7 TROUBLESHOOTING

0446 455 001

- 25 -

© ESAB AB 2021

7 TROUBLESHOOTING

Perform these checks and inspections before sending for an authorised service technician.

The following table describes the welder error code, as well as the causes and solutions

Error

Code

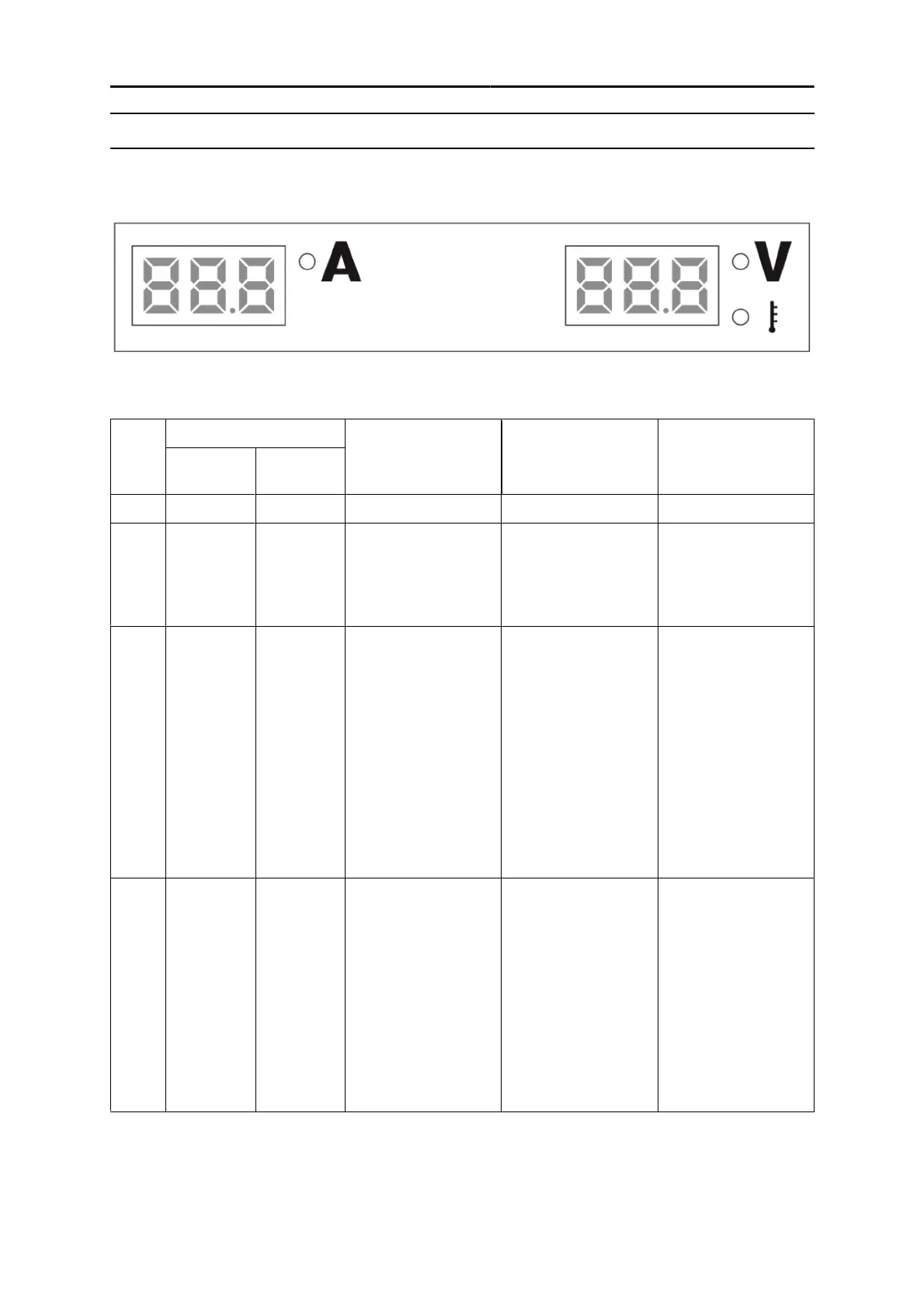

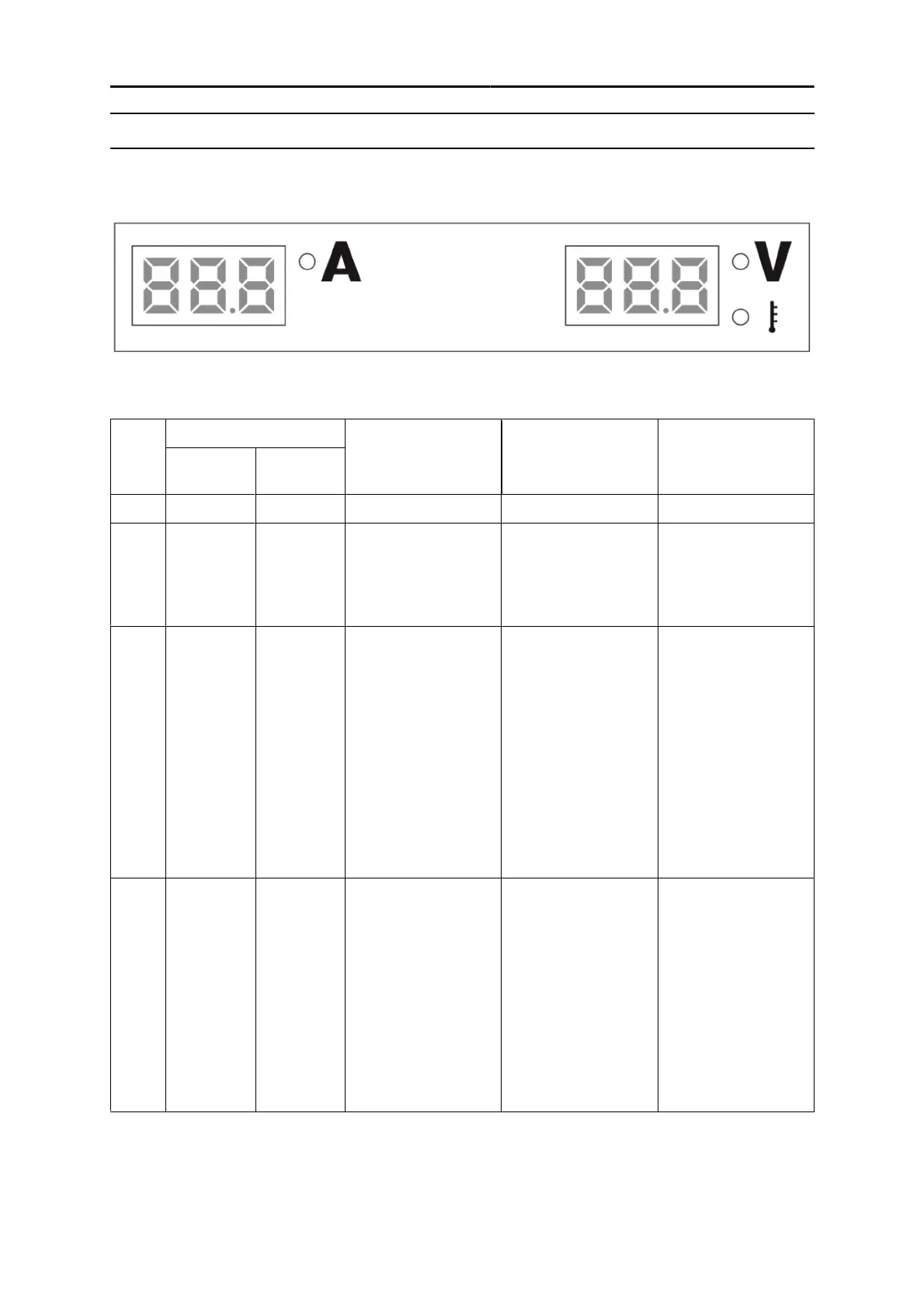

Displayed Content

Fault Cause Solution

Left

display

Right

display

F00 F00 None Power-on self-test

E1 E1 None Welding torch fault When the equipment

is turned on, the

welding torch trigger

switch is on. the

switch may be faulty.

Turn off the switch.

Replace the welding

torch.

E2 E2 None Output terminal

over-temperature

The OKC terminal

and welding cable is

not connected

properly. The copper

cross-sectional area

of the output power

cable is too small.

The output cable

OKC fails to meet

the specification

requirement. The fan

does not work or

slows down.

Verify the OKC

terminal and welding

cable is connected

properly. Use cables

with correct

cross-sectional

areas. Select

suitable cable OKC.

Verify that the fan

blades are not stuck

with any foreign

objects.

E3 E3 None Abnormal input

power

The input power

cable is not

connected properly.

Input power

overvoltage occurs.

Input power under

voltage occurs. Input

power phase

imbalance occurs.

The input power

frequency exceeds

the range.

Verify that the input

cables are

connected properly.

Verify that all the

three input phases

are present.

Loading...

Loading...