Maintenance

Important:Afterallneutraladjustmentshave

beenmade,makesurethedrivewheelshave

equalspeedinthefullforwardandreverse

positions.

TrackingAdjustment

1.Stopengineandwaitforallmovingpartstostop.

2.Checkthedrivetirepressuresandtire

circumferencesasstatedinChecktheTire

PressuressectioninMaintenance.

3.Runtheunitandobservethetrackingonalevel,

smooth,hardsurfacesuchasconcreteorasphalt.

4.Iftheunittrackstoonesideortheother,turnthe

quicktrackknob.Turntheknobrightto“steer”

right,turntheknobleftto“steer”left.

DriveLeverResistance

Adjustment

Relocatingthehydropumpspringstoadifferent

settingwillchangetheresistanceonthedrivelevers.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Raisetheplatform.

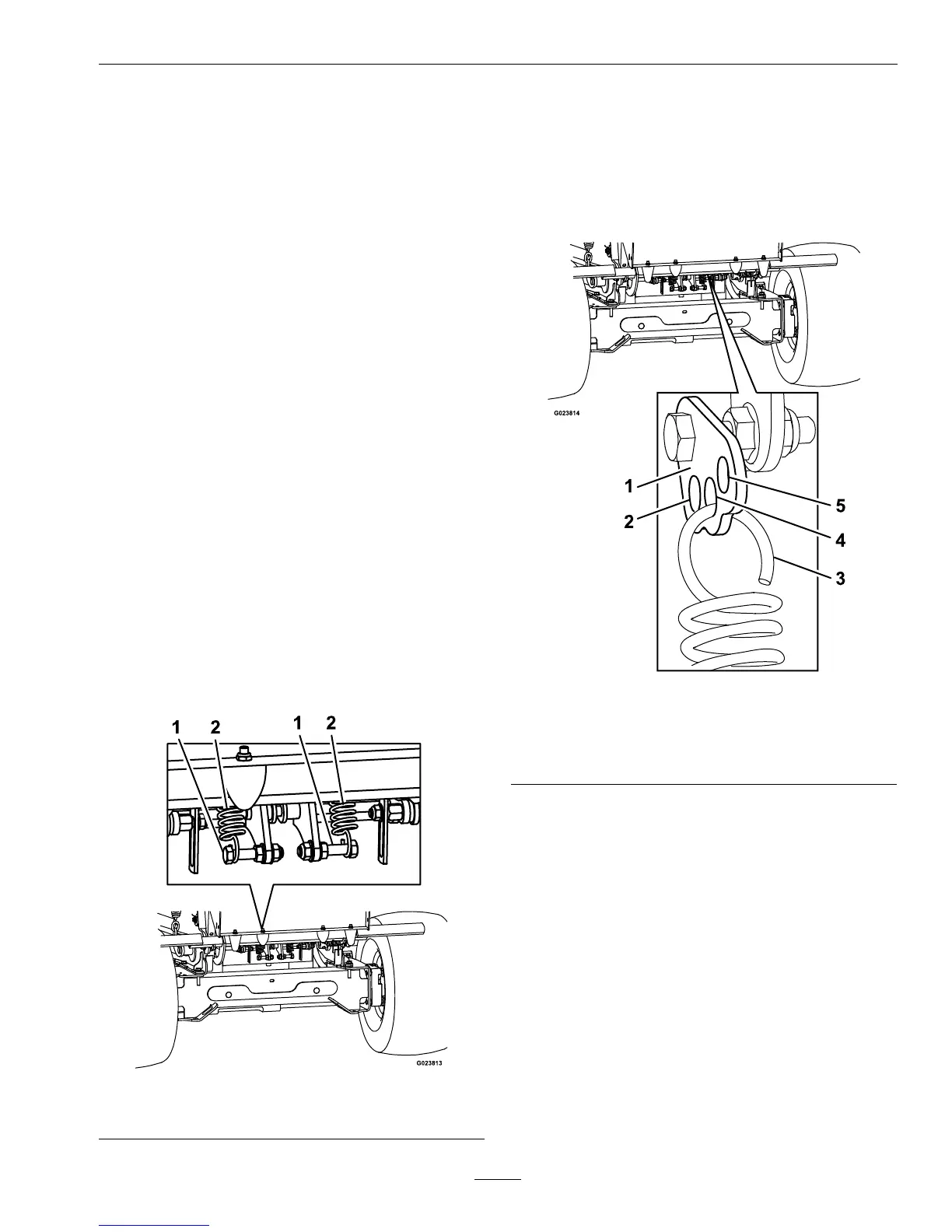

3.Unhookbothspringsfromthelowerbellcrank

bolts(seeFigure38).

Figure38

1.Lowerbellcrankbolt

2.Spring

4.Lowertheplatform.

