BEVEL ANGLES (0

0

AND 45

0

)

0

0

Bevel Stop Adjustment

• Ensure that the Cutting Head is in the locked down position

with the latching pin fully engaged in its socket.

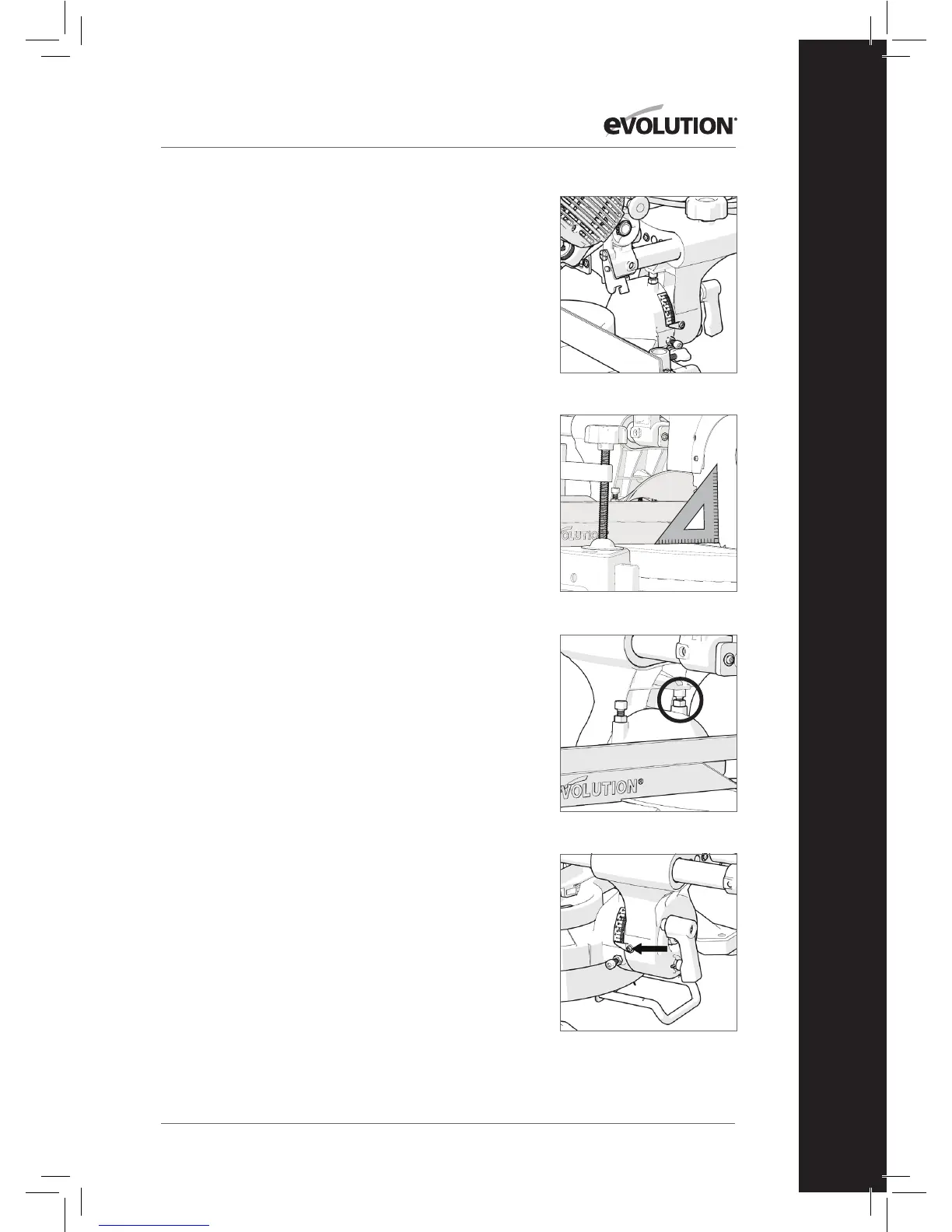

• Ensure that the Cutting Head is upright, against its stop and

the bevel pointer is indicating 0

0

on the scale. (Fig. 12)

