-- 2 3 --

doce

4 OPERATIONAL DESCRIPTION

4.1 General

Switch on welding power source

The process controller can be used in manual or automatic mode.

In manual mode the wire feed speed and travel speed are controlled manually and

you can preset all other essential welding parameters for the current weld.

In automatic mode you can choose a preset group of welding parameters and

fine--tune the actual welding parameters. Other settings made previously in manual

mode cannot be adjusted in automatic mode.

The process controller is ready for manual operation as soon as the mains power is

switched on. When welding begins the controller switches to automatic mode. When

welding stops, or if there is a fault, the controller switches back to manual mode.

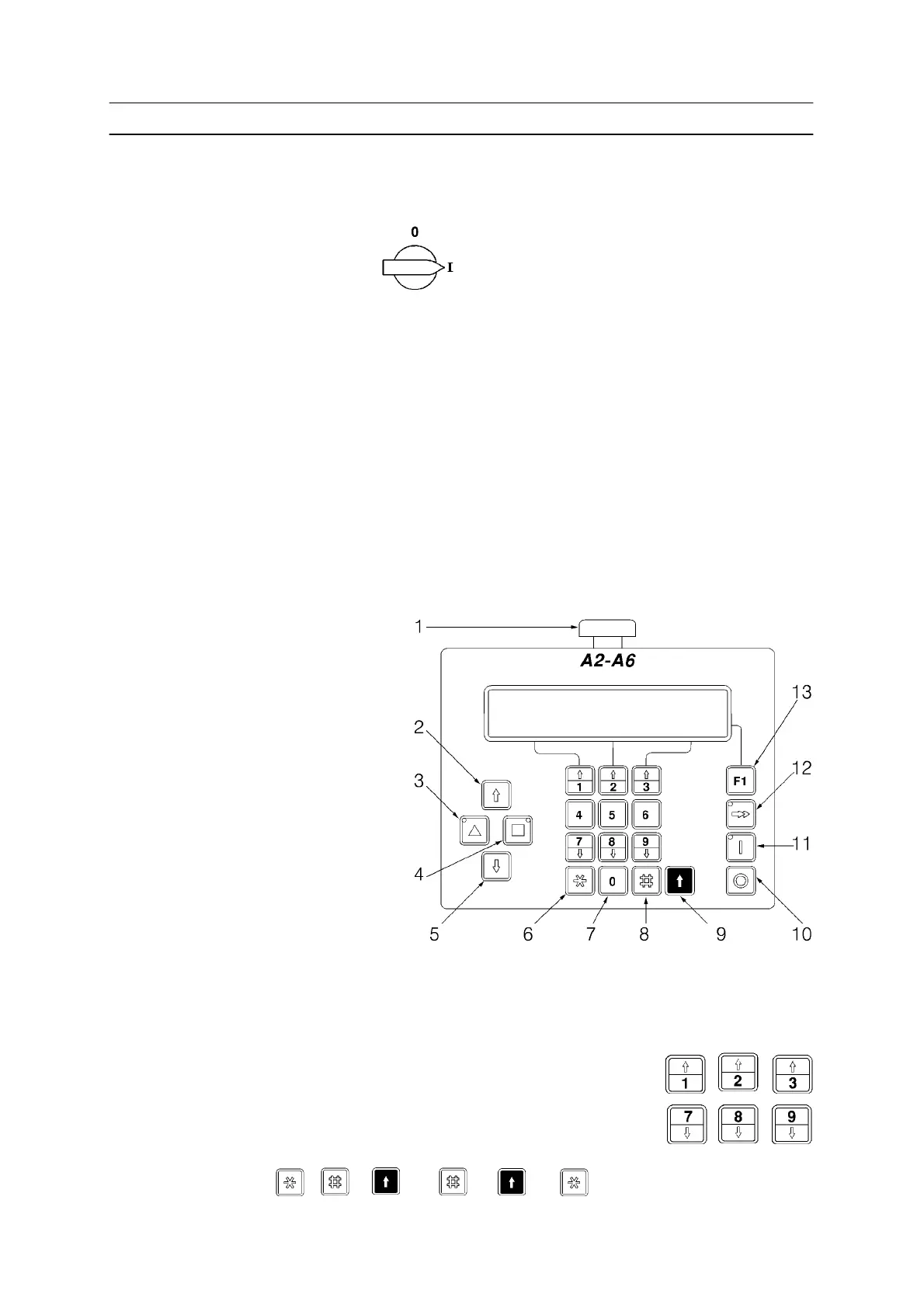

4.2 Control panel

1 Emergency stop

2 Retract wire

3 Travel

4 Travel, opposite direction

5 Advance wire

6 Change menu

7 Numerical key, number entry

8 ENTER key,

Change row

9 SHIFT key

10 Stop welding.

Return to manual mode

11 Start welding. Switch to automatic mode

12 Fast, wire feed or travel

13 Scroll page (welding setup menu) or close valve (main menu)

The arrowed keys are used during welding to increase or

decrease the current, voltage and speed.

By pressing either , ,

+

or

+

it is possible to browse.

Loading...

Loading...