Connection diagrams

10.

Ref.1912

· 353 ·

DDS

HARDWARE

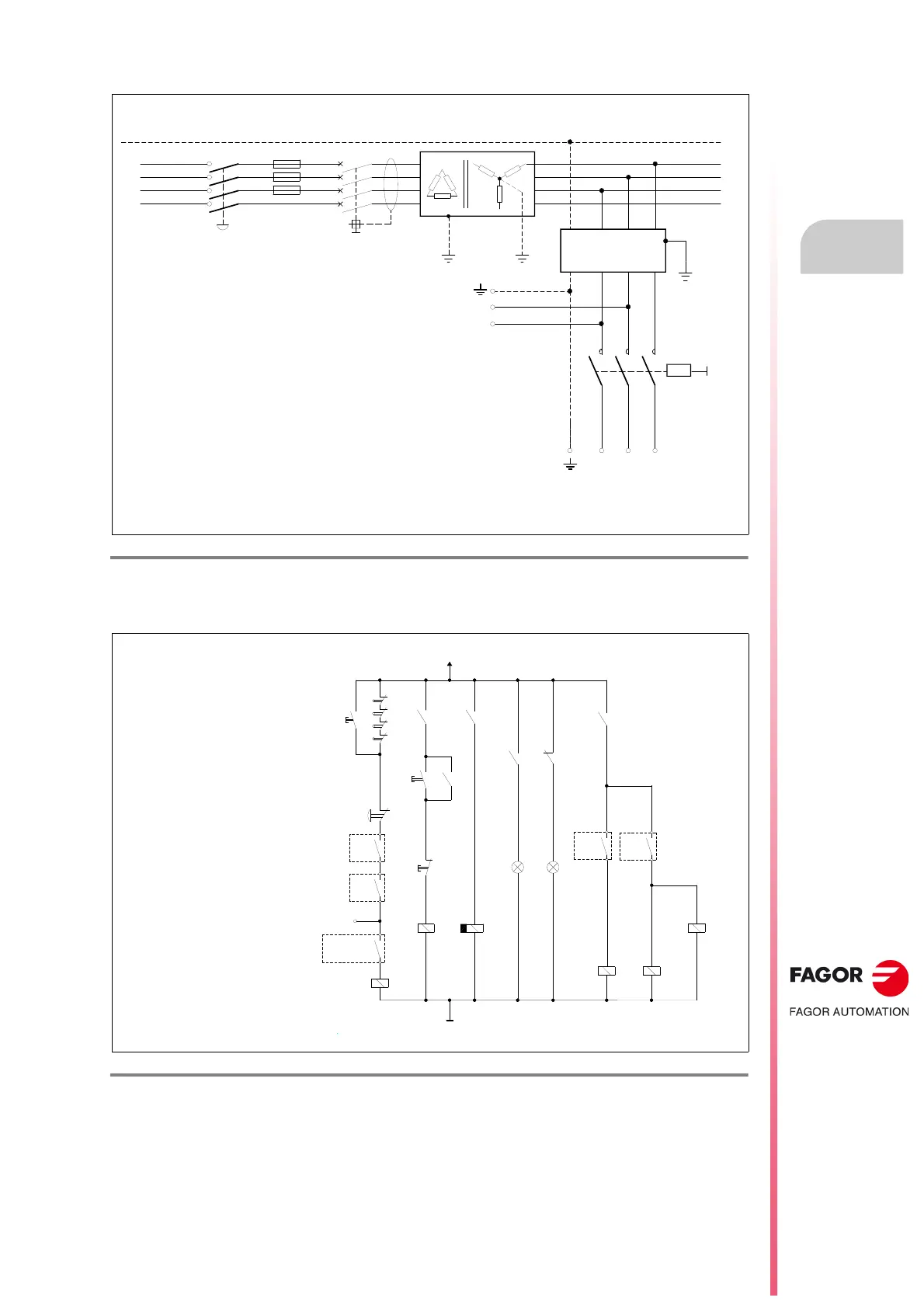

Diagram for general connection to mains

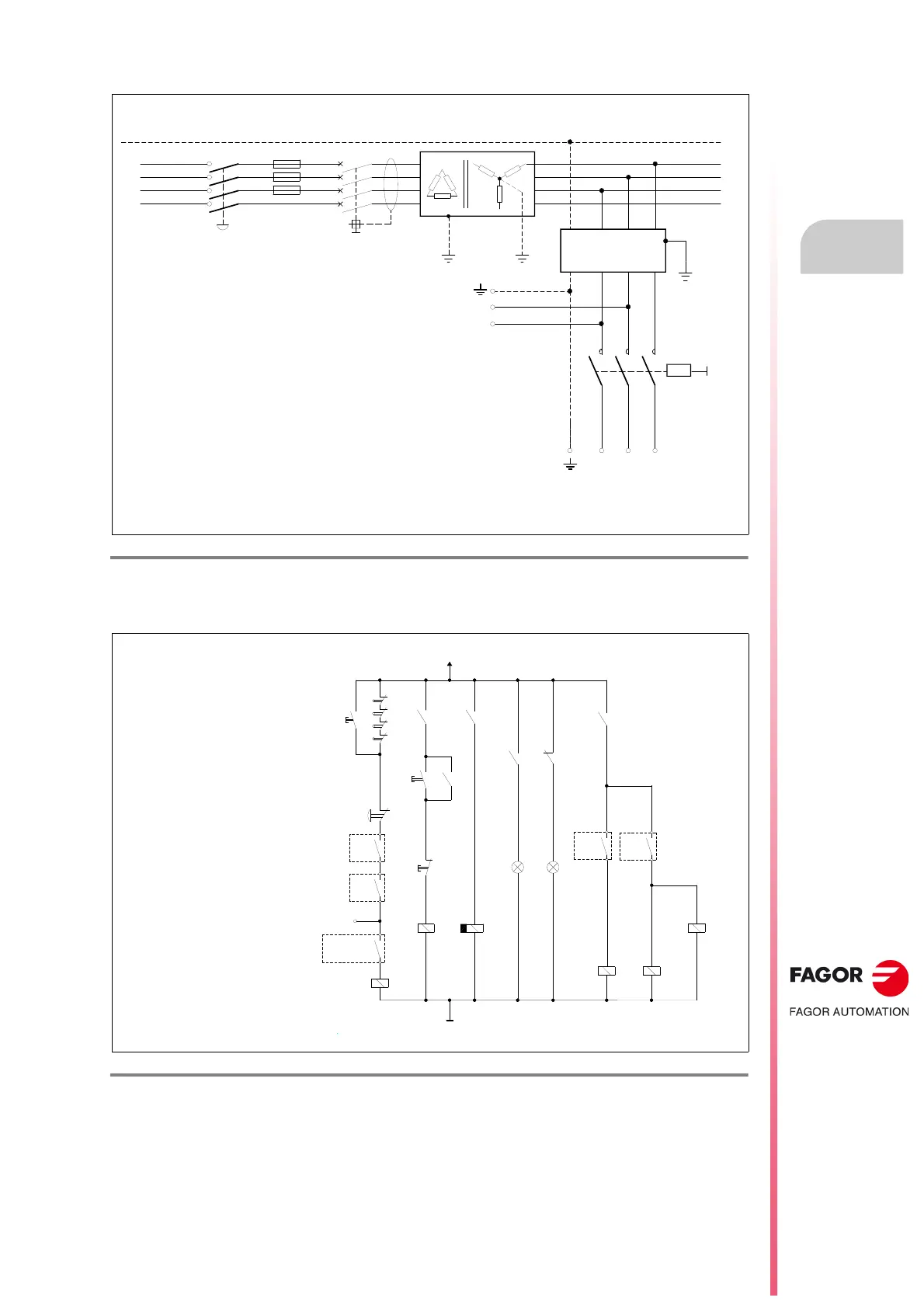

Diagram of the maneuver

F. H10/2 6

ACD/SCD compact drive, CAN. Diagram for general connection to mains.

F. H10/2 7

Compact DDS system. ACD/SCD, CAN. Diagram of the maneuver.

PE

- S1

MECHANICAL

MAIN SWITCH

- F3

- F4

- F5

MAIN FILTER 42A-A

L1

L1L2L3

3x 400-460 VAC

2x 400-460 VAC

L1

L2

L3

CONTACTOR

- KM1

L2

N

- Q1

DIFFERENTIAL

BREAKER

WARNING. When using an isolating transformer, the secondary must be

connected in star and its middle point must be connected to GND.

POWER MAINS

IT A MUST TO USE FUSES

TO THE X1

CONNECTOR

TO THE POWER CONNECTOR

ACD/SCD COMPACT DRIVES

L1

L2

L3

Note.

Observe that having the main key -S1 closed, although the power

contactor - KM1 is open, the internal 24 auxiliary power supply of the

