CQR-34/56 Fagor Compact Drives and Motors Quick Reference. Ref.1910

Electrical characteristics

PRECAUTIONS WHEN INSTALLING THE MOTOR

This section describes the environmental precautions to bear in mind

when installing the motor

.

The motor must be installed under the following conditions:

Leave enough clearance for the cooling fan to blow the air out.

The minimum clearance between the machine and the exit of the

motor fan is 100 mm (3.94 in).

Install the motor in a clean place, away from oil and water. If there

is a chance that the motor may be exposed to oil or water, cover

it for protection. If dirty oil or water gets into the motor, it would

decrease the isolation resistance and cause a grounding failure.

Make sure that the motor is firmly secured to the floor or with the

flange because the weight of the motor the dynamic load when it

is running may generate vibrations.

Install the motor in an environment free of dust and metal

particles. The motor has an integrated fan with an internal

structure that provides cooling air to the motor. Blocking the air

flow with dust other strange elements may decrease the efficiency

of the cooling system.

CONSIDERATIONS FOR MOTOR INSTALLATION

Bear in mind the following considerations when installing the motor:

If it is a flange-mounted motor, it may be installed with its shaft at

the load end and at an angle between the horizontal and vertical

with the shaft facing down.

If it is a foot-mounted motor, it must be mounted with its feet

secured to the floor. If the motor is installed vertically, its shaft

must be facing down.

CAUTION !

Note that when installing transmission pulleys or

gearboxes, any blow to the shaft reduces its useful life, of

bearings, and may damage the encoder.

Therefore, do not hit it for any reason.

RADIAL LOADS

A misalignment between the motor shaft and the machine axis

increases vibration of the shaft and shortens the life of the ball

bearings and couplings. Likewise, exceeding certain maximum radial

load values may cause a similar effect of the ball bearings.

