MAX300-RTG : Hardware Manual Hardware Maintenance

76

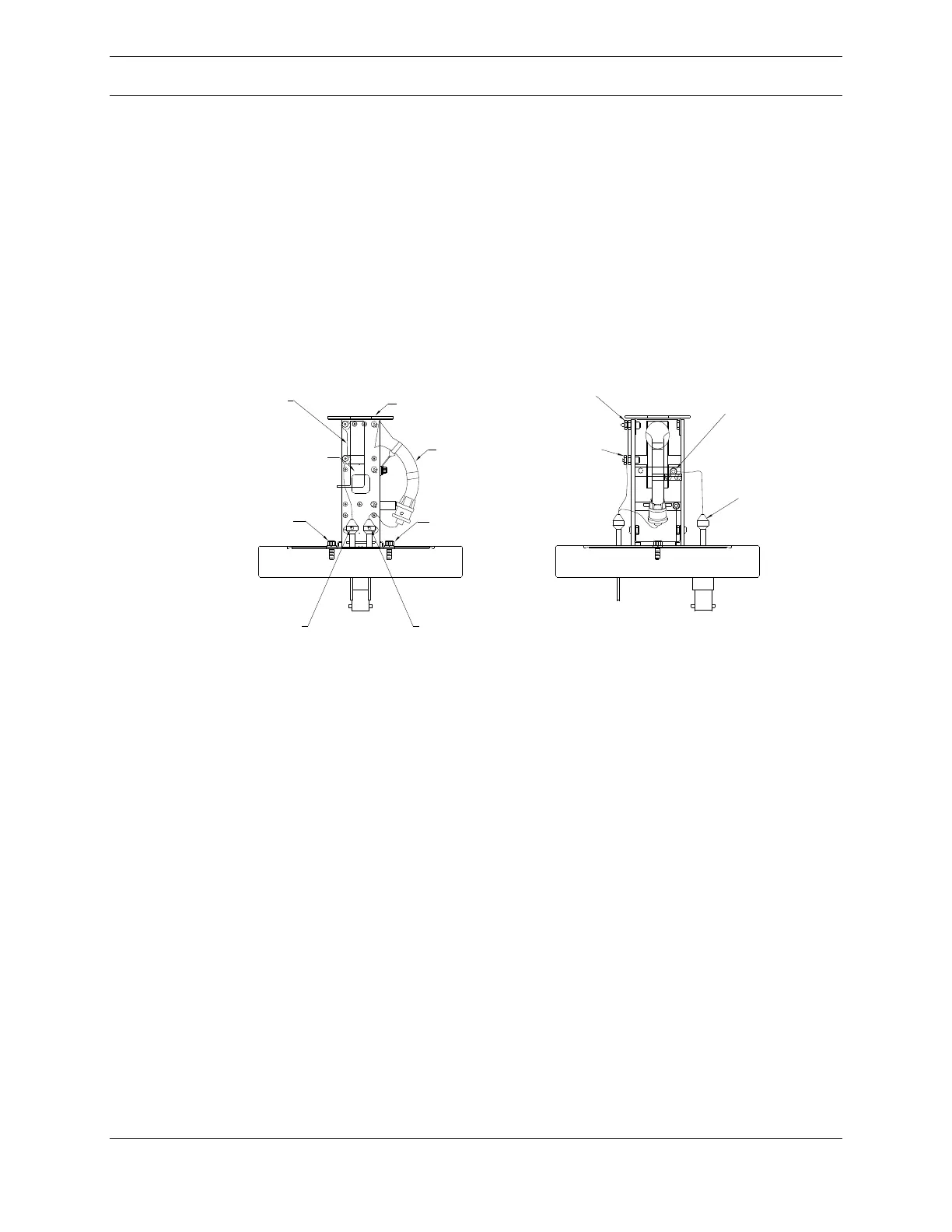

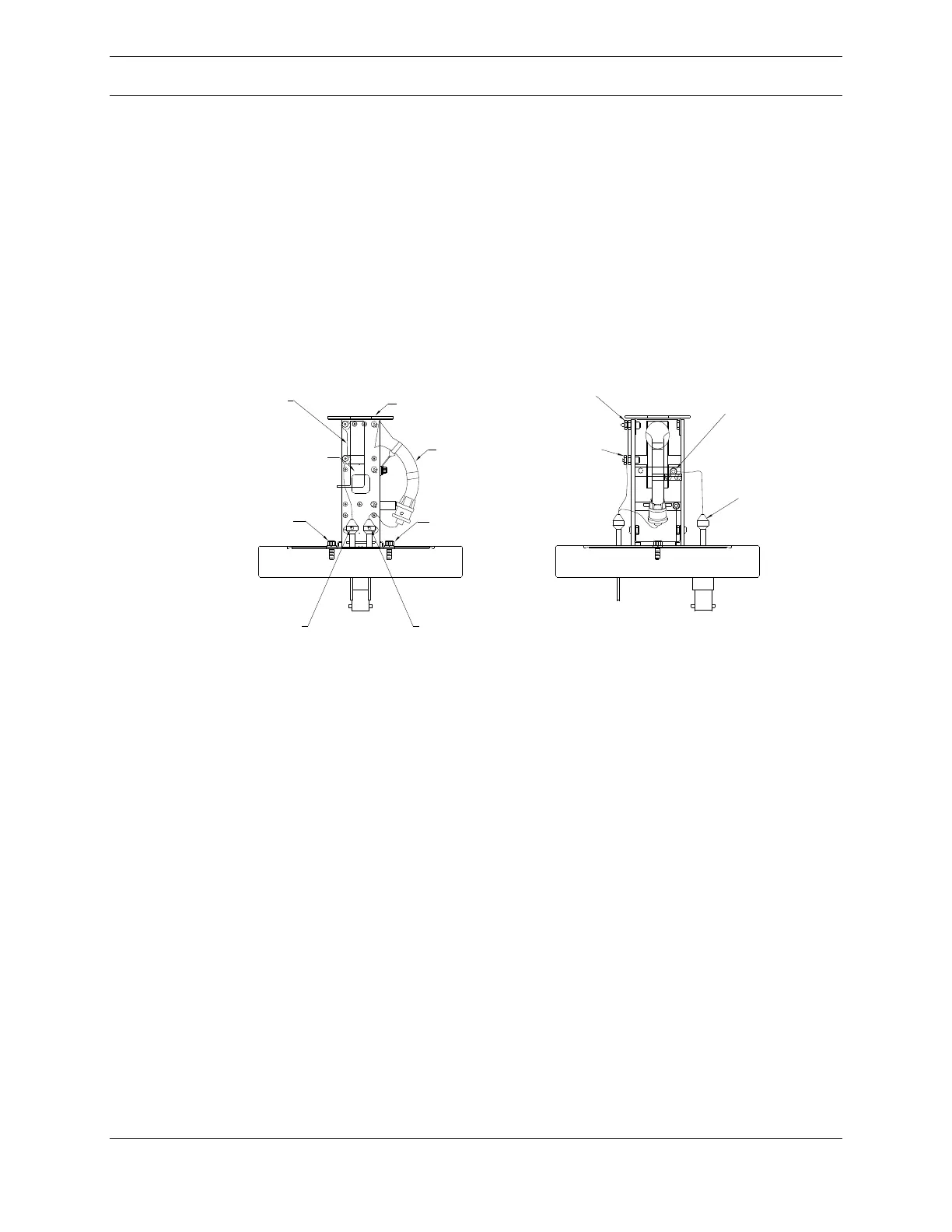

The electrical connections can be pulled straight off the flange feedthroughs. The

multiplier is held to the flange with two 4-40 screws that can be removed with a

3/32inch hex key.

Install the new multiplier onto the flange in the same orientation as the old one

using the 4-40 screws and connect the wires to the flange feedthroughs by pushing

the connectors straight on. Refer to Figure 50, below, to verify that the wiring is

correct.

Faraday Connection

Signal Connection

4-40 Securing

Screw

Shorting Strap

FP & CD

High Voltage

Connector

Multiplier

4-40 Securing

Screw

Multiplier Tube

Faraday Plate (FP)

Conversion Dynode

(CD)

FP Connection

Point

CD Connection

Point

Multiplier HV

Connection Point

* Assembly Rotated 90 degrees

* Assembly Reference Illustration

Figure 6.13.2 Multiplier Assembly Detail

Figure 50: Multiplier Flange

Install the detector flange onto the vacuum chamber using a new 4-1/2inch copper

gasket in the same orientation it was originally. There are two threaded holes on

the flange that can be used to hold the copper gasket in place. Initially tighten the

bolts finger tight. Use an ohm meter to verify that each of the three detector

electrical leads is isolated from each other, from ground and from the quadrupole.

Note: It is normal for the high voltage connection to show 80 Megohms when

measured to ground.

Once verified that the wiring is correct, tighten the flange bolts a little at a time in a

cross pattern to keep the flanges parallel, prevent leaks, and keep the copper

gasket from becoming warped. Start the turbo and roughing pump. When both are

working correctly, attach the preamp to the flange and re-install the preamp and

multiplier HV cables.

Loading...

Loading...