35

Power supply contactor becomes energized the moment

the torch trigger is depressed. Arcing can occur if the

wire is brought to a ground. Keep the torch away from

ground until welding is to begin.

C. To start the weld, hold the torch so the welding wire is

approximately 1/4-in. from the work, then press the

torch trigger.

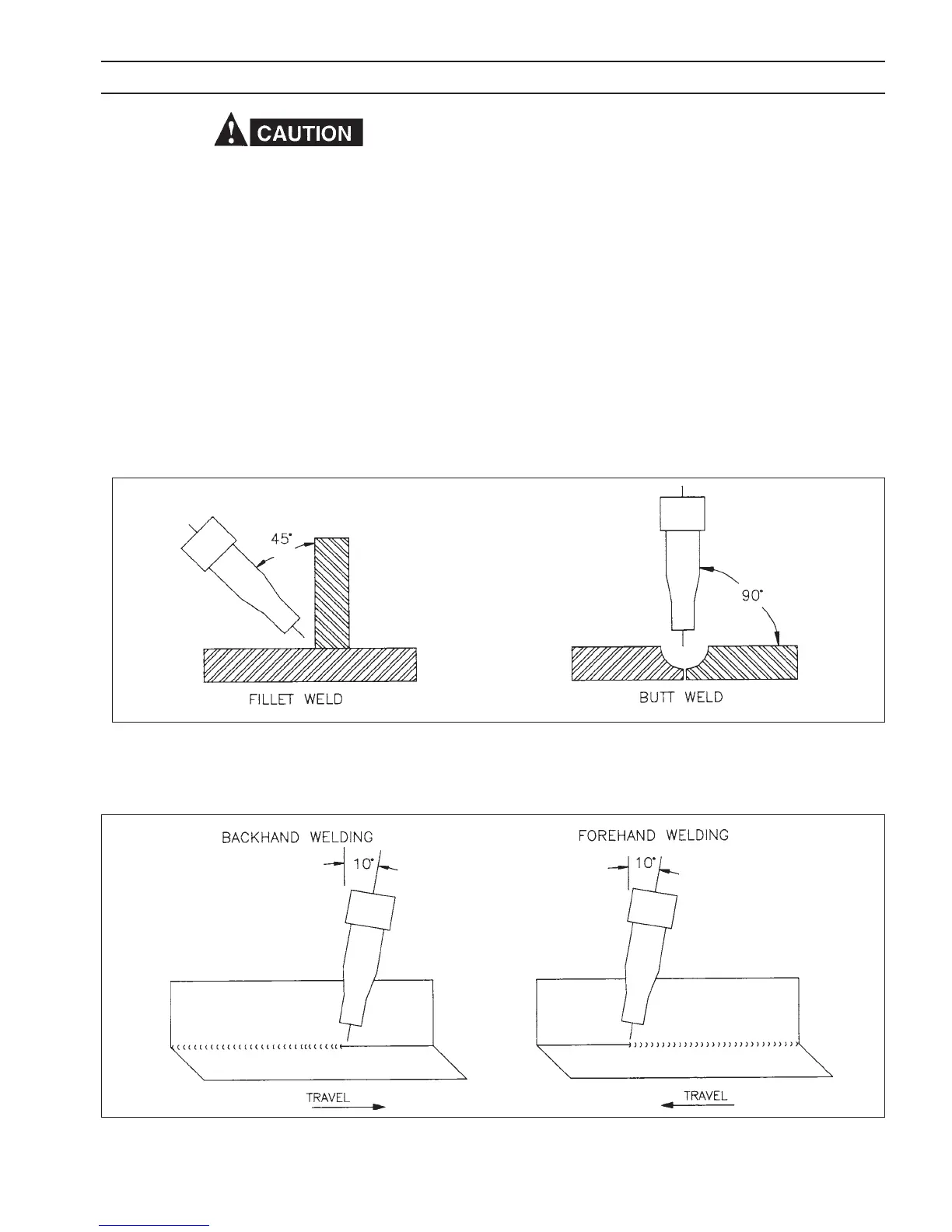

D. The welding wire should be pointed into the joint

at angles of approximately 45

0

for llet welds, and

approximately 90

0

for butt welds, (Fig 4.3.4.1).

