Fagor Compact Drives and Motors Quick Reference. Ref.1910 CQR-51/56

GROUND CONNECTION.

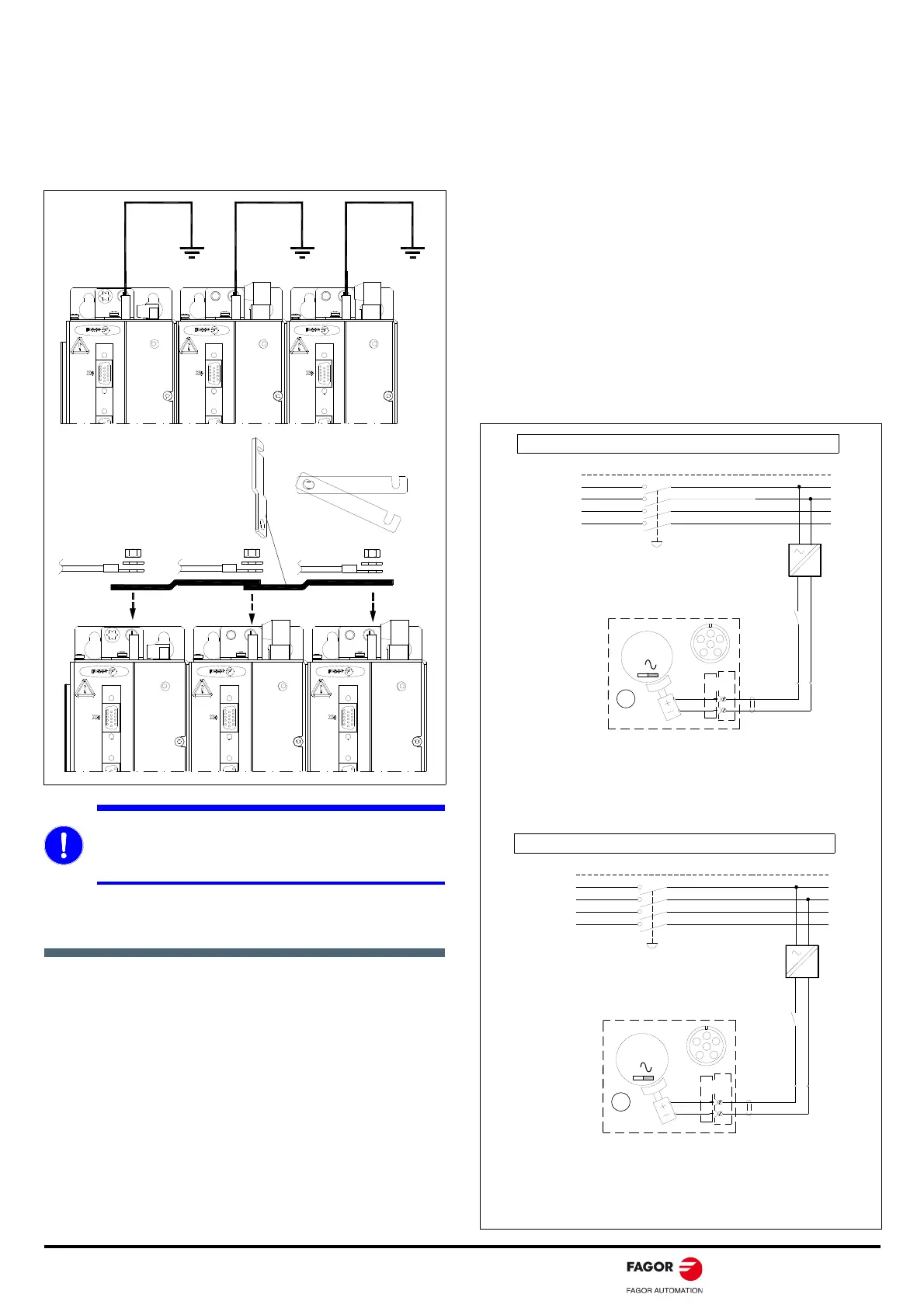

JOINING THE CHASSIS BETWEEN MODULES

The chassis of each module must be connected to the machine

ground point. Use the washers and nuts supplied with each module to

make the ground connection. The tightening torque must be between

2.3 and 2.8 N·m. Connecting these terminals by means of metal

plates offers mechanical ridigity; but it does ot guarantee proper

ground connection of each module.

