Class II Biological Safety Cabinets

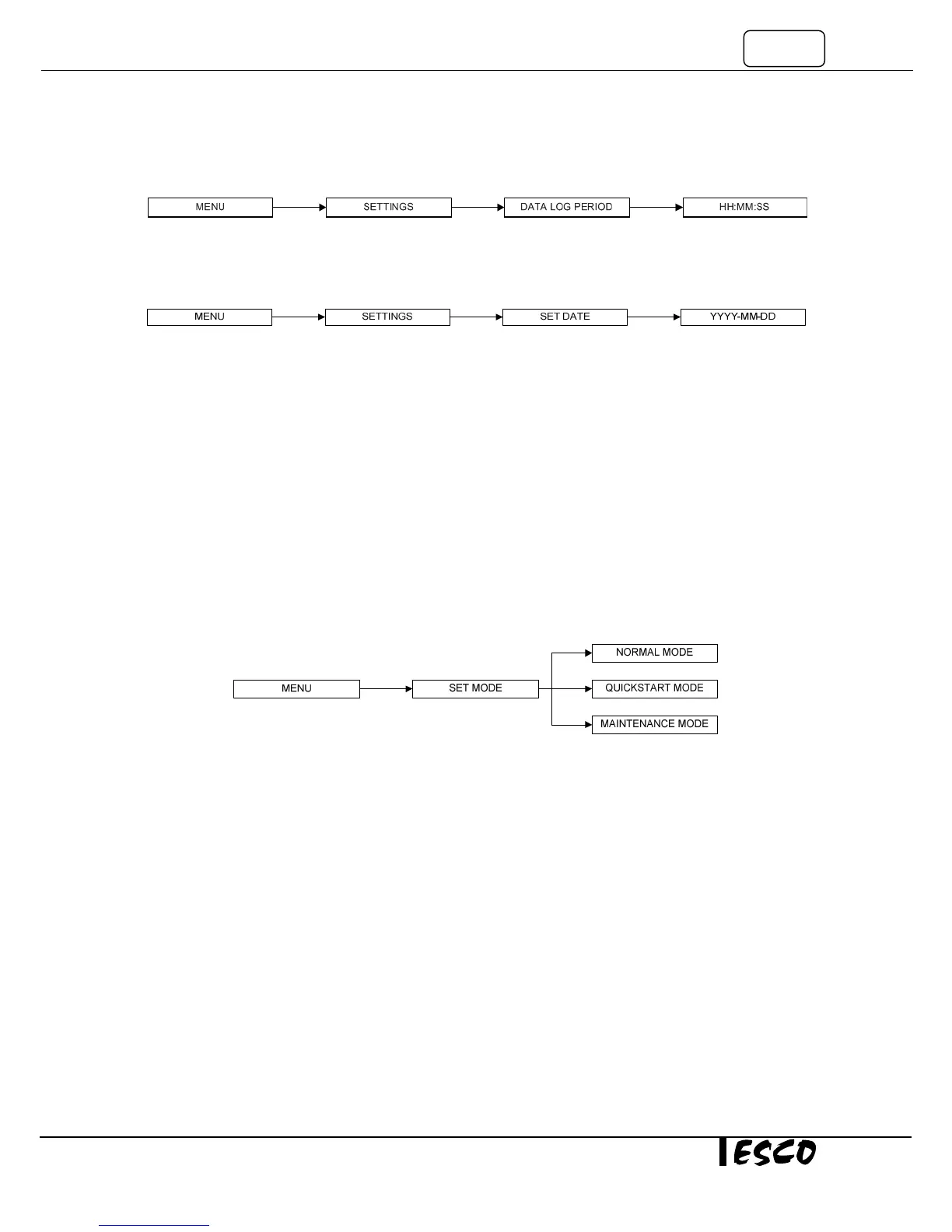

2.2.1.7. Data Log Period

Using RS232 communication port, the BSC can send data on the condition of the BSC to a PC. Data Log Period

option allows the user to control the amount of time within the BSC data sending procedure.

2.2.1.8. Set Date

Users can set the date by increasing/decreasing the year, month and day values. The correct date will be

maintained even after the unit is turned off.

To Set Date:

1. Press MENU button to enter the menu display – if the BSC is secured by a FAN PIN, then it will ask for

the PIN, otherwise go to step 3.

2. Use UP / DOWN button to enter the FAN PIN or ADMIN PIN digit by digit. Press SET button to confirm.

3. The alarm buzzer will sound.

4. Use UP / DOWN buttons to choose SETTINGS. Press SET button to confirm.

5. Use UP / DOWN buttons to choose SET DATE. Press SET button to confirm.

6. The time is set in YYYY–MM–DD format. Use UP / DOWN buttons to choose the year (YYYY). Press SET

button to confirm. Do the same for the month and day.

