Parallel or serial connection

between several buffers

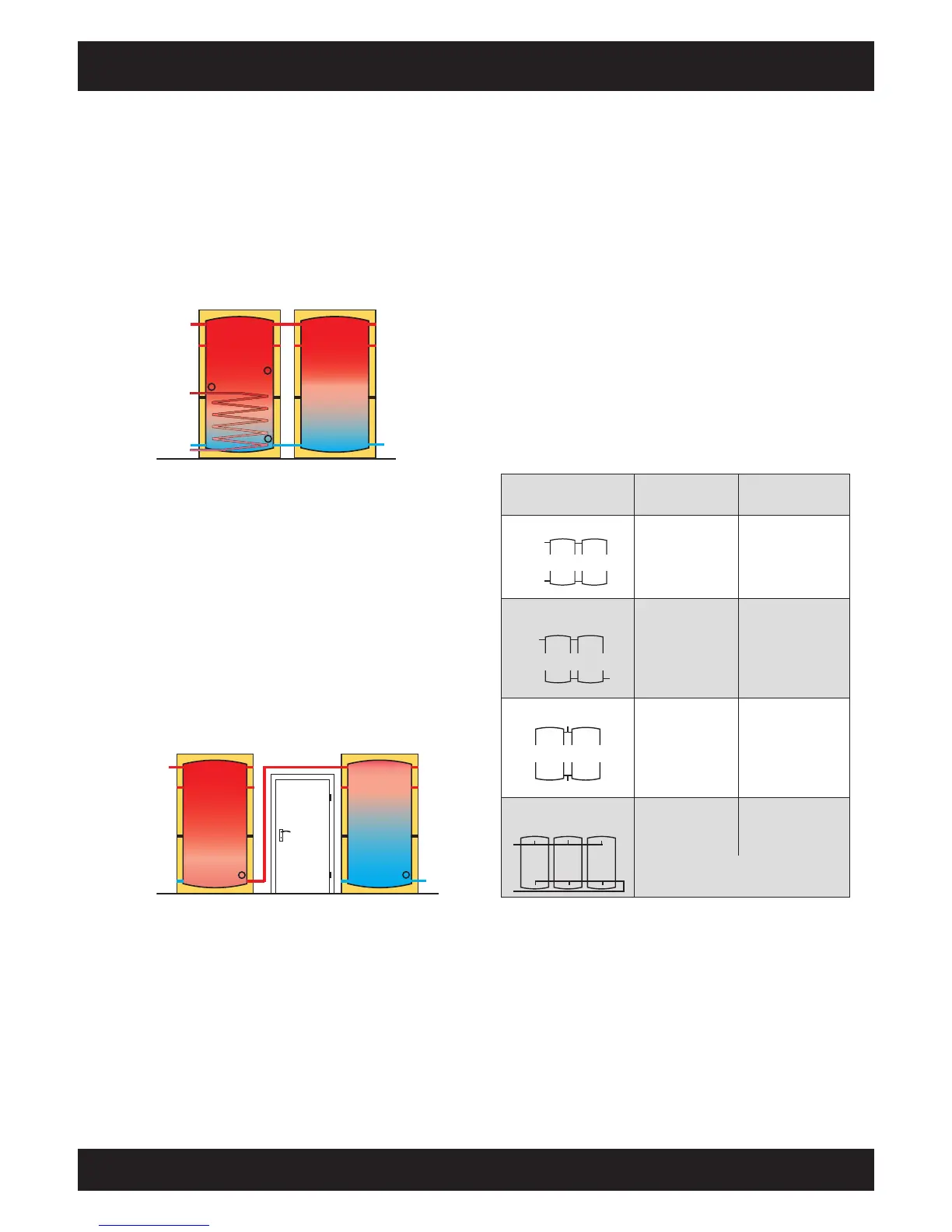

When there are several buffers, normally the parallel

connection (top with top and bottom with bottom)

is the better solution.

With a parallel connection, the entire buffer volume

is available to installed heat exchangers such as solar

heat exchangers or internal water heat exchangers

and suspended hot water tanks.

(Return)

Flow

Solar return

Solar flow

If two buffer storage tanks of different dimensions

are connected in parallel, then the flow must be

connected to the higher one or the lower one must

be raised so that the upper connection can be

horizontal.

