EVCO S.p.A.

EV3 MVC & EVD MVC | Application manual ver. 1.0 | Code 144EV3MVI104

page 51 of 72

When the mode is changed (from hot to cold or vice versa) the compressor, if activated, is switched off and the valve inverted.

Another feature of the compressor is the need for defrosting that may be managed in such a way as to remove ice that has formed in

the coil as described in the paragraph below.

During the active defrost phases the refrigeration circuit function is inverted. To retain the heat localised on the coil that needs

defrosting and to avoid both pressure imbalances and emitting freezing air into the environment, both fans are switched off.

N.B. the compressor is only switched on when the time A06 (flow alarm bypass) has elapsed from when the fans are switched on to

guarantee airflow and avoid any possible imbalances.

Defrosting the refrigeration circuit

In order to determine both when it is necessary to perform a defrosting cycle and to end this, the probe located on the coil

(

Compressor defrost probe)

is used according to the parameters governing this function, d01-d08.

According to the parameter d01 value, defrost can be:

d01 = 0 Defrost not enabled

d01 = 1 Defrost by temperature, described below

When the compressor is active and value detected by the probe located on the coil falls below d02, a counter begins and when this

reaches a value of d03 the defrost cycle is activated. If during counting the temperature returns to above d02 or if the compressor is

switched off, the count is suspended. If during counting the temperature detected by the probe falls below the value d08 defrost is

activated with a wait reduced to 10 seconds.

