Auxiliary modules

4.

AUXILIARY MODULES

Bus protection module. BPM

200

Ref.1912

DDS

HARDWARE

· 196 ·

4.6 Bus protection module. BPM

Install in DDS systems having:

Synchronous spindle and only when required by the application.

Purpose. Protect the power semi-conductors (IGBTs) of the drive that

governs it, thus preventing damage to the unit due to a very high voltage that

may be generated at the power bus because the braking energy cannot be

returned when a voltage drop occurs.

and/or,

RPS power supply when only the controlled stop is to be ensured.

Purpose. To ensure a controlled stop of the motor due to mains failure

because the energy may be dissipated while braking at the external Ballast

resistors installed in the BPM module. Not installing this module will result in

an uncontrolled stop (by friction) in case of a voltage failure due to an over-

voltage error of the bus because there are no resistors to dissipate the

braking energy.

Outside look

Technical data

F. H4/11

Bus Protection Module, BPM. Outside look.

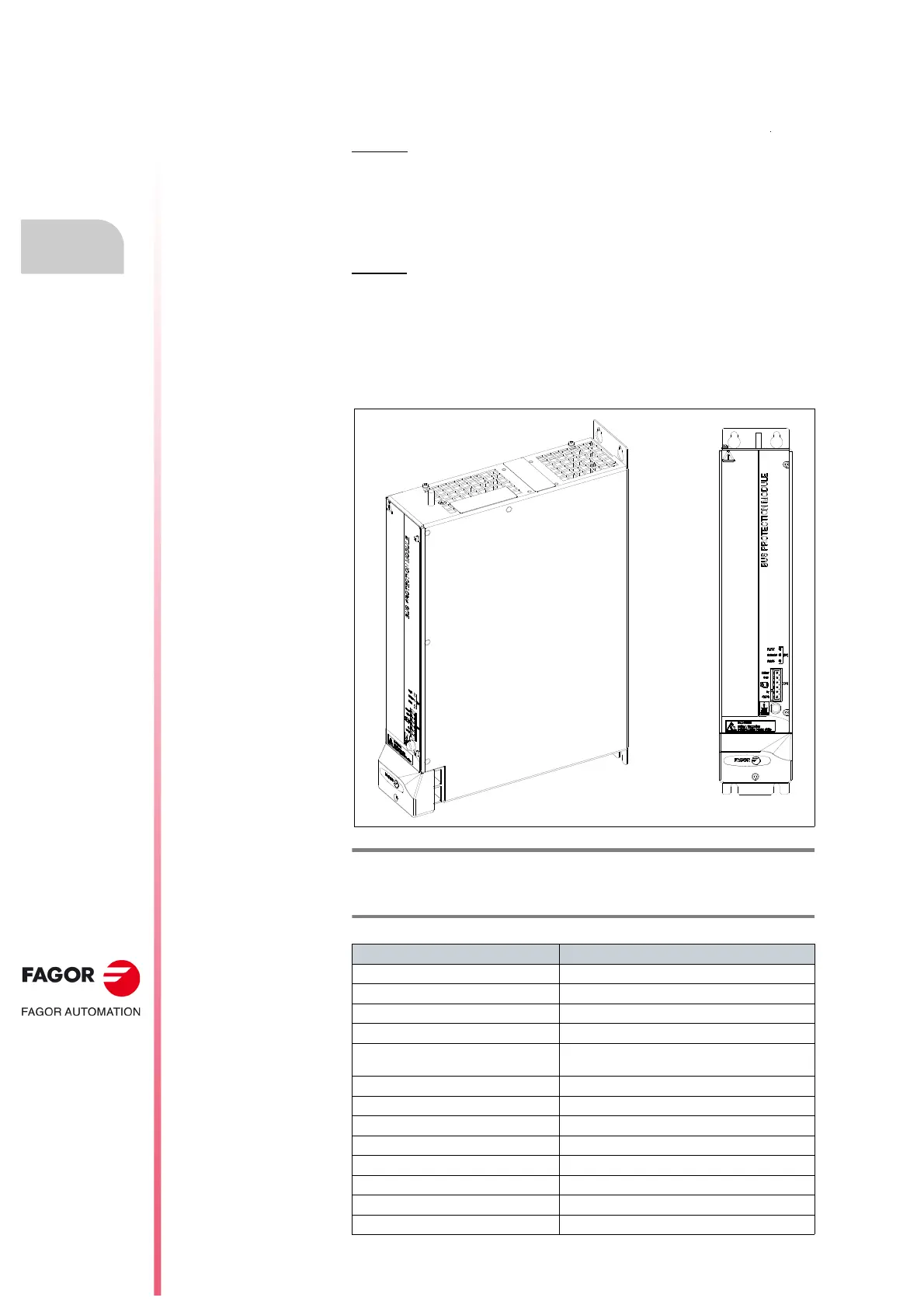

T. H4/13 Bus Protection Module, BPM. Technical data.

Bus Protection Module BPM

Power voltage input 542-800 V DC

Control circuit voltage 24 V DC (between 22-26 V DC)

Control circuit consumption 0.1 A

Protections Short-circuit, over-temperature

Ballast resistors

≥ 18 Ω. Up to three 18 Ω resistors

may be connected without power limit

Maximum braking power 100 kW

Filter capacity 410 µF, 900 V DC

Max. voltage at DR OK contact 125 V AC, 150 V DC

Max. current at DR OK contact 1 A

Approx. mass kg/lb 3.6/7.9

Ambient temperature 0°C/45°C (32°F/113°F)

Storage temperature -25°C/60°C (-13°F/140°F)

Maximum humidity

< 90 % (non condensing at 45°C/113°F)

Loading...

Loading...