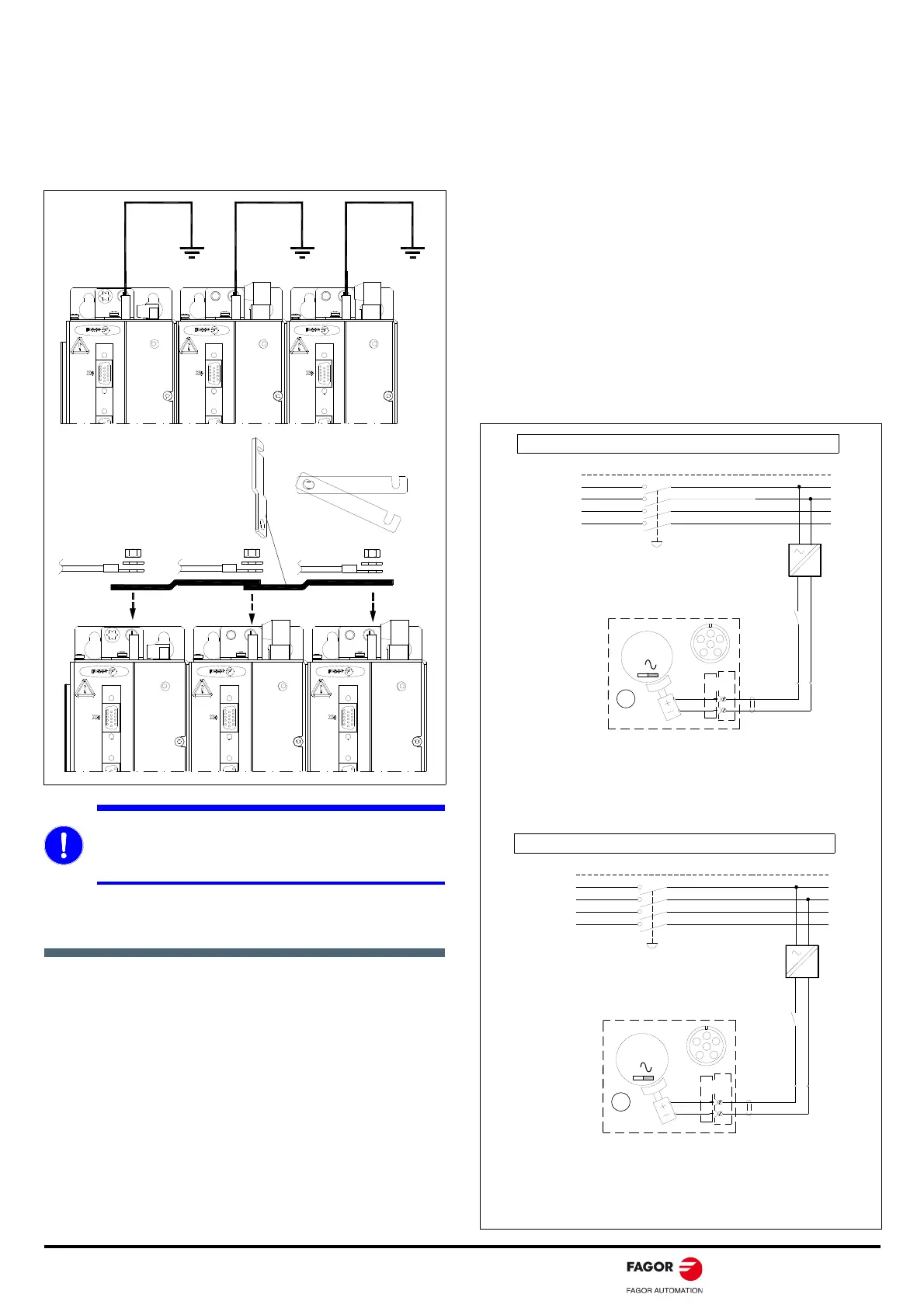

ELECTRICAL DRAWING

The schematics of the following pages are only an orientation to

design the machine and may be expanded or reduced at wil.

Power-up procedure

Supply the compact drives by X1 (L1, L2) (400/460 V AC or

200/240 V AC) from mains. This will supply 24 V DC to the

internal control circuits, and outputs this 24 V DC by X2 (pin 1,

pin 2). Each module runs an internal test. If the test is successful,

the DR. OK contacts close.

Push ON button. This supplies power from mains to the compact

drive modules and activates the DRIVE ENABLE, X2 (pin 4) of

each drive.

Activate the control input SPEED ENABLE, X2 (pin 5) of each

drive from the CNC. The motor can now follow the velocity

command.

Emergency line

The - KA1 relay confirms that the system is mechanically and

electrically in working condition.

Error reset

This circuit configuration joins the error reset and the system power-

up in a single push-button.

Control from CNC

The CNC enables each axis and confirms the SPEED_ENABLE

signal to each drive by means of KA4 and KA6.

Stop

When the emergency line breaks or the OFF or - S1 keys are

opened, the control circuit of the drives must keep on working to

brake the motors, and the DRIVE ENABLE signal must be kept

active (24 V DC). The 24 V DC compact drive output voltage keep

the power to the control circuits, and the DRIVE ENABLE signals are

kept active while braking, by delaying the deactivation of - KA3.

HOLDING BRAKE SUPPLY CIRCUIT

The holding brake of the FKM motors is unlocked by applying +24 V

DC through a connector.

MANDATORY. Take a ground cable (as short as possible)

from each module to each main machine ground point. The

cable section must be the same as that of the cables

connected to the largest servomotor (at least 6 mm²).

PACT DRIVE

PACT DRIVE

PACT DRIVE

PACT DRIVE

PACT DRIVE

PACT DRIVE

FKM MOTOR

BRAKE

4

5

+24 VDC

0 VDC

BR

3

M

Z

4

5

+24 V

=

400 VAC

0 V

IMPORTANT.

Power

the holding brake

with a power supply

that provides

a continuous, stabilized voltage of 24 V DC.

To ensure safe operation in the event of large

temperature variations, the coil must be powered with

stabilized direct current.

PE

3x 400-460 VAC

L1

POWER MAINS

(R)

(S)

(T)

L2

L3

N

- S1

MECHANICAL MAIN SWITCH

FKM MOTOR

BRAKE

4

5

+24 VDC

0 VDC

BR

3

M

Z

4

5

+24 V

=

200 VAC

0 V

IMPORTANT.

Power

the holding brake

with a power supply

that provides

a continuous, stabilized voltage of 24 V DC.

To ensure safe operation in the event of large

temperature variations, the coil must be powered with

stabilized direct current.

PE

3x 200-240 VAC

L1

POWER MAINS

(R)

(S)

(T)

L2

L3

N

- S1

MECHANICAL MAIN SWITCH

Line voltage: 400 (1-10 %) V AC / 460 (1+10 %) V AC

Line voltage: 200 (1-10 %) V AC / 240 (1+10 %) V AC

Loading...

Loading...