46

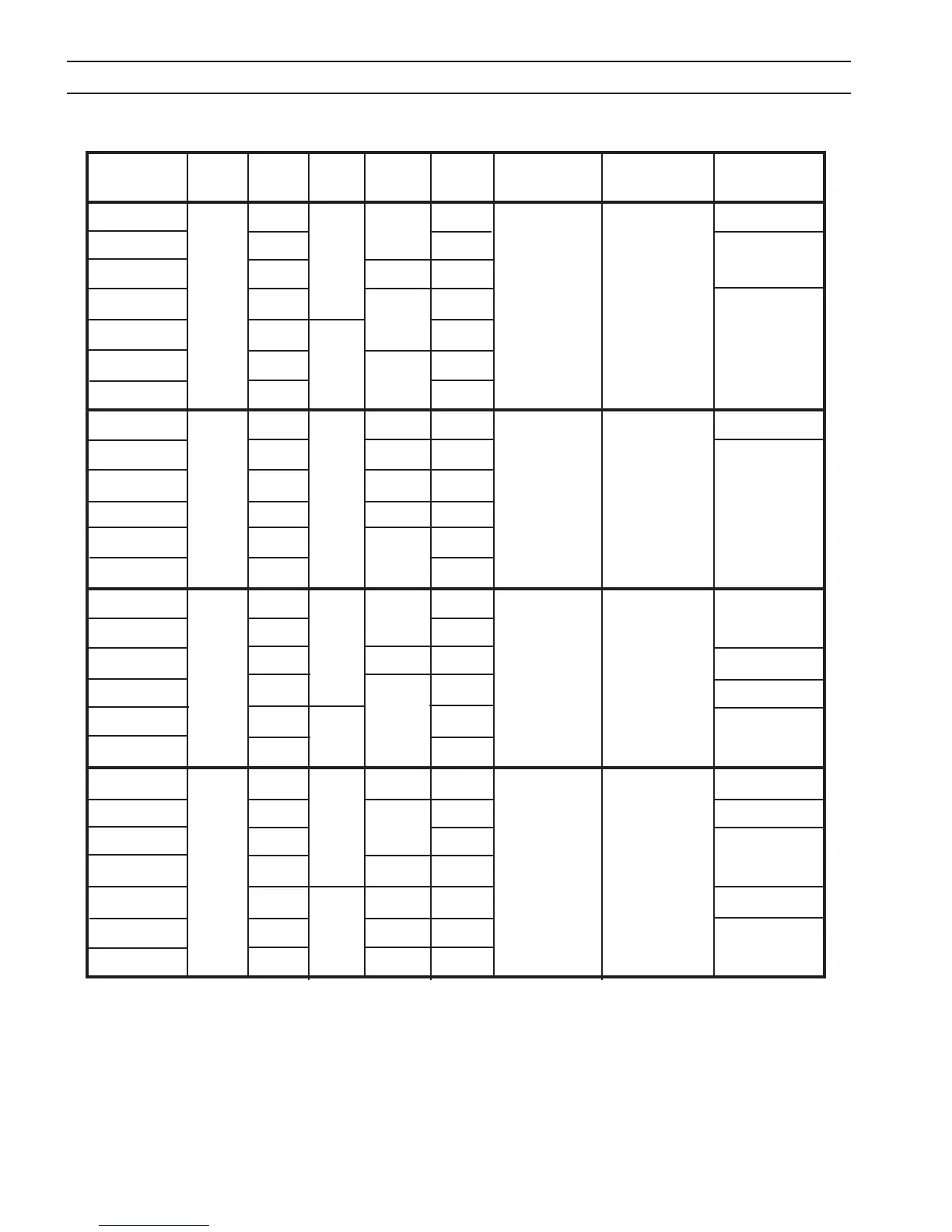

CS - 3/16 (4.8) 150 160 (4.1) 3/8 (9.6) 1/8 (3.2) 143 Air - 25 (1.7) Air - 50 (3.45) Air - 85 (5.86)

CS - 1/4 (6.4) 140 (3.6) 145 Air - 55 (3.8)

CS - 3/8 (9.6) 90 (2.3) 3/16 (4.8) 156

CS - 1/2 (12.7) 75 (1.9) 1/4 (6.4) 160 Air - 65 (4.48)

CS - 5/8 (15.8) 50 (1.3) 1/2 (12.7) 164

CS - 3/4 (19) 45 1.1) 3/8 (9.6) 179

CS - 1 (25.4) 25 (.64) 184

SS - 3/16 (4.8) 150 200 3/8 (9.6) 1/8 (3.2) 138 Air - 25 (1.7) Air - 50 (3.45) Air - 85 (5.86)

SS - 1/4 (6.4) 165 3/16 (4.8) 146 Air - 65 (4.48)

SS - 3/8 (9.6) 95 1/4 (6.4) 155

SS - 1/2 (12.7) 60 5/16 (8) 163

SS - 3/4 (19) 25 1/2 (12.7) 3/8 (9.6) 175

SS - 1 (25.4) 15 185

AL - 3/16 (4.8) 150 200 (5.1) 3/8 (9.6) 3/16 (4.8) 148 Air - 25 (1.7) Air - 45 (3.1) Air - 85 (5.86)

AL - 1/4 (6.4) 140 (3.6) 149

AL - 3/8 (9.6) 105 (2.7) 1/4 (6.4) 159 Air - 65 (4.48)

AL - 1/2 (12.7) 80 (2) 5/16 (8) 174 Air - 85 (5.86)

AL - 3/4 (19) 45 (1.1) 1/2 (12.7) 180 Air - 65 (4.48)