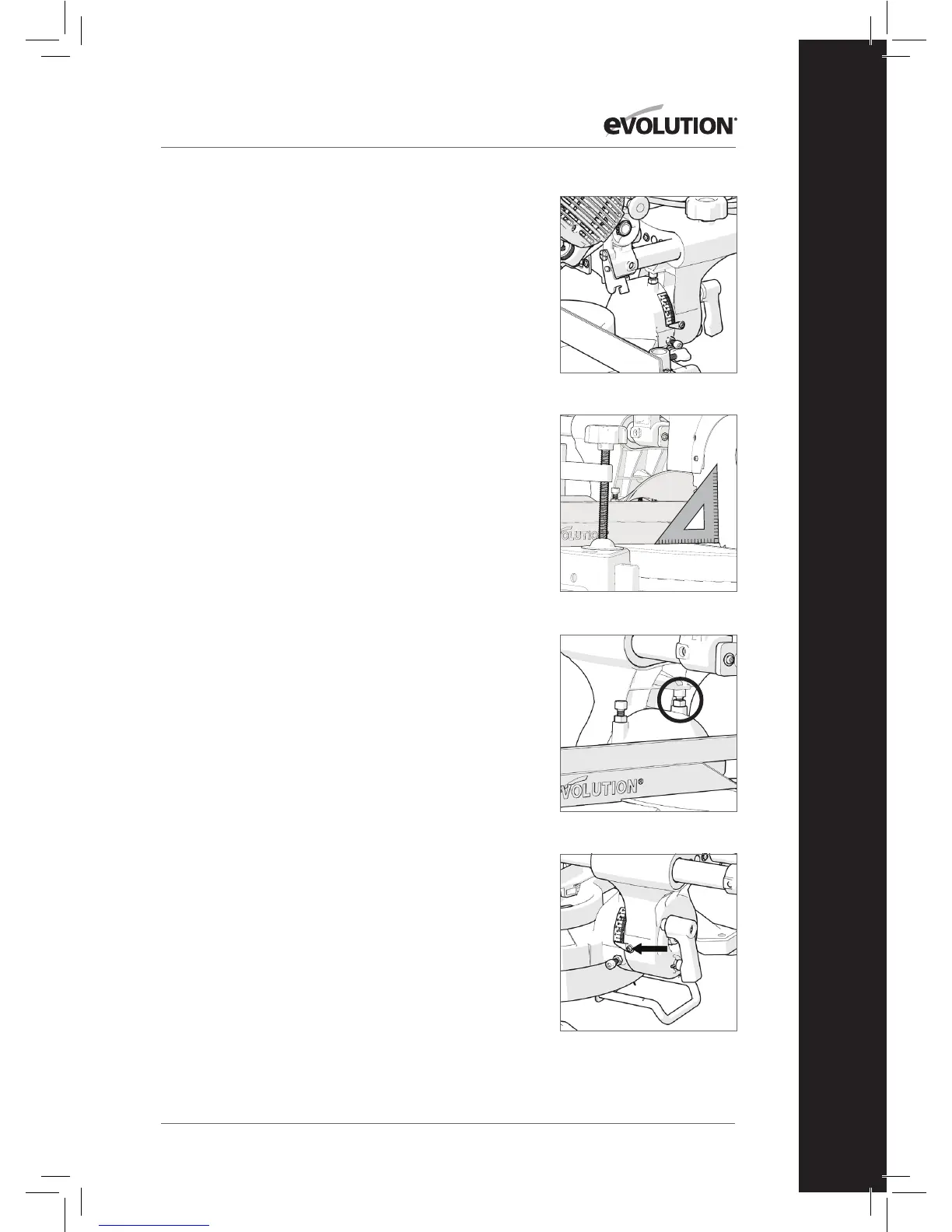

• Place the Set Square on the table with one short edge

against the table and the other short edge against the blade

(avoiding the TCT tips). (Fig. 13)

• If the blade is blade is not 90

0

square with the mitre table

adjustment is required.

• Loosen the Bevel Lock Handle and tilt the Cutting Head to

the left.

• Loosen the locknut on the Bevel Angle Adjustment Screw.

(Fig. 14)

• Use a Hex Key to turn the screw in or out to adjust the blade angle.

• Return the Cutting Head to its upright position and recheck

the angular alignment against the Set Square.

• Repeat the above steps until correct angular alignment

is achieved.

• Tighten the Bevel Angle Adjustment locknut securely.

0

0

Bevel Pointer Adjustment

Note: The operator must be satisfied that the blade is set

exactly perpendicular to the table when in the upright position

and against its stop.

• If the pointer is not in exact alignment with the 0

0

mark on

the protractor scale adjustment is necessary.

• Loosen the Bevel Pointer screw using a #2 Phillips

screwdriver. (Fig. 15)

• Adjust the Bevel Pointer so that it is in alignment exactly with

the 0

0

mark.

• Retighten the screw.

Fig. 12

Fig. 13

Fig. 14

Fig. 15

25

www.evolutionpowertools.com

EN

Loading...

Loading...