5.Releasetherearcushionfromtherearofthe

machineandlowertotheplatform.

6.Relocatetheupperspringhooktothepreferred

resistancesettingontheupperadjustablelink;

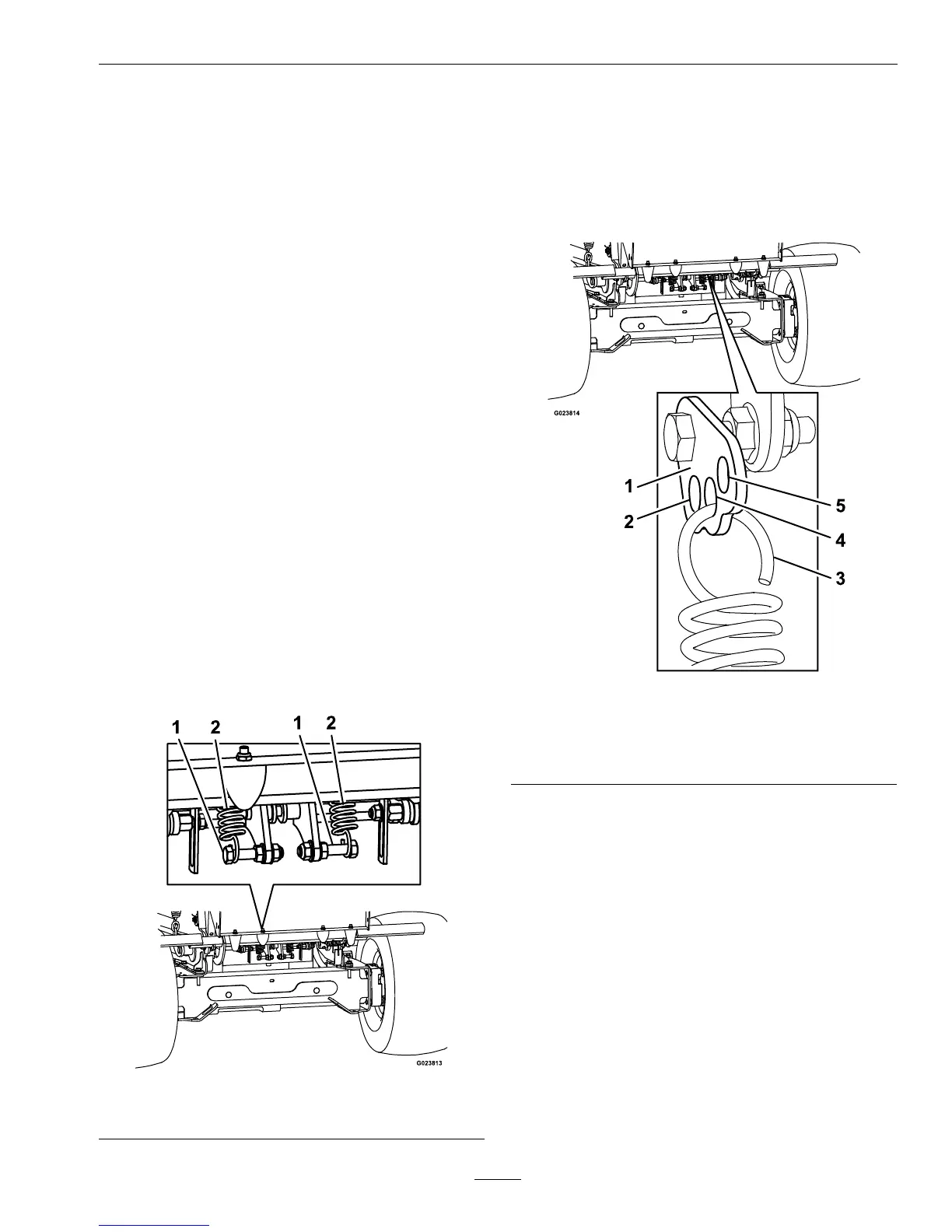

refertoFigure39forsettings.

Figure39

1.RHupperadjustablelink4.Recommendedsetting

2.Higherresistance5.Lowerresistance

3.Upperspringhook

7.Reinstalltherearcushionandraisetheplatform.

8.Reinstallthespringlowerhookontothelower

mountingbolts(referenceFigure38).

9.Lowertheplatform.

10.Starttheengine,releasetheparkingbrake,and

drivethemachine.Iftheunitisslowtorespond

ordoesnotperformonhillsasdesired,relocate

theupperspringhooktoadifferentsetting

(referenceFigure39).

Forheavydutydriveconditions,suchasoperation

onsteepslopes,ahigherspringforcemaybe

requiredtopreventthedrivesystemfromstalling.

Locatetheupperspringhookontothebolt.

Note:Inheavydutyposition,thedrivelever

resistancewillalsobeincreased.

45

Loading...

Loading...