Maintenance

screwclockwiseorcounterclockwisetoadjustthe

travelofthelever.

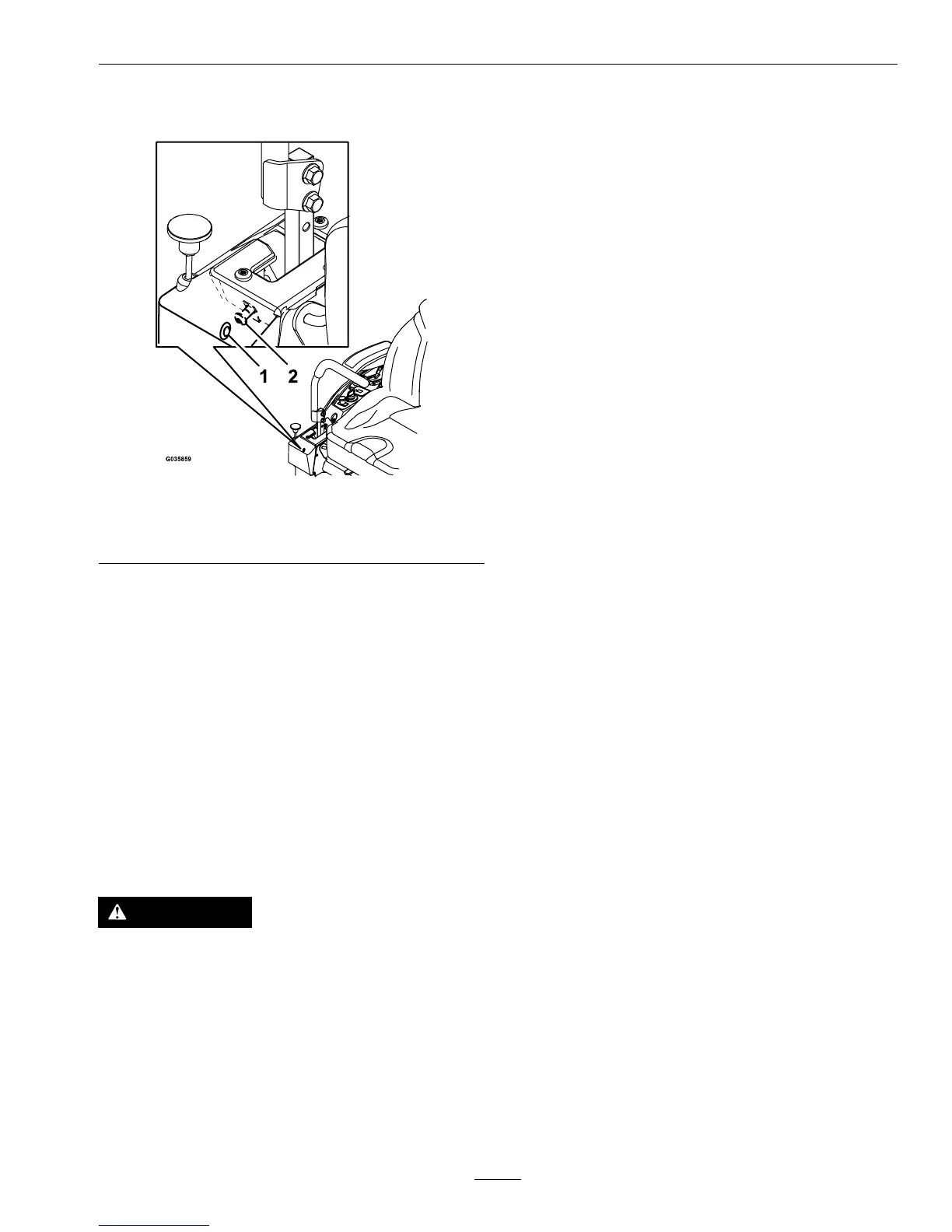

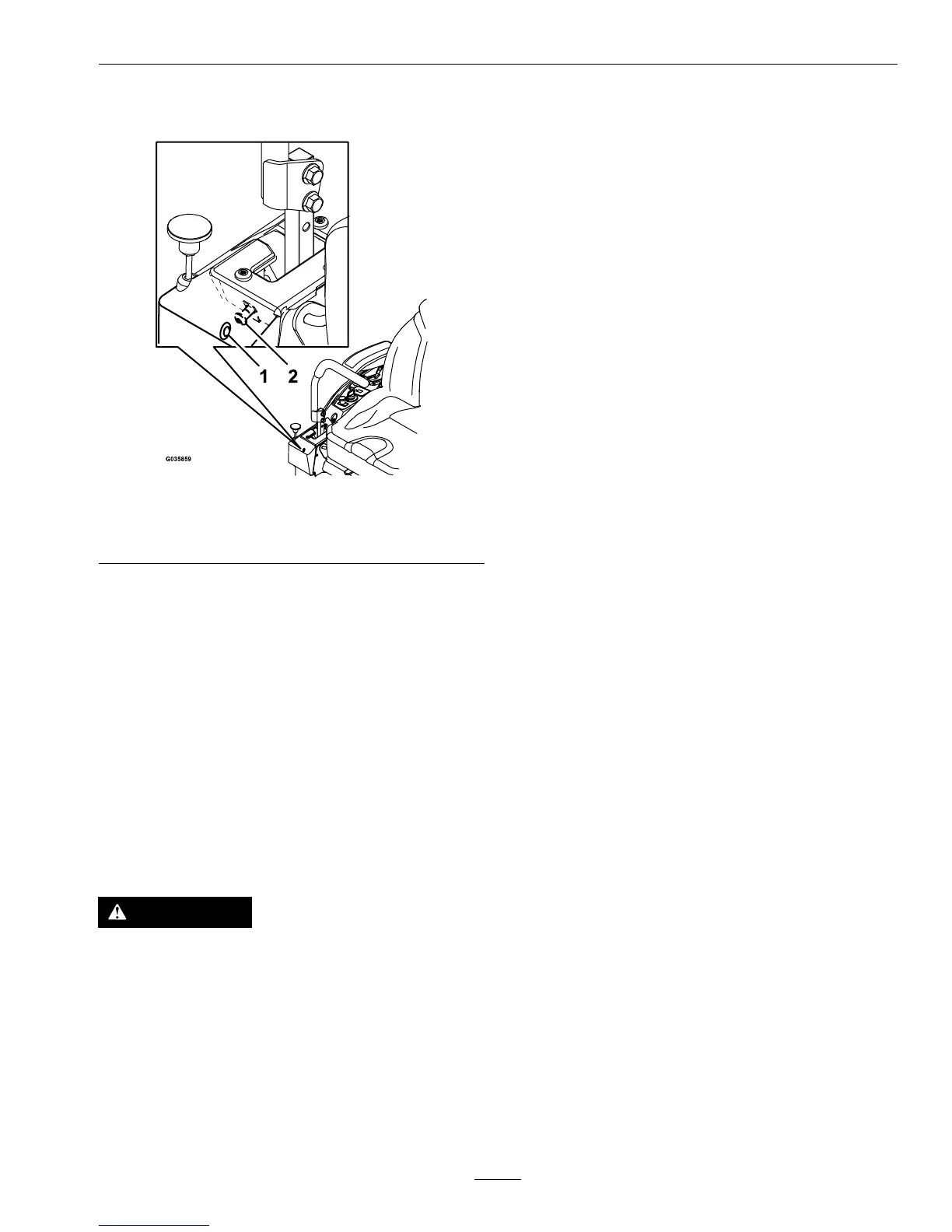

Figure72

1.Accessholeonfront

coverpanel

2.Trackingscrew

2.Drivethemachineandcheckthefullforward

tracking.

3.Repeatsteps1and2untildesiredtrackingis

obtained.

MotionControlLinkage

Adjustment

Locatedoneithersideoftheunit,belowtheseatare

thepumpcontrollinkages.Rotatingtheendnutwith

a1/2inchdeepsocketwrenchallowsnetuning

adjustmentssothatthemachinedoesnotmovein

neutral.Anyadjustmentsshouldbemadeforneutral

positioningonly.

WARNING

Enginemustberunninganddrivewheelsmust

beturningsoadjustmentscanbeperformed.

Contactwithmovingpartsorhotsurfacesmay

causepersonalinjury.

Keepngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

1.Priortostartingtheengine,pushthedecklift

pedalandremovetheheightofcutpin.Lower

decktotheground.

2.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

3.Removetheelectricalconnectionfromtheseat

safetyswitch,locatedunderthebottomcushion

oftheseat.Theswitchisapartoftheseat

assembly.

4.Temporarilyinstallajumperwireacrossthe

terminalsintheconnectorofthemainwiring

harness.

5.Startengine.Brakemustbeengagedand

motioncontrolleversouttostartengine.

Operatordoesnothavetobeintheseat.Run

engineatfullthrottleandreleasebrake.

6.Runtheunitatleast5minuteswiththedrive

leversatfullforwardspeedtobringhydraulicoil

uptooperatingtemperature.

Note:Themotioncontrolleverneedstobein

neutralwhilemakinganynecessaryadjustments.

7.Bringthemotioncontrolleversintotheneutral

position.Thecontrolplatetabsshouldtouchthe

returntoneutralplatesonthehydros.Adjust

pumpcontrolrodlengthsbyturningthenutin

theappropriatedirectionuntilthewheelsslightly

creepinreverse(seeFigure73).Movethemotion

controlleverstothereversepositionandwhile

applyingslightpressuretotheleverallowthe

reverseindicatorspringstobringtheleversback

toneutral.Thewheelsmuststopturningor

slightlycreepinreverse.

Themotioncontrolcovermayneedtobe

removedtogainaccess.

67

Loading...

Loading...