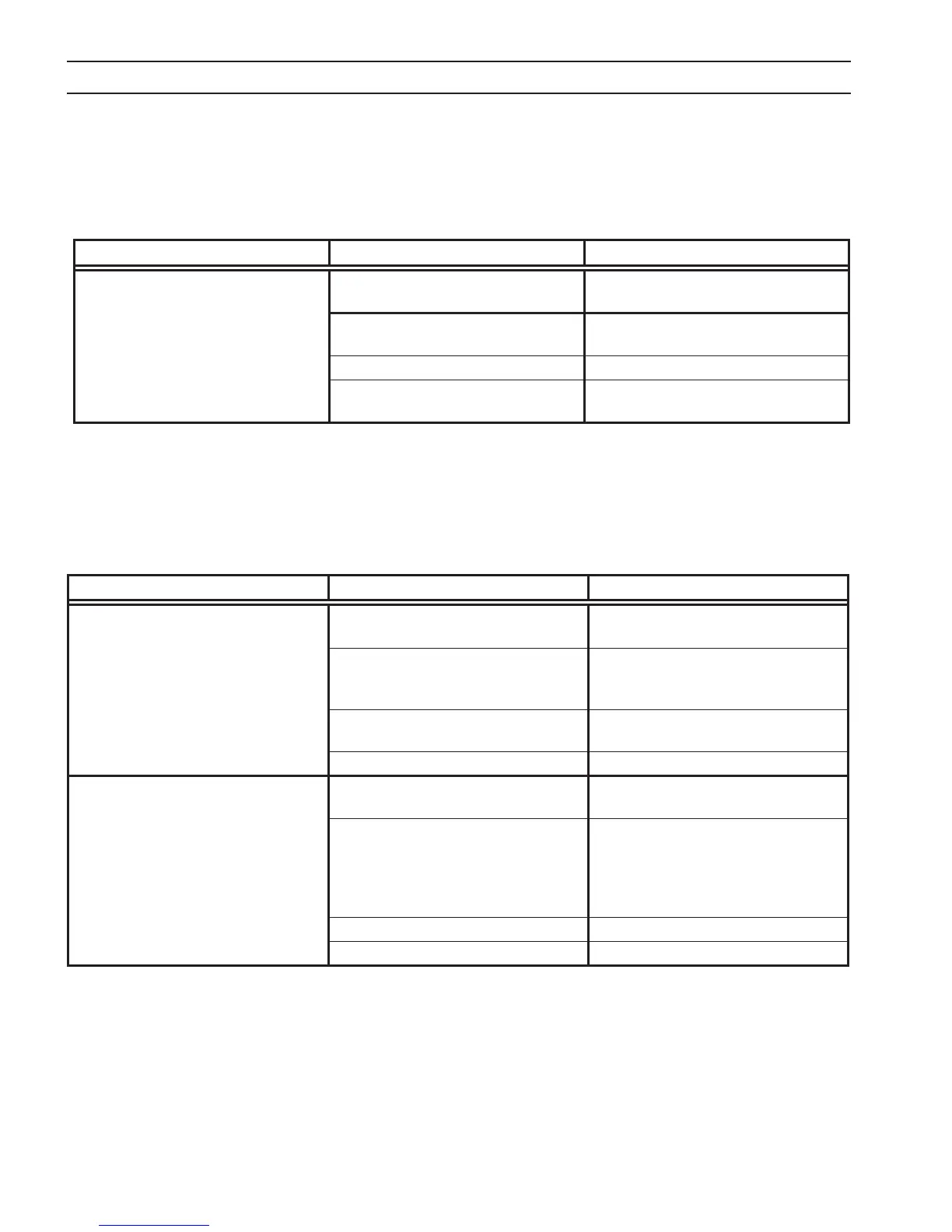

6.3.2 Torch Will Not Fire

Problem Possible Cause Action

Main Arc Transfers to the work with

a short “pop”, placing only a small

dimple in the workpiece.

Communication between plasma unit

and CNC or process controller is lost.

Check communication cable.

CNC or Process Controller removes

the start signal when the main arc

transfers to the work.

Make sure CNC or Process Controller is

sending start signal correctly.

Remote current values are not pres-

ent.

Check if correct current values are

sent down the CAN Bus.

Current value is too low. Increase current value.

Arc does not start. There is no arc at

the torch. Open circuit voltage is OK.

Open connection between the power

source positive output and the work.

Repair connection.

Pilot current and/or start current

should be increased for better starts

when using consumables for 100A or

higher (Refer to process data includ-

ed in torch manuals).

Increase pilot current. (Refer to pro-

cess data included in torch manuals).

Fault light is ON. Check Help Codes table.

Faulty PCB1 (control board). Replace PCB1 (control board).

Problem Possible Cause Action

Fan does not turn ON

This is normal when unit is in idle

mode for more than 5 minutes.

None

Broken or disconnected wire in fan

motor circuit.

Repair wire.

Faulty fan(s) Replace fans

Relay failed to close

Check relay connection and/or replace

relay.

Loading...

Loading...