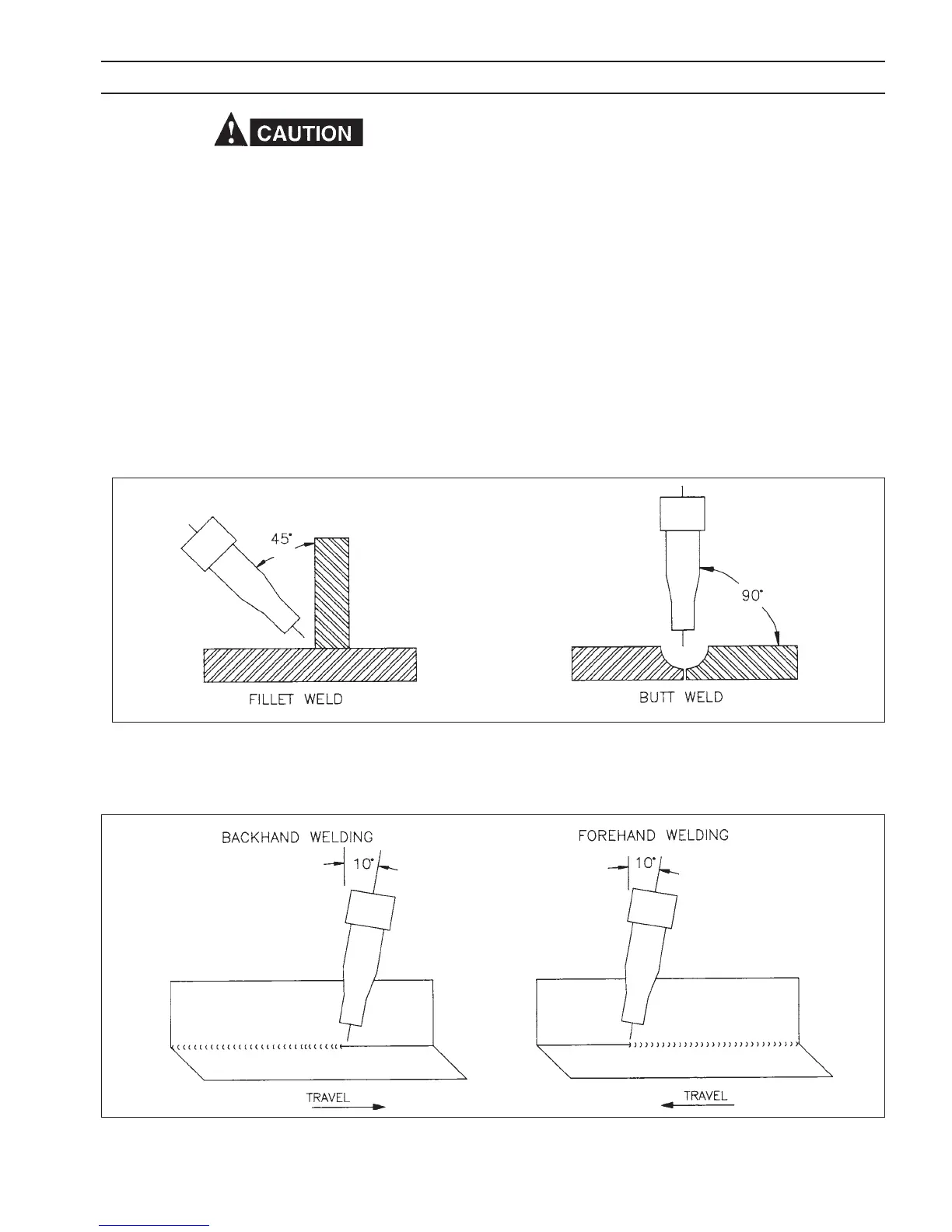

E. The torch angle relative to the length of the weld should

be approximately 10

0

from the vertical (Fig. 4.3.4.2).

F. When welding in the vertical position, traveling either

up or down, it is very important to keep the arc on the

leading edge of the puddle to ensure complete penetra-

tion.

G. Some welders who are accustomed to welding with stick

electrodes may tend to push the torch into the weld.

This is neither necessary nor desirable, since the wire

electrode is being mechanically fed into the weld.

Please note that the Wire Speed control can be adjusted

for the gauge of metal to be welded. However, the

Coarse Voltage Range and Fine Voltage setting must

not be switched while welding.

H. To stop the weld, release the trigger and pull the torch

from the work. When leaving equipment unattended,

always shut OFF and disconnect all input power and

shut o shielding gas at source.

TABLE 4.3, Continuous/Stitch Weld Conditions

Fig. 4.3.4.1 - Angle of Welding Wire with Joint

SECTION 4 OPERATION

Loading...

Loading...