MAX300-RTG : Hardware Manual Hardware Maintenance

61

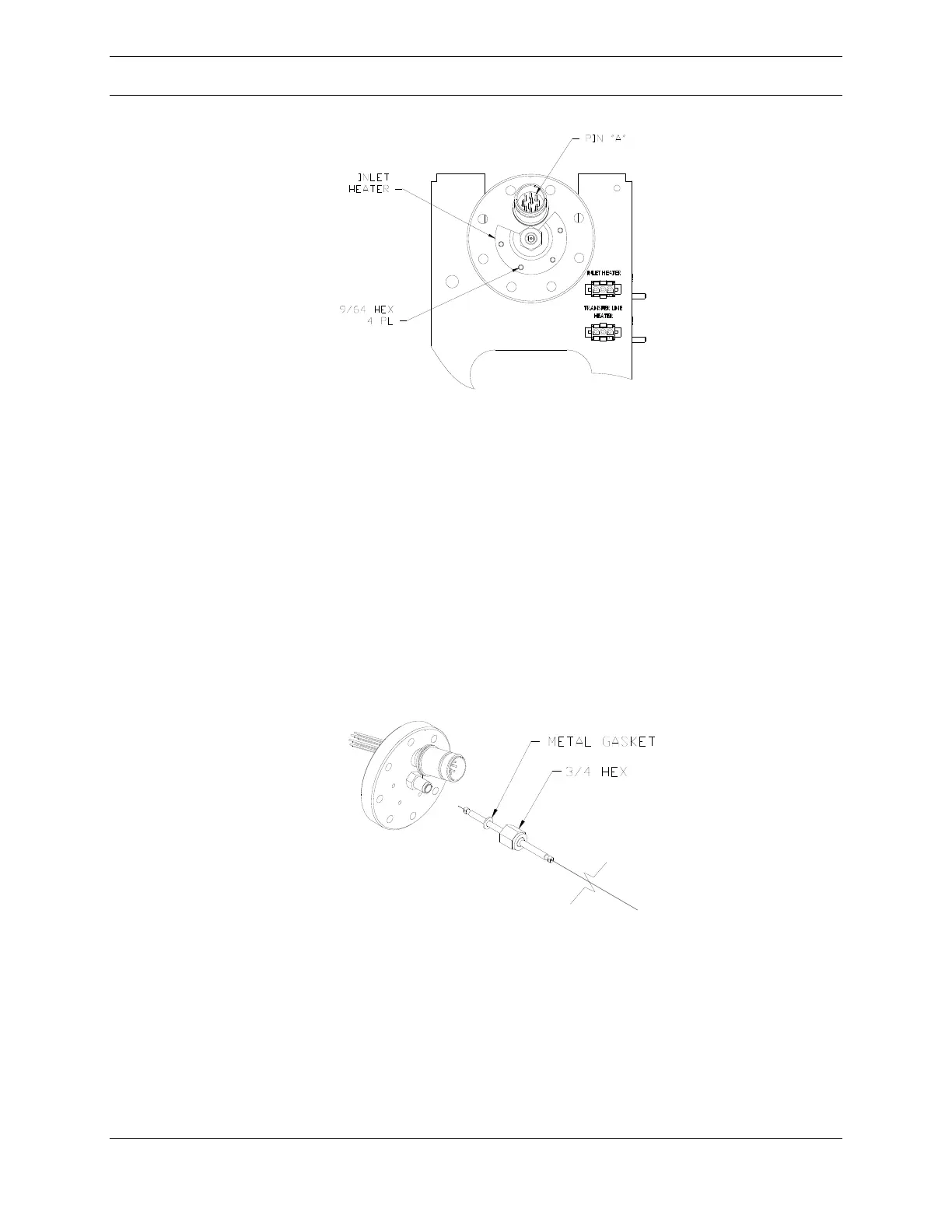

Figure 33: Inlet Mounting

Once the flange has cooled, remove the inlet by loosening the large central fitting

on the ionizer flange. The hex closest to the flange (5/8 inch) is welded on. The

outer hex nut (3/4 inch) can be rotated counterclockwise to loosen the fitting and

remove the inlet. Be careful when loosing this fitting that the wrench does not

contact the ten pin vacuum feedthrough and damage it.