unit remains connected through its connector X1 to feed the control

circuits of the drive.

Important.

The relay KA3 uses delayed

deactivation (t seconds)

maintaining the DRIVE ENABLE

control signal active for a few

seconds to maintain motor torque

while the vertical axis holding

brake is enabled.

See parameter GP9 in the

“man_dds_soft.pdf” manual.

Note.

CNC EMERG. will always be

assigned to I1/O1 of the PLC with

an 8055/55i CNC. With an 8070

CNC, it may be assigned to any I/O

of the PLC. The contacts

associated with relays - KA3, - KA4

and - KA6 are shown in fig.

F.

H10/25

and the contactor - KM1 in

fig.

F. H10/26

.

KA3

-KA6

EMERG.

STOP

DR.X

OK

DR.Z

OK

I1 PLC

CNC EMERG.

O1 PLC

-KA1

EMERGENCY LINE

GND

ON OFF

TO SPEED ENABLES

-KA4

BRAKE

CONTROL

BRK

(See GP9)

CNC

ENABLE

X

CNC

ENABLE

Z

KM1

KA3

KM1

+24VDC

X+

X-

Z+

Z-

KA1

ON

KM1

OFF

-KM1

DELAY OFF

-KA3

DRIVE

ENABLES

ON

Green

OFF

Red

t seconds

Loading...

Loading...