Page 6 of 50

CNC 8055 / CNC 8055i

Improvements to

the profile editor

N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

10 Improvements to the profile editor

The following improvements have been made:

It is possible to select the coordinate system of the work plane, axes

and their direction.

The right window, under "Display Area", indicates whether the

autozoom is on or not and the selected coordinate system.

It includes graphic data editing. Use the up-arrow and down-arrow

keys to select the desired window and key in the desired value.

It is possible to modify rectangular and circular elements.

There are 2 new softkeys:

Save and continue

To save a profile without having to quit the session.

Undo

To undo the last modification.

On conversational models, MC and MCO, it indicates the number of

the profile being edited.

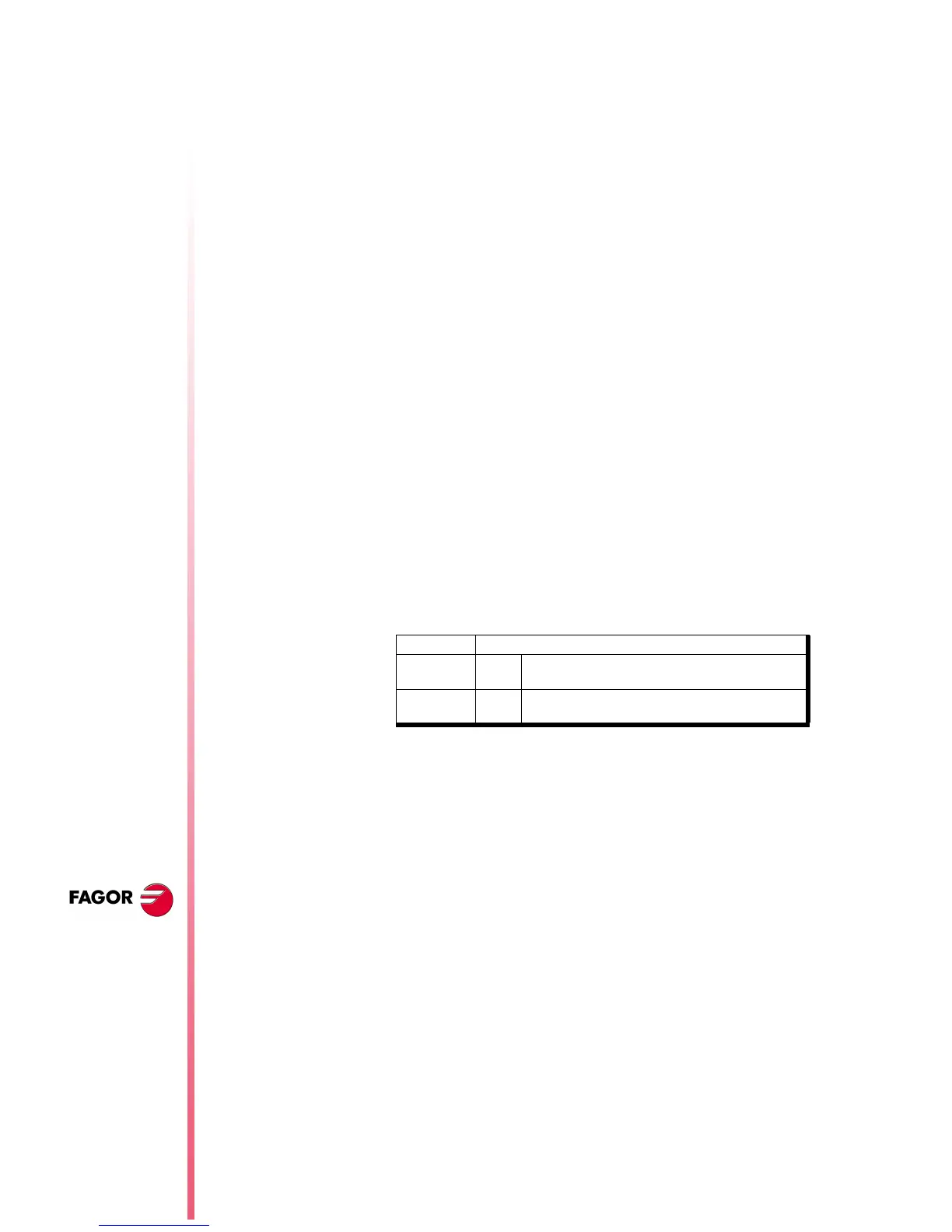

11 Modified variables

HARCON

It indicates, with bits, the CNC's hardware configuration.

The bit will be "1" when the relevant configuration is available.

From now on, bits 24, 25, 26 indicate the type of monitor and bits 27,

28 the CPU turbo board being used.

MPGn

MP(X-C)n

MPSn

MPSSn

MPASn

MPLCn

These variables, related to machine parameters, that until now were

read-only, from this version on, can be read and written from the

CNC in the following cases:

•

When they are executed inside an OEM program.

•

When they are executed inside an OEM subroutine.

To modify machine parameters from the PLC, an OEM subroutine

containing the relevant variables must be executed using the

CNCEX instruction.

In order for the CNC to assume the new values, one must operate

according to the indicators associated with each machine

parameter.

bit

26,25,24 000

001

Color LCD Monitor

Monochrome LCD monitor

28,27 00

01

Turbo board at 25 Mhz

Turbo board at 40 Mhz

// It is necessary to press the keystroke sequence: "Shift -

Reset" or turn the CNC off and back on.

/ Just press Reset.

The rest of the parameters (those unmarked) will be updated

automatically, only by changing them.

Loading...

Loading...