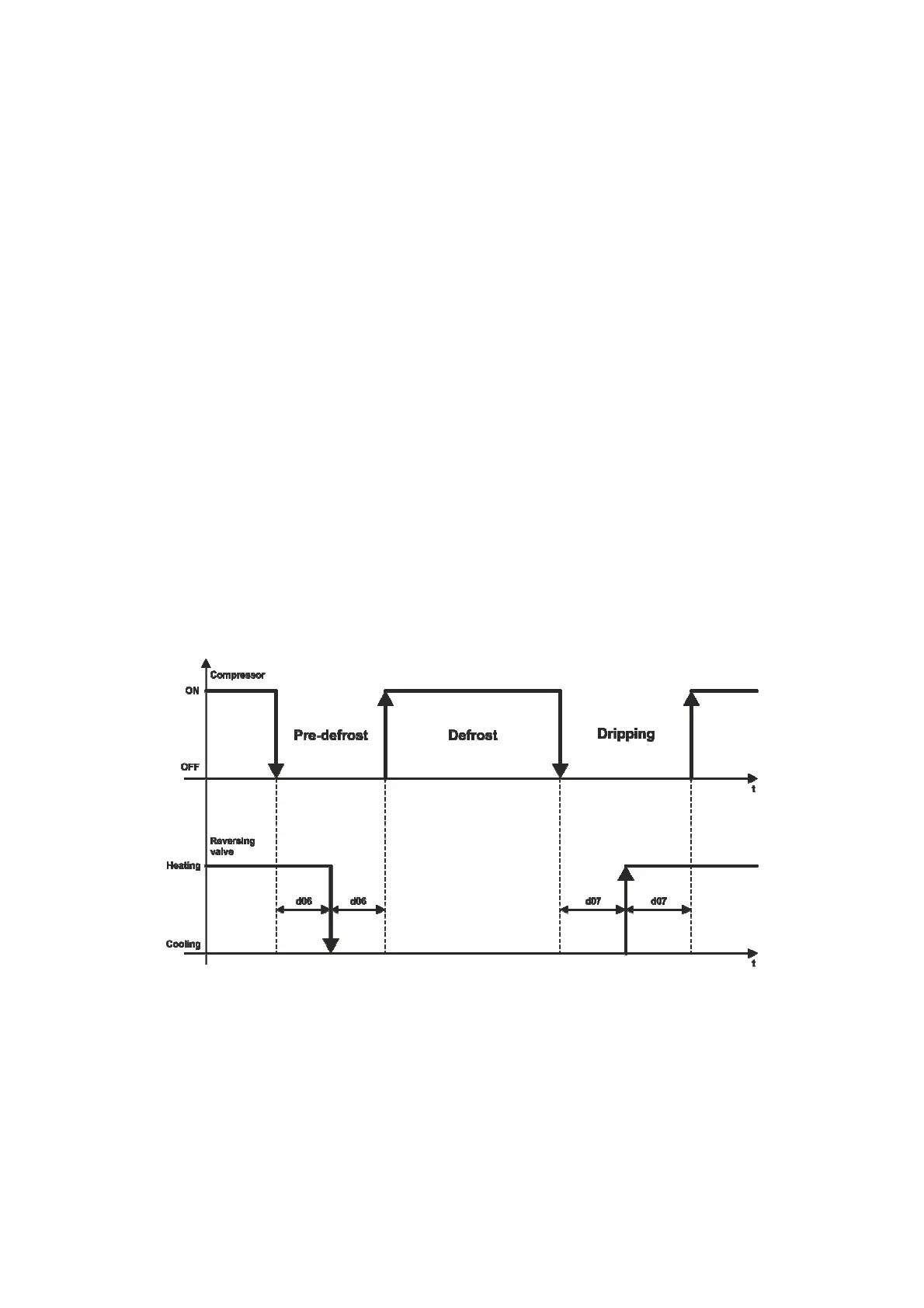

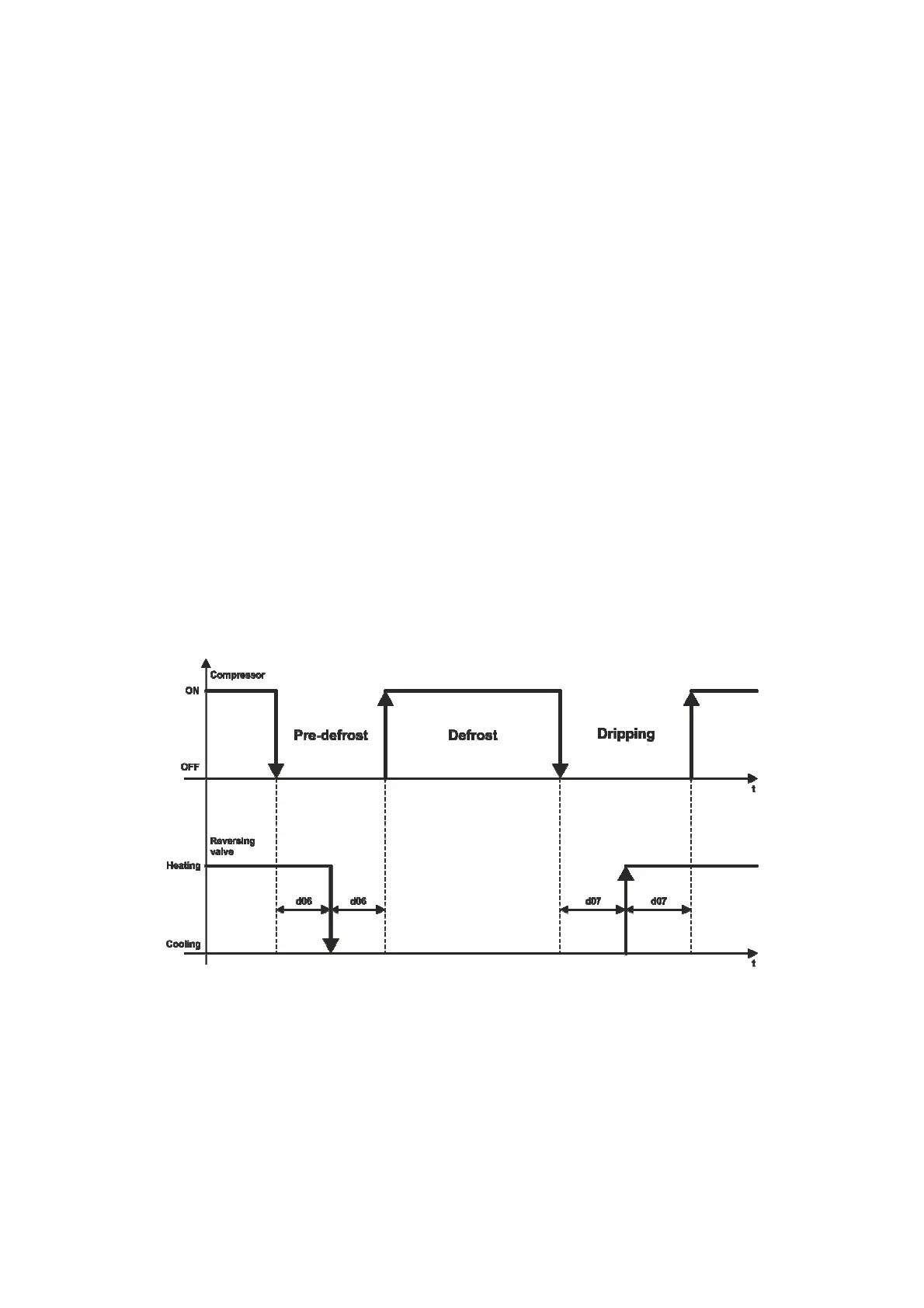

When the defrost cycle starts up the compressor is switched off for the d06 time, at the end of which this switches the reversing valve.

After a further d06 period the compressor is reactivated for the active defrost cycle phase. The purpose of the waiting time 2xd06 is to

balance the pressures in the circuit. This could also be zeroed if a running defrost is required.

The compressor remains on until the temperature detected by the probe on the coil rises above d04, in which case the active phase

comes to an end. If this situation is not achieved within the d05 time the active defrost phase is still concluded but the compressor is

switched off. After this the drip phase begins, after d07 the reversing valve switches to heating status and after a further d07, the

compressor is reactivated in heating mode.

The diagram below shows the way in which the defrost by temperature happens.

d01 = 2 Defrost by compressor off, described below

To defrost the coil the compressor is switched off, in which case the fans remain on and the warm expelled air removes the ice.

Compared to the last process, this one avoids the active phase of the defrost cycle (compressor on with reversing valve in cooling

position).

d01 = 3 Time defrost, described below

In this situation everything works as for d01=1 apart from the exit from the defrost active phase that is always determined by the

maximum time (d05).

Loading...

Loading...