14

Operation and Maintenance Instructions

If the water diffusers are not functioning properly, it is a sign that the suction strainer has not been working properly and that foreign

matter or dirt has accumulated in the water distribution pipes. The nozzles can be cleared by taking a small pointed probe and

moving it back and forth in the diffuser opening.

If an extreme build up of dirt or foreign matter occurs, remove the end cap in each branch to flush the debris from the header pipe.

The spray branches and header can be removed for cleaning, but should only be done if absolutely necessary.

After the water distribution system has been cleaned, the suction strainer should be checked to make sure it is in good operating

condition and positioned properly so that cavitation or air entrapment does not occur.

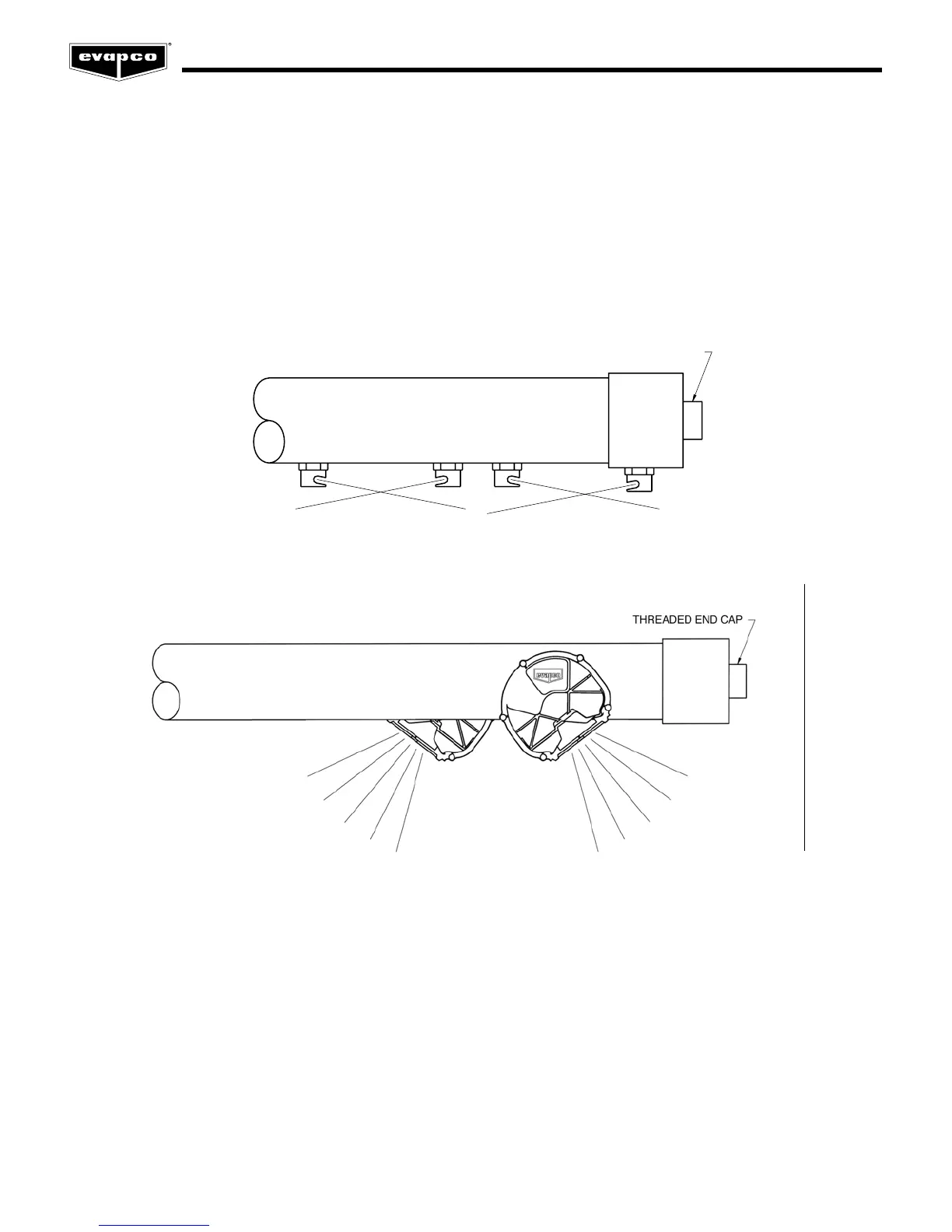

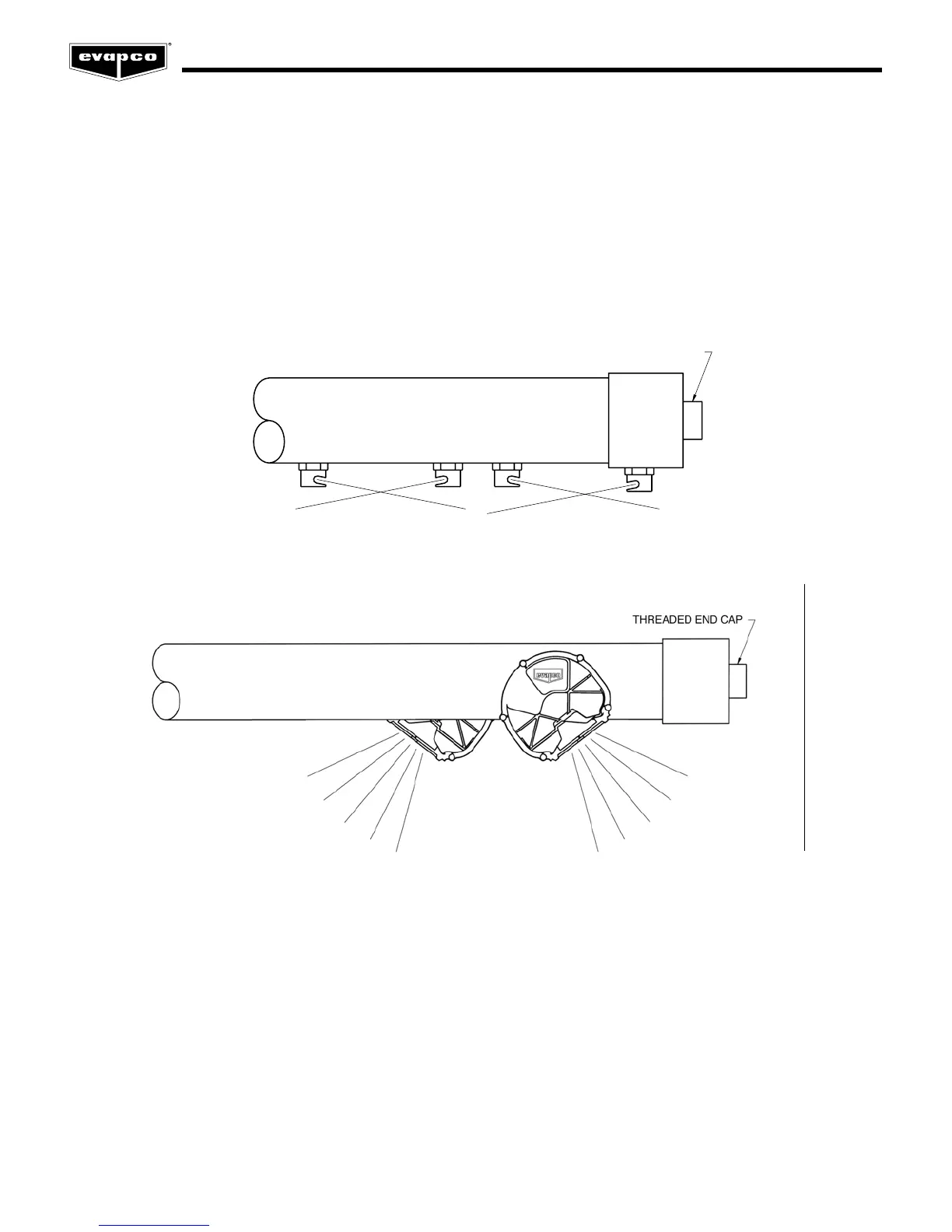

When inspecting and cleaning the water distribution system, always check that the orientation of the water diffusers is correct as

shown below for LSTB, LPT and LSTA models in Figure 10 and as shown in Figure 11 for AT, USS and UT models. The top of the

EVAPCO logo on the nozzle is parallel with the top of the water distribution pipe.

THREADED END CAP

Figure 10 – LSTA/LSTB/LPT Water Distribution

Figure 11 – AT/USS/UT Water Distribution

UNIT

END WALL

Loading...

Loading...