EVCO S.p.A.

EV3 MVC & EVD MVC | Application manual ver. 1.0 | Code 144EV3MVI104

page 50 of 72

Treatment coils

The controller is able to manage one or two coils for heating and cooling of the air emitted into the environment. The purpose of these

coils, together with the recovery heat exchanger, is to guarantee that the ideal temperature is maintained in the air-conditioned

environment.

The first coil can be hot, cold or reversible according to parameter C30. The second coil can only be hot and can be used as:

- The single heating source (in the winter cycle) if the first coil is cold only and as post-heating in the summer cycle

- The second heating level (in the winter cycle) if the first coil is hot or reversible, always as post-heating in the summer cycle

if the first coil is reversible (if the first coil is hot dehumidifying is not possible and therefore post-heating does not apply).

The coils are allocated according to the resources used.

The types of coils managed are as follows:

-

Direct expansion coil: can be hot, cold or reversible according to parameter C30. It uses the Compressor relay

- Three-point water coil: can be hot, cold or reversible according to parameter C30. It uses the Open water valve and Close

water valve relays. The duration of the valve action is determined by parameter C33

- ON-OFF water coil: can be hot, cold or reversible according to parameter C30. It uses the Open water valve relay

- Modulating water coil: can be hot, cold or reversible according to parameter C30. It uses the water valve analogue output

configured as analogue output 0-10 V and the Open water valve relay to enable (optional)

- One or two step electric coil: can only be hot. It uses the Step 1 heater and the Step 2 heater relays

- Modulating electric coil: can only be hot. It uses the heater analogue output configured as analogue output 0-10 V or a

triac/OC output configured as heater. The Step 1 heater is used to enable. If parameter C31 (heater activation period) is

greater than 0, the analogue output is controlled in PWM with this period (in seconds) and with the maximum output signal

amplitude determined by parameter C32. For example, if C31=10 seconds, C32=8 V and regulation with 50% regulation, the

output signal takes on the value 8 V for 5 seconds and the value 0 V for another 5 seconds. If however, C31=0 the output is

modulating (where the output voltage corresponds to the percentage of heat regulation required).

N.B. the electric coils are only switched on when the time A06 (flow alarm bypass) has elapsed from when the fans are

switched on to guarantee airflow and avoid any possible overheating problems.