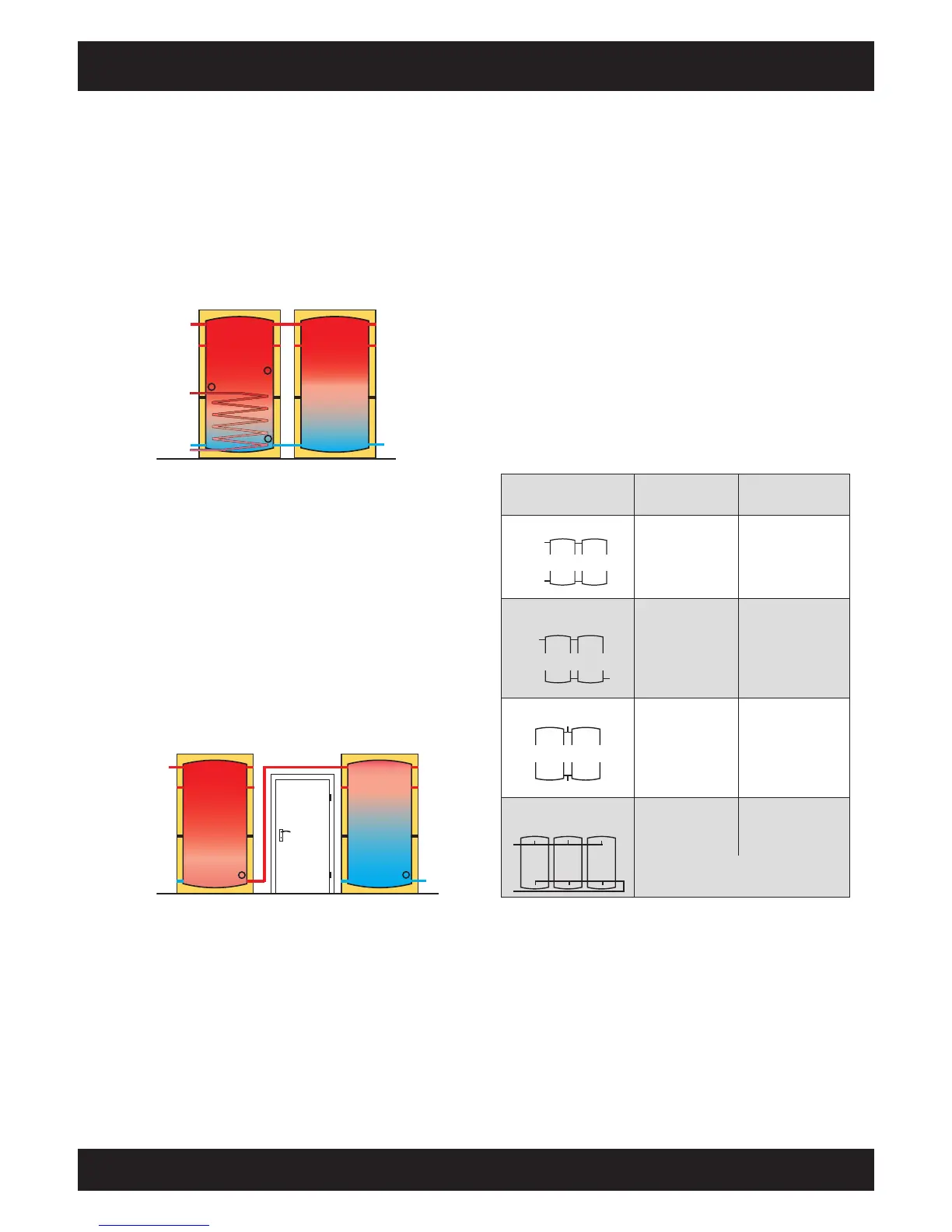

A serial connection between two buffers has no

advantages over a parallel connection; if anything

it is a disadvantage. For example, a suspended

hot water tank can get no heat from the second

buffer or an internal heat exchanger cannot heat

on both buffers. For this reason, with serial buffers

one should connect a solar supply using either

heat exchangers in both buffers or better with an

external heat exchanger.

With rare exceptions, the use of the serial

connection (buffer 2 top and buffer 1 bottom

connected) is limited to overcoming spatial obstacles

in the given installation situation. Only a serial

connection is possible if the passage to a door

needs to be kept free or for large distances between

buffers.

Tichelmann connection for higher outputs

For parallel connection with one-sided connection,

the volume of the second buffer is integrated via

thermosiphon principle. The exchange between

the two tanks is driven only by gravity and limited

by the hydraulic resistance of the junctions, so

for medium outputs a Tichelmann connection is

required.

With a 6/4" connection, a maximum of 5,500 l/h

at 0.25 mH

2

O pressure loss is possible (for flow and

return connections together). This corresponds to

130 kW at a spread of 20°C. Therefore, for higher

outputs external piping, either symmetric or with

Tichelmann connection, is needed.

With more than two tanks, external piping with

Tichelmann connection is also needed to fill and

drain all tanks uniformly.

Parallel buffer storage

tanks

Buffer connections

5/4" DN32

Buffer connections

6/4"

DN40

one-sided connection

up to 25 kW

boiler output

up to 40 kW

boiler output

internal

Tichelmann connection

up to 80 kW

boiler output

up to 130 kW

boiler output

Symmetric connection

for more than

80 kW boiler output

for more than

130 kW boiler output

external piping with

Tichelmann connection

for more than

80 kW boiler output

for more than

130 kW boiler output

and/or

for more than two buffer storage tanks

Flow

Return

Flow

Return

Flow

Return

Maximum 2 buffers

Maximum 2 buffers

Flow

Return

Maximum 2 buffers

Buffer storage tanks demand softened water

If buffer storage tanks are installed in a heating

system, the system must be filled with softened

water. Around 0.25 kg of limescale will precipitate

from a cubic metre of water with 15° of German

hardness.

Loading...

Loading...