FM7. E01|E02 series

FM7. E03 series

FM7. HS3 series

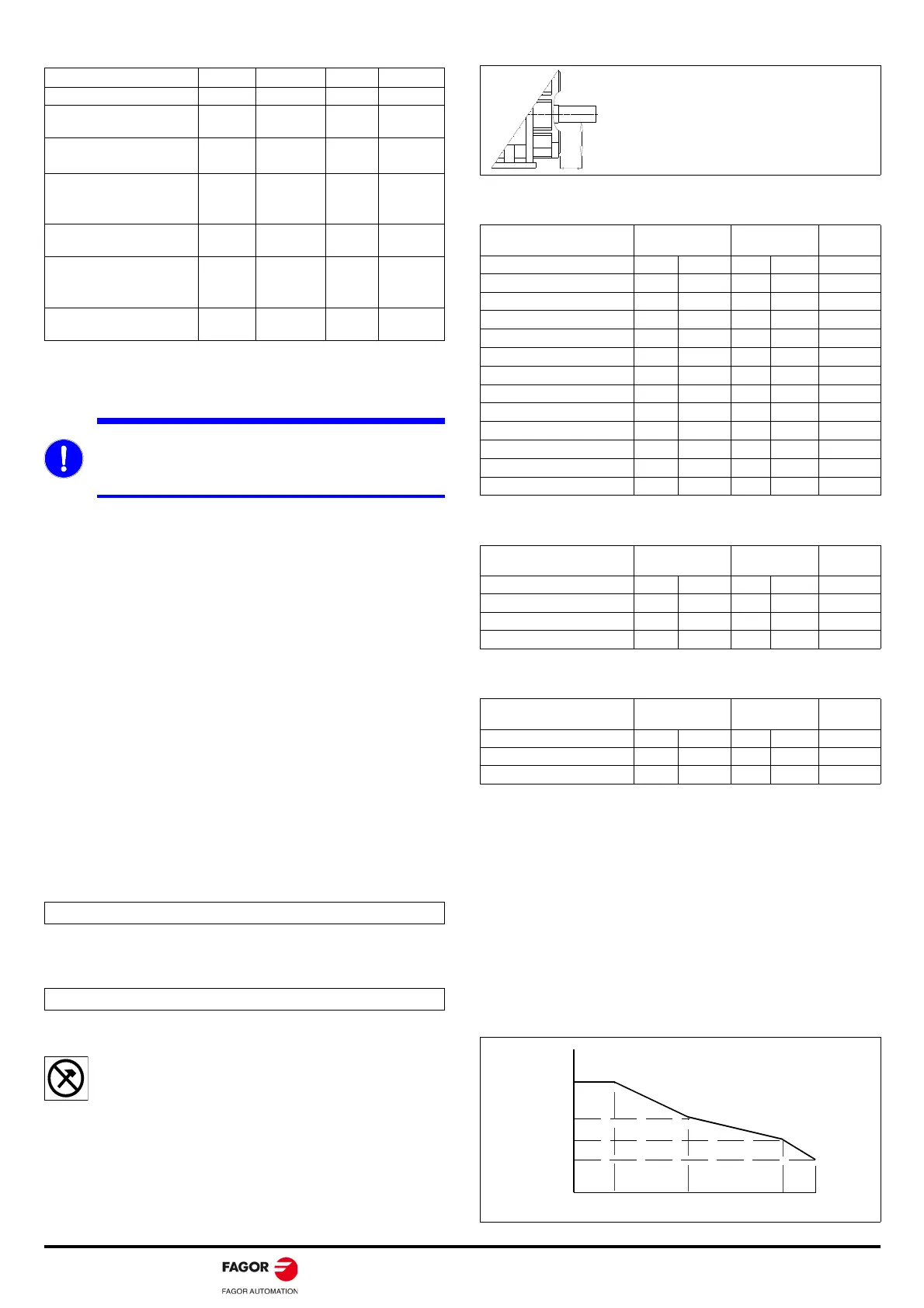

GRAPHS-RPM

When using mechanical transmission elements, the end of the motor

shaft may be subjet to radial loads.

Make sure that the maximum radial load values at the end of the

shaft do not exceed the permitted values shown on the graphs

depending on the rev/min of the shaft.

Exceeding these radial load values increases the vibration of the

shaft and shortens the life of the ball bearings and couplings.

The particular graph may be used to determine the permitted radial

loads that may be applied on to the end of the motor shaft depending

o its rev/min.

Motor Voltage Frequency Power Current

Units V AC Hz W A

FM7-A037--E0

400

460

50/60

60

37/51

60

0.11/0.14

0.16

FM7-A055--E0

FM7-D055-S1D0-E03

400

460

50/60

60

64/85

96

0.11/0.16

0.17

FM7-A075--E0

FM7-D075-S1D0-E03

FM7-D075-S1D0-HS3

400

460

50/60

60

41/62

63

0.07/0.10

0.09

FM7-A090--E0

400

460

50/60

60

45/58

63

0.11/0.10

0.10

FM7-A110--E0

FM7-D110-S1D0-E03

FM7-D110-S1D0-HS3

400

460

50/60

60

59/83

88

0.11/0.14

0.13

FM7-A150--E0

400

460

50/60

60

59/83

88

0.11/0.14

0.13

MANDATORY. The flange and the shaft of the motor have

an anticorrosive layer of paint or grease. The flange, the

shaft and the key must be cleaned before installing the

motor.

Note. The motor must not be mounted with its shaft facing up.

Note. The motor must not be mounted with its shaft facing up.

Motor Radial force

·Fr·

Distance

·d·

Units N lb mm in

FM7-A037--E01

1370 308.0 60 2.36

FM7-A037--E02

1140 256.3

60 2.36

FM7-A055--E01

1570 353.0

80 3.15

FM7-A055--E02

1510 339.5

80 3.15

FM7-A075--E01

1570 353.0

110 4.33

FM7-A075--E02

1510 339.5

110 4.33

FM7-A090--E01

1570 353.0

110 4.33

FM7-A090--E02

1470 330.5

110 4.33

FM7-A110--E01

1715 385.5

110 4.33

FM7-A110--E02

1590 357.4

110 4.33

FM7-A150--E01

2640 593.5

110 4.33

FM7-A150--E02

1715 385.5

110 4.33

Motor Radial force

·Fr·

Distance

·d·

Units N lb mm in

FM7-D055-S1D0-E03

196 44.1 60 2.36

FM7-D075-S1D0-E03

196 44.1 60 2.36

FM7-D110-S1D0-E03

290 65.2 80 3.15

Motor Radial force

·Fr·

Distance

·d·

Units N lb mm in

FM7-D075-S1D0-E03

196 44.1 60 2.36

FM7-D110-S1D0-E03

290 65.2 70 2.75

In order to avoid these problems, the

maximum values given in the table for radial

load must not be exceeded.

They are assumed to be applied at the end

of the shaft and for the maximum motor

speed.

RADIA L LOAD

(N)

Fr 1

Fr 2

Fr 3

Fr 4

N1 N2 N3 N4

SPEED

(1 /min)

Loading...

Loading...