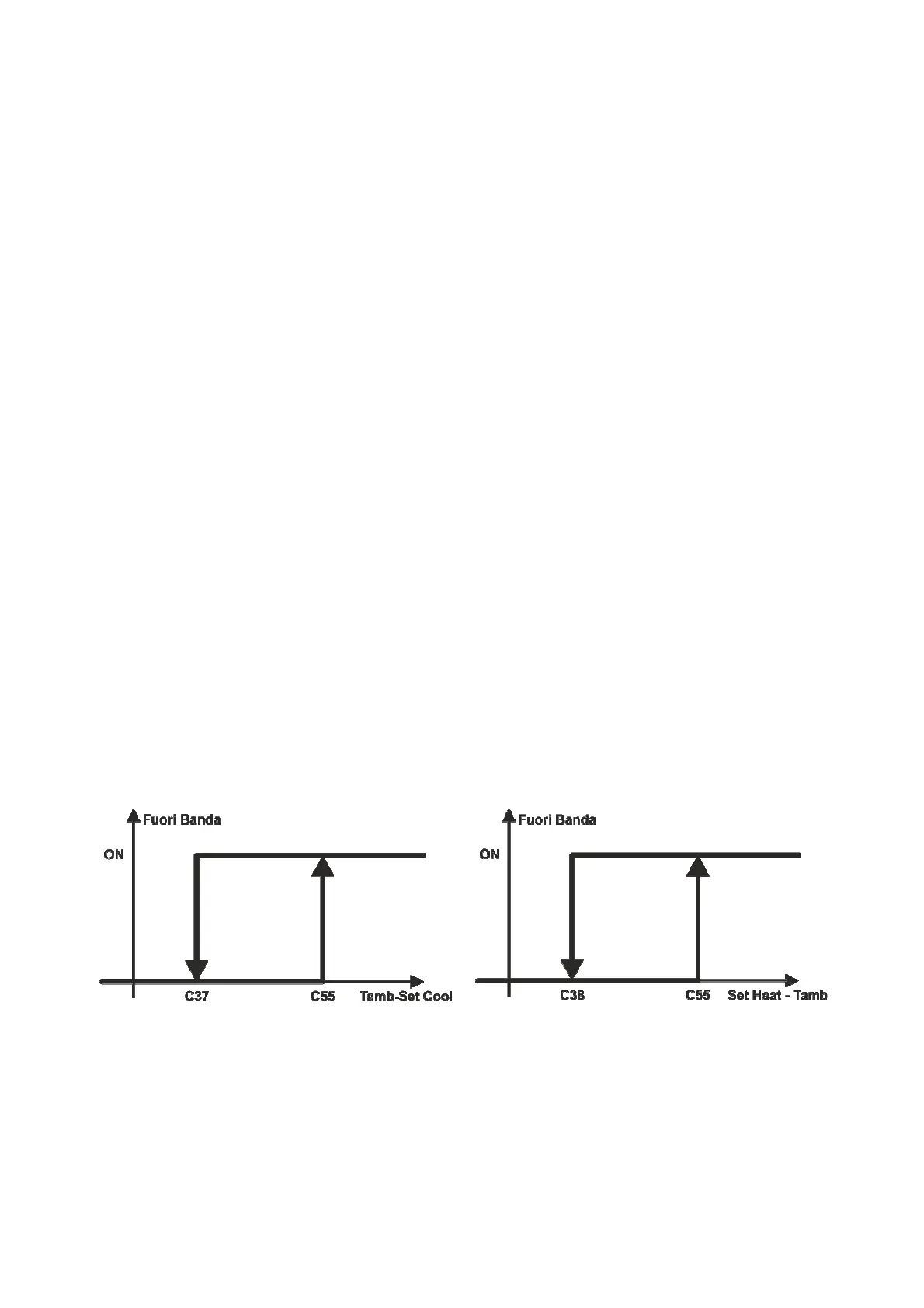

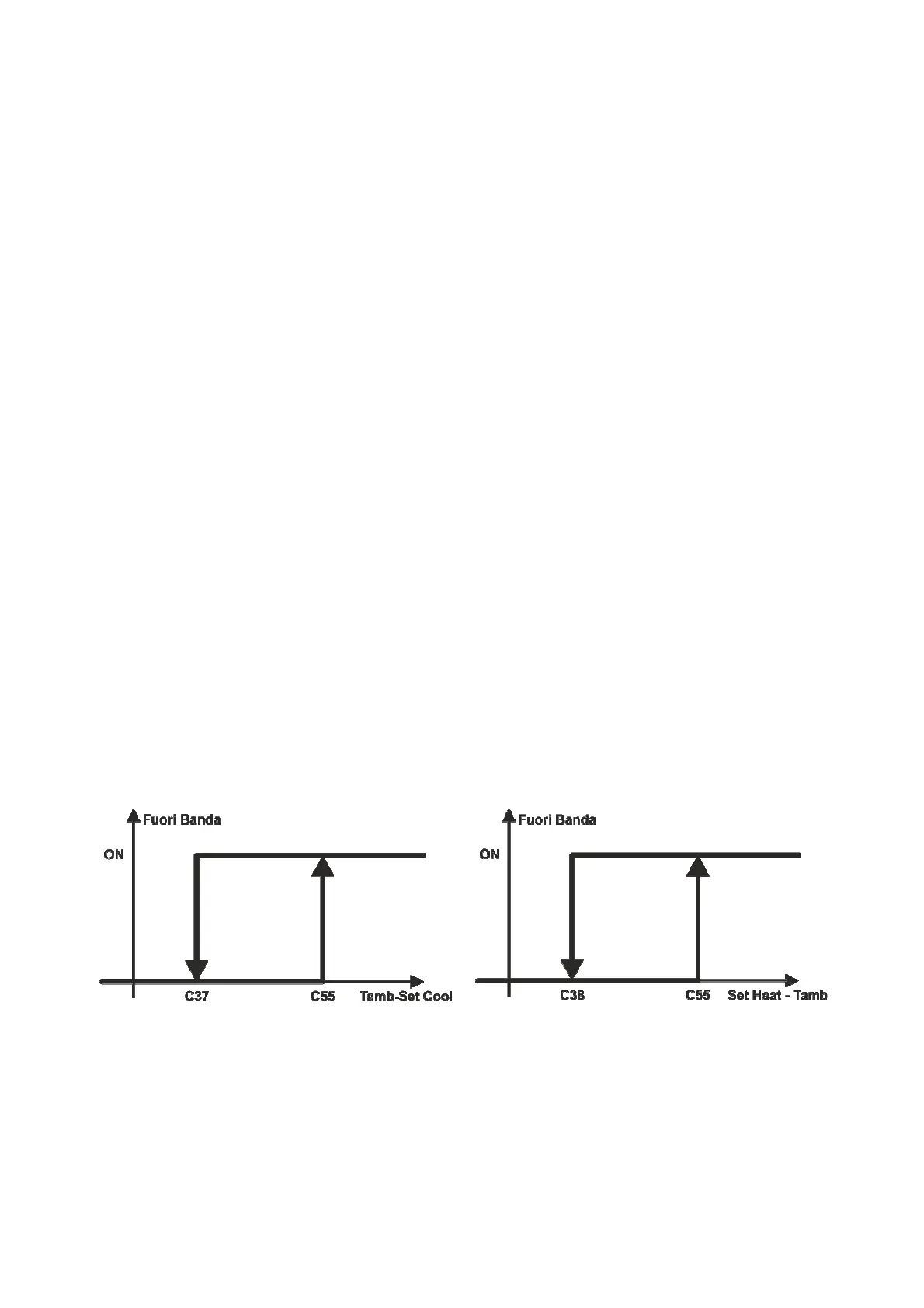

Off-band mode activation

This mode is activated if the room probe is configured and not in alarm mode and if the mixing chamber damper is configured.

The room temperature is considered off-band if this is outside the comfort zone (<Hot setting – Comfort band (C55) in heating; > Cold

setting + Comfort band (C55) in cooling).

The effect of off-band mode is to close the mixing chamber damper so as to speed up the return to the temperature regulation band.

The mode is deactivated if the room temperature comes close to the active regulation setting returning within the normal active

regulation band (C37 in heating, C38 in cooling) as shown in the diagrams.

Cooling Heating

9.8 Regulating the compressor

The controller can manage an ON-OFF compressor that can be used as either a first hot/cold/reversible regulation coil teamed with a

cross-flow or rotary recovery heat exchanger or a thermodynamic recovery heat exchanger as an alternative to the other types of heat

exchangers. As compared to the other types of coils and recovery heat exchangers, the safety features listed below should be taken

into consideration for managing the compressor:

- Minimum time between switch-on (C29) and switch-off (C28)

- Safety inputs (high and low pressure, compressor thermal switch, discharge temperature, etc.).

In order for the compressor to function as a thermodynamic recovery heat exchanger (active in both heating and cooling mode) or as a

reversible coil, an inversion valve digital output must be configured to allow the refrigeration circuit to function in both modes.

Loading...

Loading...