-- 3 3 --

doce

Control

Two different operating modes can be used for welding, either constant current, CA,

or constant wire feed speed, CW.

S CA, constant current. Normally used for submerged arc welding, which involves

working with large welds, large currents and large weld pools. The wire feed

speed is controlled by the power source to maintain a constant current.

S CW, constant wire feed speed. Normally used for MIG/MAG welding, for small

weld pools, thin sheet metal and thin filler wire. It is easier to achieve a constant

throat thickness when welding with this method. Welding is controlled by

selecting a fixed wire feed speed and the current is adjusted to achieve this

speed. The resulting current is displayed above the selected wire feed speed

(see display shot on page 33).

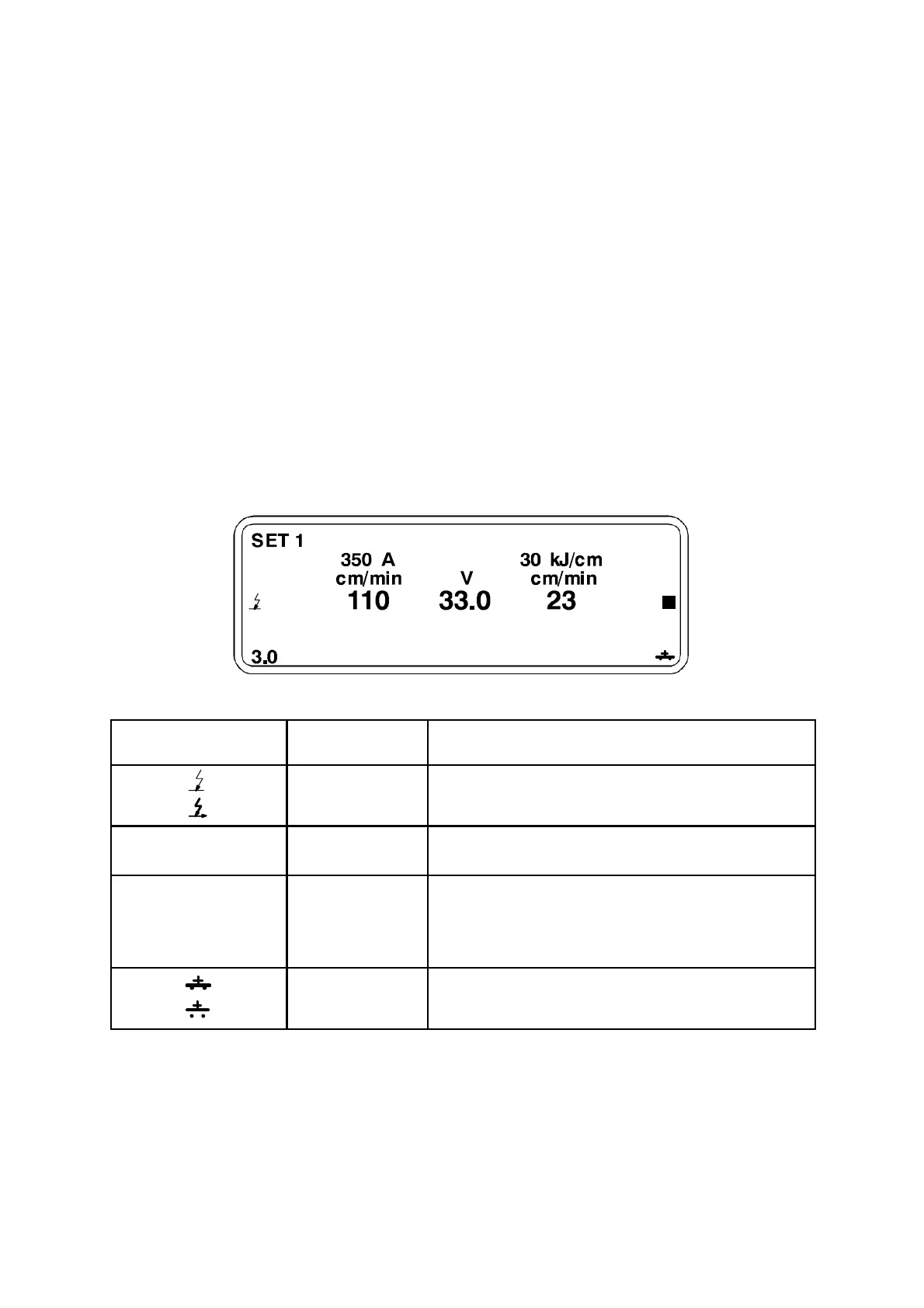

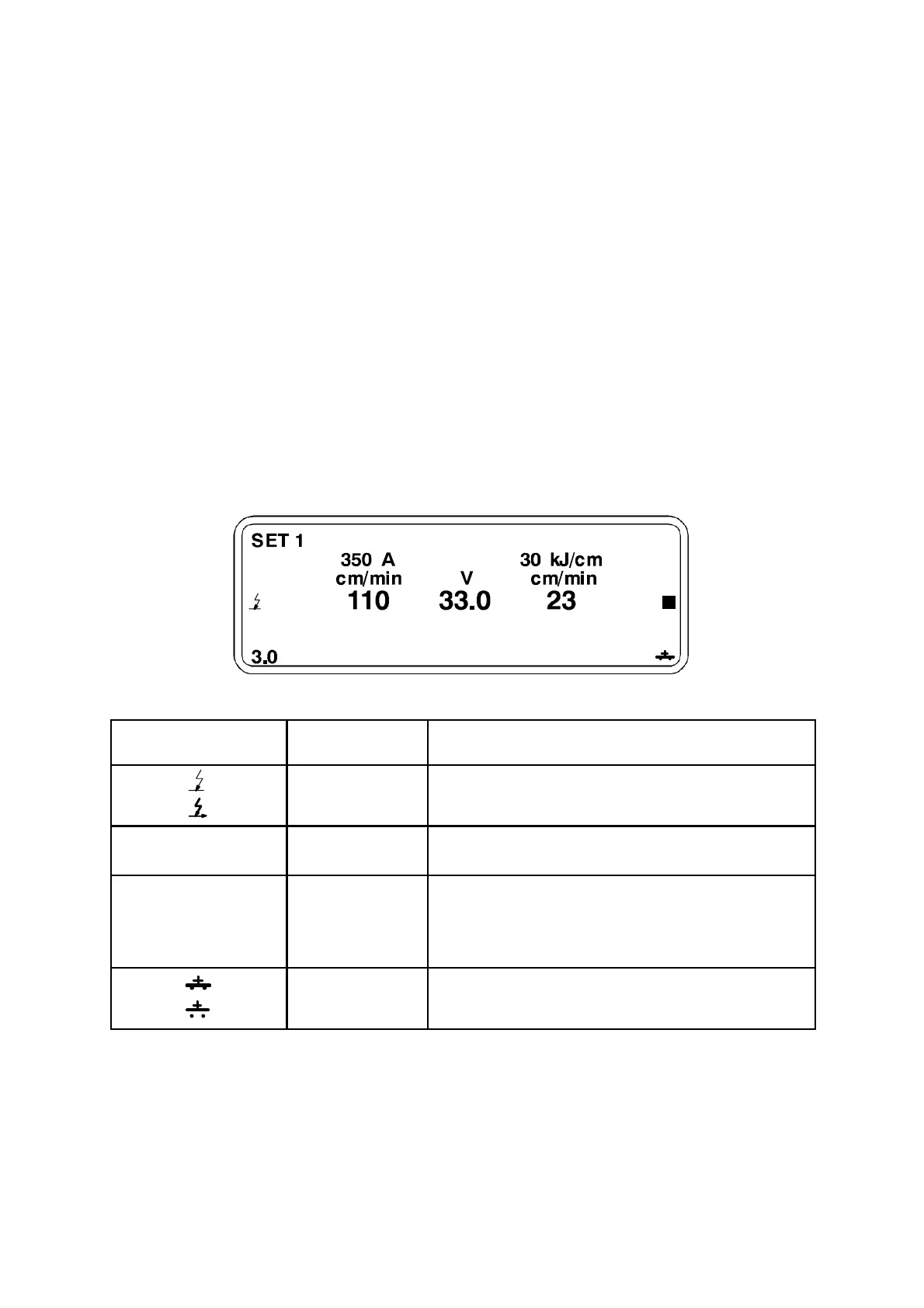

8.4 Preset indicators

The numbers and symbols on the display show the chosen preset values, see table

below.

Shown in display

“MAIN MENU” as

“WELDING SETUP”

options

Start Direct

Scratch

Y

J

Direction TRIANGLE

SQUARE

Shown in plain English

(e.g. 3.0)

Wire diameter:

Solid wire

Flux cored

Strip

0.8 1.0 1.2 1.6 2.0 2.5 3.0 3.2 4.0 5.0 6.0

0.81.01.21.62.02,43.03.24.0

30 x 0.5 60 x 0.5 100 x 0.5

OUTPUT

ON/OFF

Valve

Loading...

Loading...