Class II Biological Safety Cabinets

Chapter 4 - Maintenance

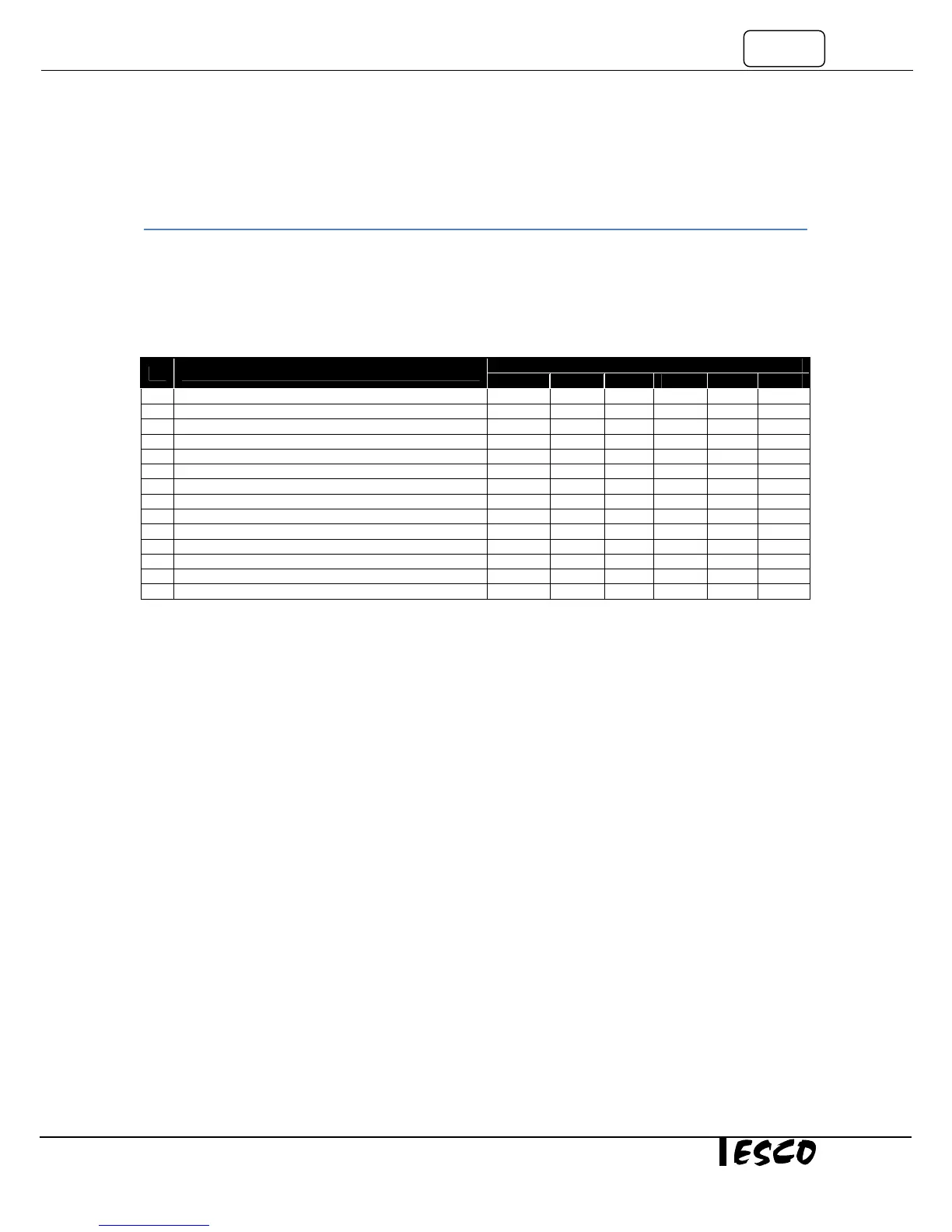

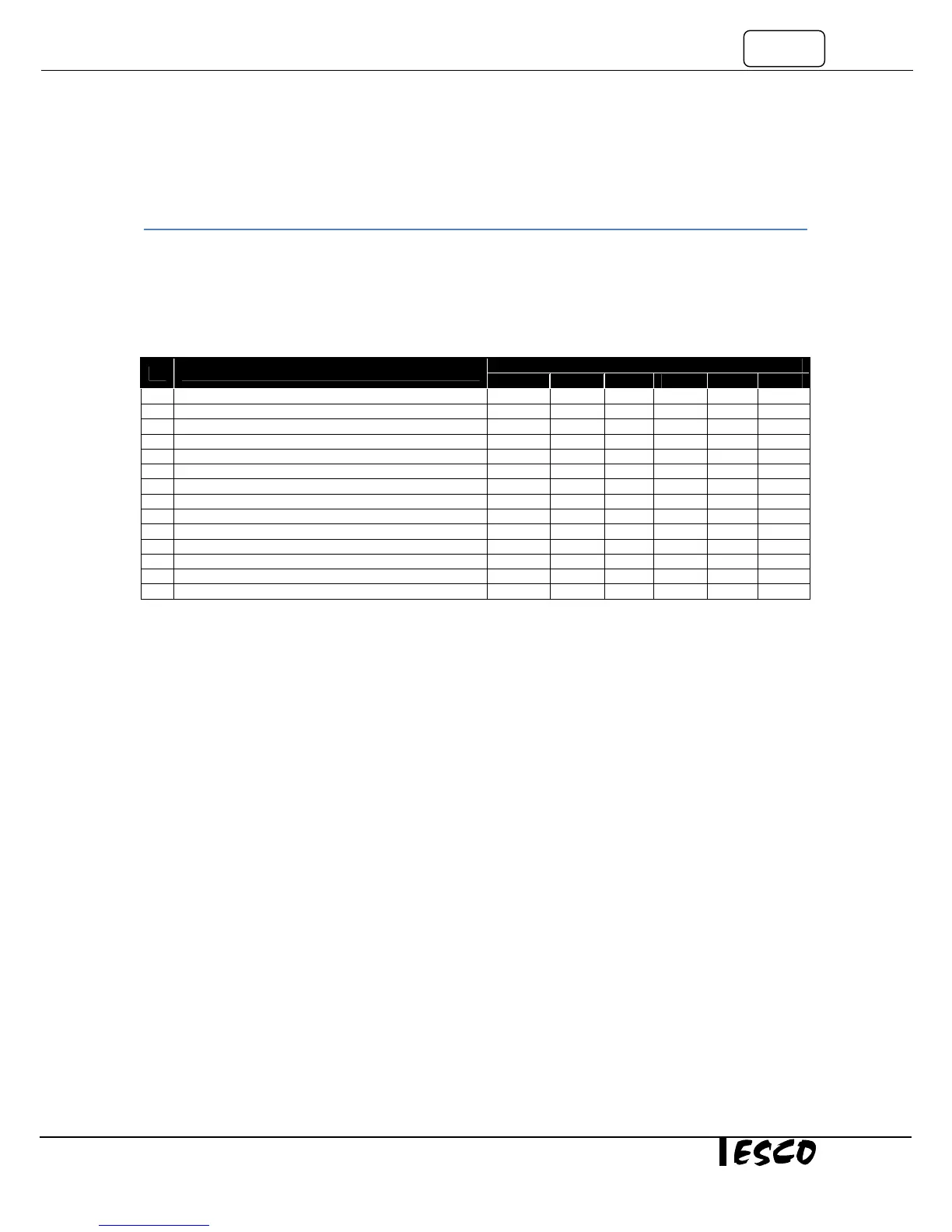

4.1. Scheduled Maintenance

Proper and timely maintenance is crucial for trouble-free functioning of any device and your Esco BSC is no

exception to this rule. We strongly recommend that you follow the maintenance schedule suggested

hereunder in order to obtain optimal performance from your Esco BSC.

No. Description of Task to Perform

Maintenance to be carried out every

Surface decontaminate the work zone

ce decontamination on the drain pan

Check the paper catch for retained materials

Clean UV lamp (where present) of any dust and dirt

Clean the exterior surfaces of the BSC

rvice fixtures (where present) for proper operation

Inspect the BSC for any physical abnormalities or malfunction

Clean stubborn stains on stainless steel surfaces with MEK

12 Check the cabinet’s functionality

√

Change UV Lamp (where present)

Change the fluorescent lamps

Cleaning the BSC

• Clean the work surface and walls with appropriate disinfectant and soap water afterward.

• Clean the sash window with appropriate disinfectant and glass cleaner afterward.

• Use a damp cloth to clean the exterior surface of the BSC, particularly on the front and top in order to

remove dust that has accumulated there.

• Use sterile water to finish the cleaning and wash away any residue of disinfectant, soap, water and

glass cleaner.

• For removing stubborn stains or spots on the stainless steel surface, make use of MEK (Methyl-Ethyl-

Ketone). In such cases, make sure that you wash the steel surface immediately afterwards with sterile

water and some liquid detergent. Use a polyurethane cloth or sponge for washing. Regular cleaning of

the stainless steel surface helps retain the attractive factory finish.

• Ensure that the chemicals used are compatible with one another.

• Use appropriate personal protective equipment (PPE) when carrying out the activity.

Test the audible and visual alarm

The simplest method by far would be to move the sash until the glass window is no longer in the sash ready or

UV mode position.

Check the cabinet’s functionality

• Check the BSC’s mechanical functionality (e.g. sash window – lubricate if necessary).

• Check the BSC’s electrical functionality (e.g. fluorescent lamp – replace if necessary).

• Check the BSC for any defect and if any, repair immediately.

Recertification

All BSCs must be re-certified annually by a certified engineer. See certification procedures attached to the

factory test report.

Loading...

Loading...