AL - 1 (25.4) 30 (.76) 184

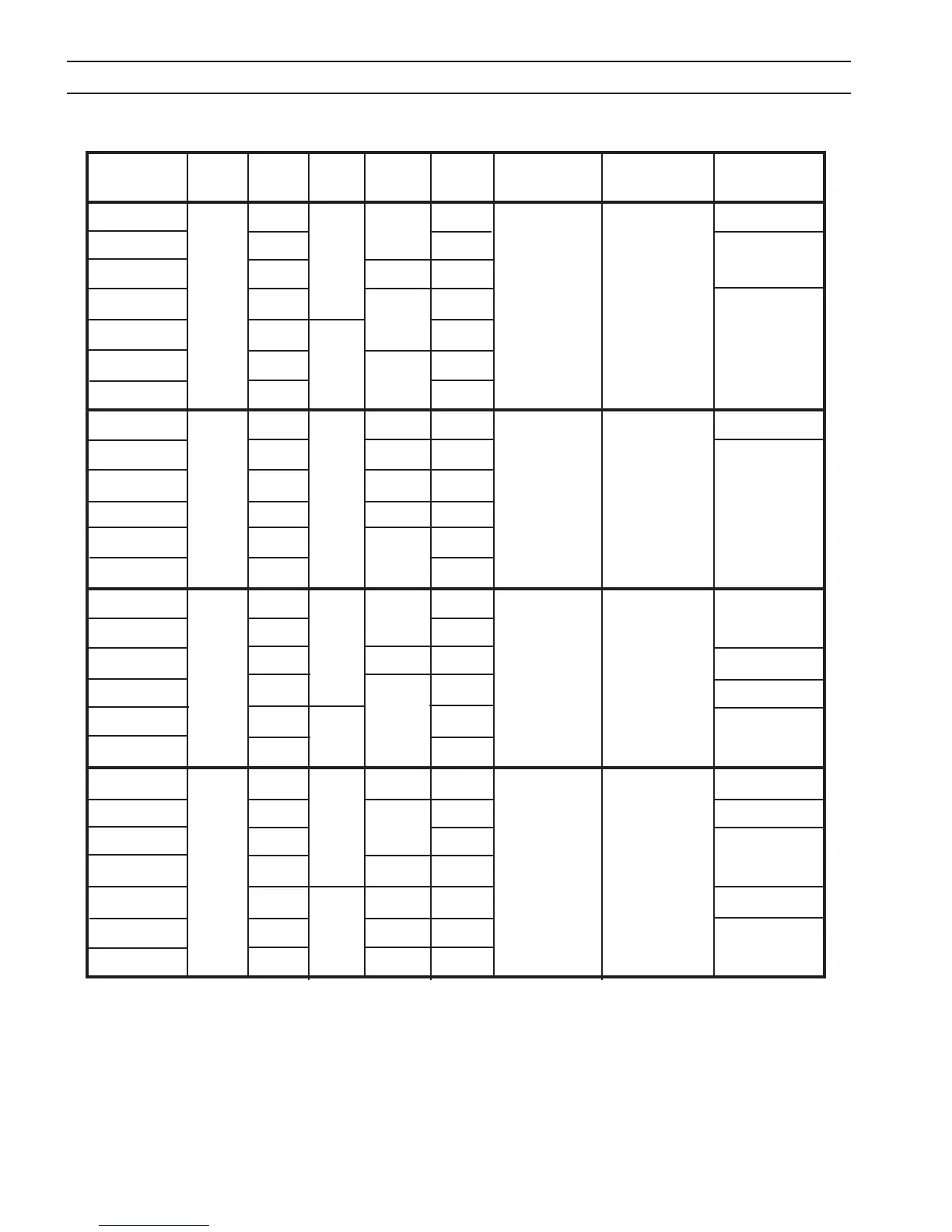

CS - 3/16 (4.8) 150 160 (4.1) 3/8 (9.6) 1/8 (3.2) 127 N

2

- 25 (1.7) O

2

- 45 (3.1) Air

- 85 (5.86)

CS - 1/4 (6.4) 150 (3.8) 3/16 (4.8) 130 Air - 45 (3.1)

CS - 3/8 (9.6) 90 (2.3) 134 Air

- 65 (4.48)

CS - 1/2 (12.7) 75 (1.9) 1/4 (6.4) 142

CS - 5/8 (15.8) 55 (1.4) 1/2 (12.7) 5/16 (8) 151 Air

- 85 (5.86)

CS - 3/4 (19) 45 (1.1) 3/8 (9.6) 157 Air - 65 (4.48)

CS - 1 (25.4) 25 (.64) 5/16 (8) 160

SECTION 4 OPERATION

4.4.3.4 Process Data at 150 Amps (PT-19XLS and PT-600)

Current

(Amps)

Pierce

Height

in.(mm)

Cutting

Height

in.(mm)

Arc

Voltage

(Volts)

Travel

Speed

ipm(M/m)

Material

Type-Thickness

in. (mm)

Start Gas

Type/Pressure

psi(bar)

Shield Gas

Type/Pressure

psi(bar)

Plasma Gas

Type/Pressure

psi(bar)

NOTES: When using a 50 ft torch, a dwell of approx. 3 sec. is required to allow the N

2

start gas to be purged out by the O

2

cut gas.

CS - Carbon Steel, SS - Stainless Steel, AL - Aluminum

All Air Plasma/Air Shield, 100 Amp cuts on Aluminum have good surfaces except 3/4” (19mm) AL that has poor surface.

All Air Plasma/Air Shield, 100 Amp cuts on Stainless Steel have fair surface except 3/4” (19mm) SS that is very rough.

All N

2

Plasma/N

2

Shield, 100 Amp cuts on Stainless Steel have fairly good surfaces except 3/4” (19mm) SS that is fair.

Pilot Arc -- HIGH

Loading...

Loading...