7. The display will show DATE SET for a few second and then return to SETTINGS.

8. Press MENU button twice to return to the main display.

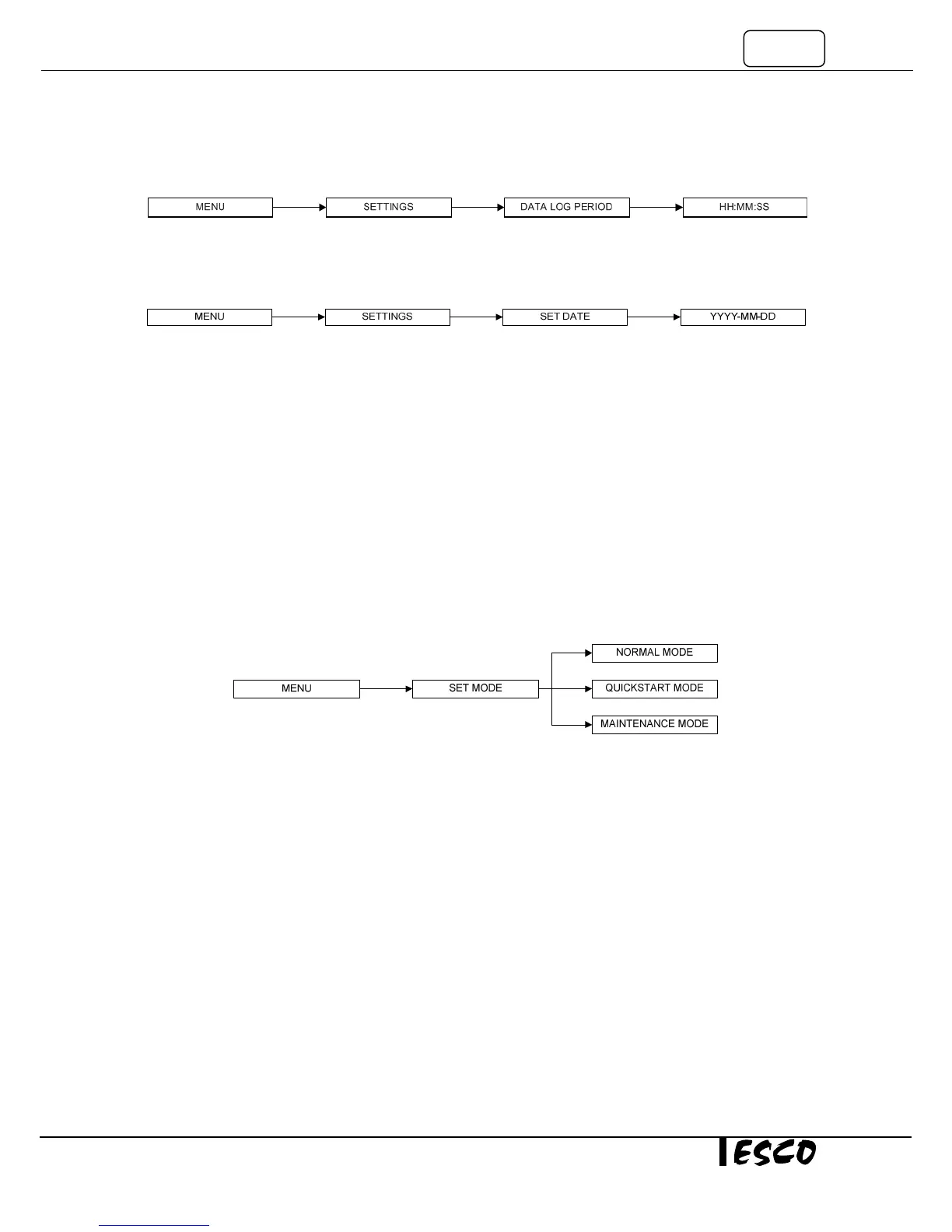

2.2.2. Setting Mode

The BSC has three modes and two of which, normal mode and quickstart mode, can be used in daily activity.

Both of these modes can be seen and accessed when you enter the FAN PIN. The last mode, maintenance

mode is for the use of qualified personnel during maintenance.

2.1.2.1. Normal Mode

The Normal mode is activated by factory default except N series. In this mode, all alarms and interlocks are

enabled.

2.2.2.2. Quickstart Mode

Quickstart mode allows the user to activate the blower by simply lifting the sash from fully closed position and

the light by simply lifting the sash window to the operating position. In this mode, all alarms and interlocks are

enabled. This mode is activated by factory default in N series.

2.2.2.3. Maintenance Mode

Maintenance mode should only be accessed by qualified personnel during maintenance. In this mode, all

alarms are disabled and all interlocks are defeated.

2.2.3. Field Calibration

The purpose of calibration is to ensure the accuracy of the airflow display and alarm (if present). This involves

measuring airflow with reference instrumentation and establishing reference between airflow sensor(s) on the

BSC to the standard reference. Calibration should only be carried out by qualified personnel. This section

presents a brief overview of the calibration menu function. For more information, refer to test report.

Loading...

Loading...