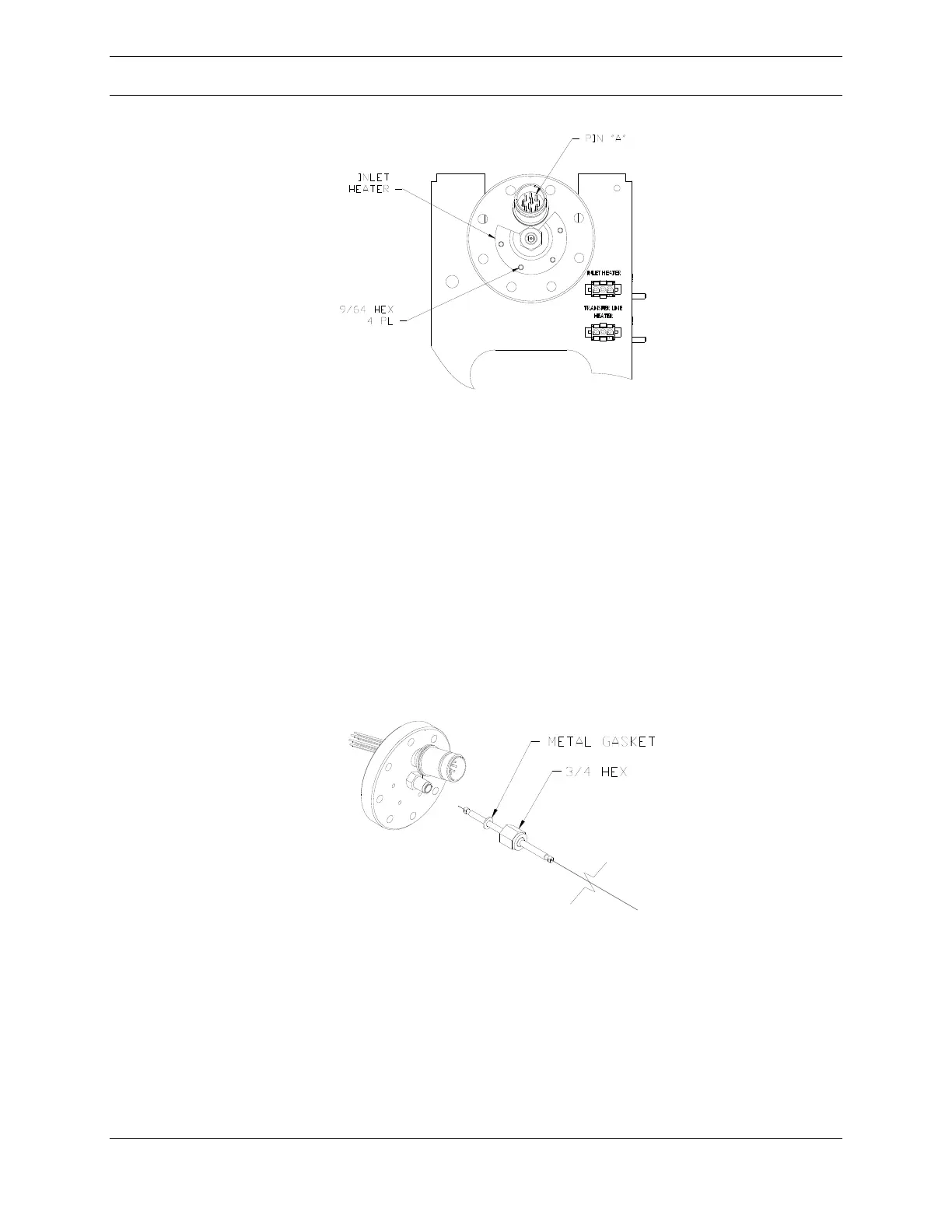

Withdraw the inlet from the flange and remove the non-reusable metal gasket. A

short length of the fused silica restrictor will be visible, as in Figure 34, below. Avoid

clogging or contaminating this critical region.

Figure 34: Inlet

Verify that the replacement inlet has a new metal gasket in place. Slide the end of

the inlet into the flange fitting and tighten the nut ¼ turn past finger tight. Before

finishing the installation of the sample line, check that the new inlet is not touching

the ion region. Use an ohm meter to verify that pin “A” (refer to Figure 41, page 63)

on the ionizer feedthrough is not shorted to ground. Replace the transfer line

heater and thermocouple connectors. Reinstall the inlet heater onto the ionizer

Loading...

Loading...