Page 4 of 50

CNC 8055 / CNC 8055i

WINDNC

improvements

N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

8 WINDNC improvements

From this CNC version on and having WINDNC version V2.0 and the

following, it is possible:

•

Select the work unit for CNC files Option (a).

Then indicate the desired work unit: Memory (b), Hard Disk (c) or

Card A (d).

•

From a PC, using the WINDNC application, copy from the CNC

to the PC or vice versa, any file, program or table available in the

CARDA or hard disk. The available new tables are:

These tables are compatible with the tables that have been

saved from the drive to a PC via serial line using WINDDS.

•

Consult the table directory (machine parameters, zero offsets,

magazine, tools, tool offsets, geometry, user parameter, OEM

parameter, etc.).

•

Read global and local arithmetic parameters individually using

variables GUPn and LUP(a,b).

The installation and programming manuals describe how to use

these variables.

•

Having telediagnosis, display CNC screens at the PC in remote

mode via serial line or via MODEM.

•

Having telediagnosis, dial the telephone number associated with

the modem at the PC.

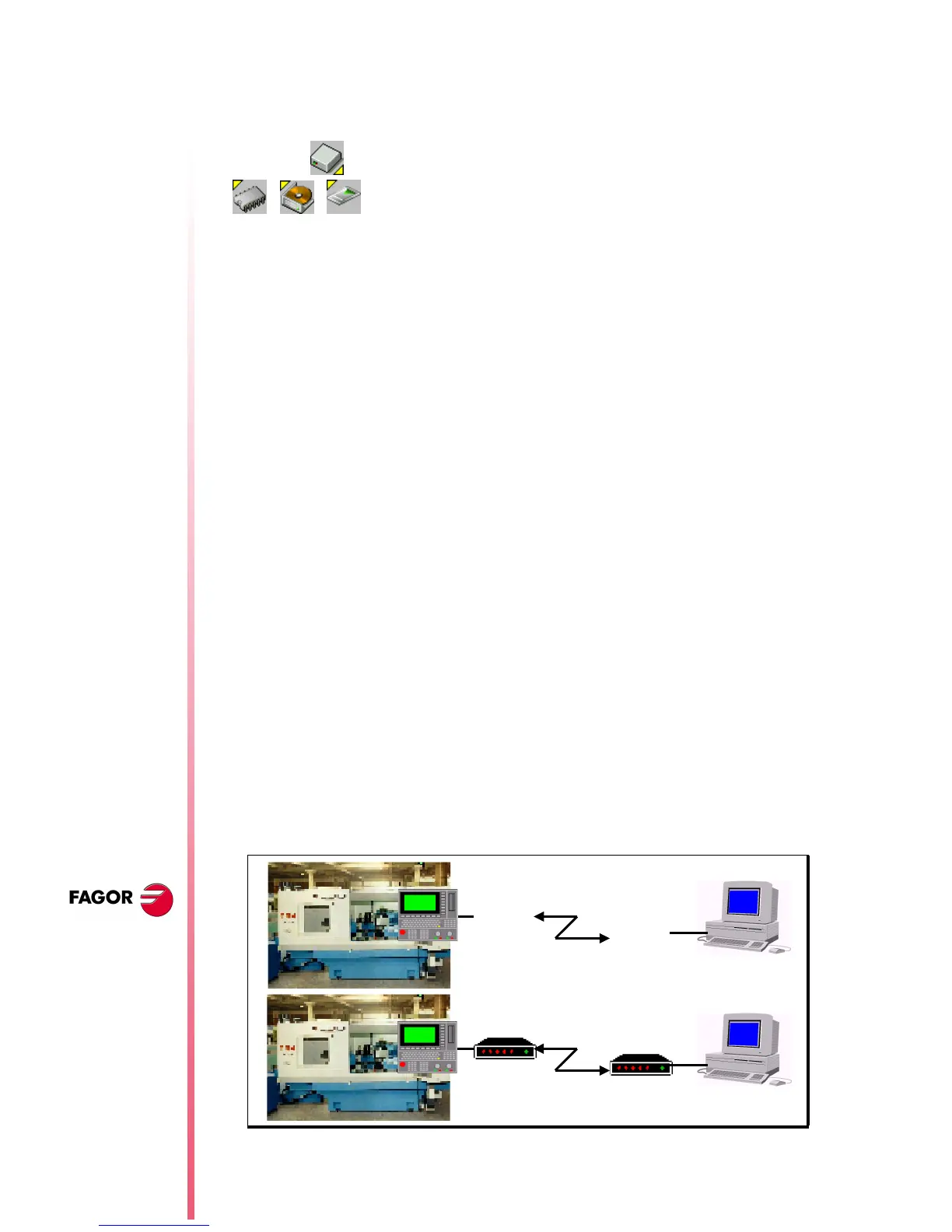

9 Telediagnosis

It may be used to govern and monitor the CNC status remotely

through the RS232 serial line or using a modem through a telephone

line.

OEP OEM arithmetic parameters

USP USER arithmetic parameters

DRS Spindle drive table

DS2 Table of the Second Spindle drive

DPX Table for the Auxiliary spindle drive

DRX, DRY,

DRZ, DRU,

DRV, DRW,

DRA, DRB,

DRC

Tables for axis drives

(b)

(a)

(c)

(d)

CNC PC

(RS232)

Loading...

Loading...