CQR-48/56 Fagor Compact Drives and Motors Quick Reference. Ref.1910

MOTOR DRIVE CONNECTIONS

Power connections

Connect the power cable MPC. Connect terminal U of the drive with

the terminal corresponding ti the U phase of the motor. Same as

terminals V-V, W-W, and PE-PE terminal of the drive and NOT to that

of the motor.

Feedback connections

Motor feedback connection

Connect the encoder cable (EEC-SP, EEC-FM7, EEC-FM7S, EEC-

FM7CS), accordingly to take the feedback from the motor to the

drive.

It is connected directly through the feedback cable between the

feedback connector of the motor and connector X4 of the drive

module as long as the isolation level required by FAGOR is

guaranteed between the motor temperature sensor and the power

circuit of the drive.

Note that installing the temperature sensor isolation adapter TSIA-1

means getting galvanic isolation between the temperature sensor of

the motor and the drive itself.

Direct feedback connection or encoder simulator connection

Connect the SEC-HD cable to take the encoder simulation from the

drive to the CNC, or connect the cable to take the feedback from

the sensor to the drive.

CABLING OF THE SYSTEM TO MAINS

Mains connection

The FAGOR DDS compact drive system is designed to be connected

to TN type 3-phase mains with values within the line voltage range

between 400 (1-10 %) V AC and 460 (1+10 %) V AC or 200 (1-10 %)

V AC and 240 (1+10 %) V AC and a line frequency of between 50 (1-

4 %) Hz and 60 (1+3.3 %) Hz.

Certain mandatory protection devices must be added to the mains

lines. Others are optional.

Connecting it to a different voltage range requires the use of

transformers or auto-transformers.

WARNING. FAGOR uses isolation systems between the

temperature sensors and the winding of their motors

ensuring long life to the motor-drive system regardless of

wiring lengths. When installing non-FAGOR motors, since it

cannot be guaranteed that the existing isolation will comply

with FAGOR standards, we recommend installing the

isolation adapter TSIA-1.

INFORMATION. Note that the isolation adapter TSIA-1 does

not check the encoder signals or the temperature sensor of

the motor. It only provides galvanic isolation of the

temperature sensor.

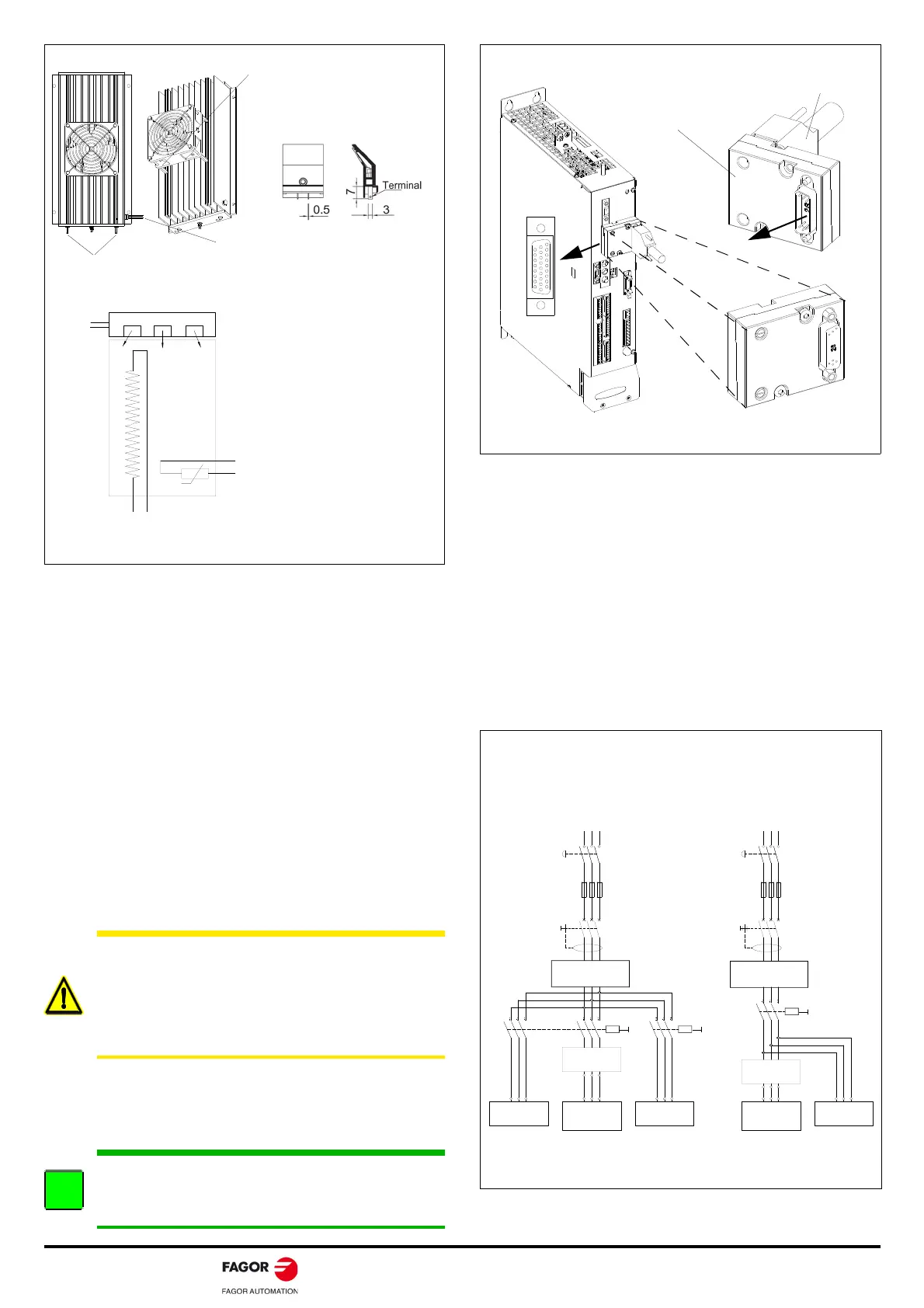

INTERNAL

THERMOSTAT

Tk

Tk

+ 24 V DC

PLC INPUT

160°C

L+

Re

AXIAL FAN

50/60 Hz

220/240 V AC

Always install it vertically

Ballast resistor

connection terminals

Tk connection terminals of the

internal thermostat

DIAGRAM.

Take either one of the two pins to + 24 V DC of the

external power supply of the electrical cabinet

and the other one to a PLC input.

IMPORTANT. Remember to manage the chosen PLC

input in the PLC program to generate an error

when exceeding the limit temperature (160°C)

detected by the sensor and to open the contact.

Take the Ballast resistor terminals to the Re and L+ terminals of the terminal

strip of the Ballast of the power supply.

FASTON type terminals for

connecting the fan

DIMENSIONS of the fan’s

FASTON terminals

Take the fan connection terminals to an outlet of the electrical

cabinet, single phase 50/60 Hz, 220/240 V AC.

Consumption: 0.15/0.13 A, 23/20 W.

Re

L+

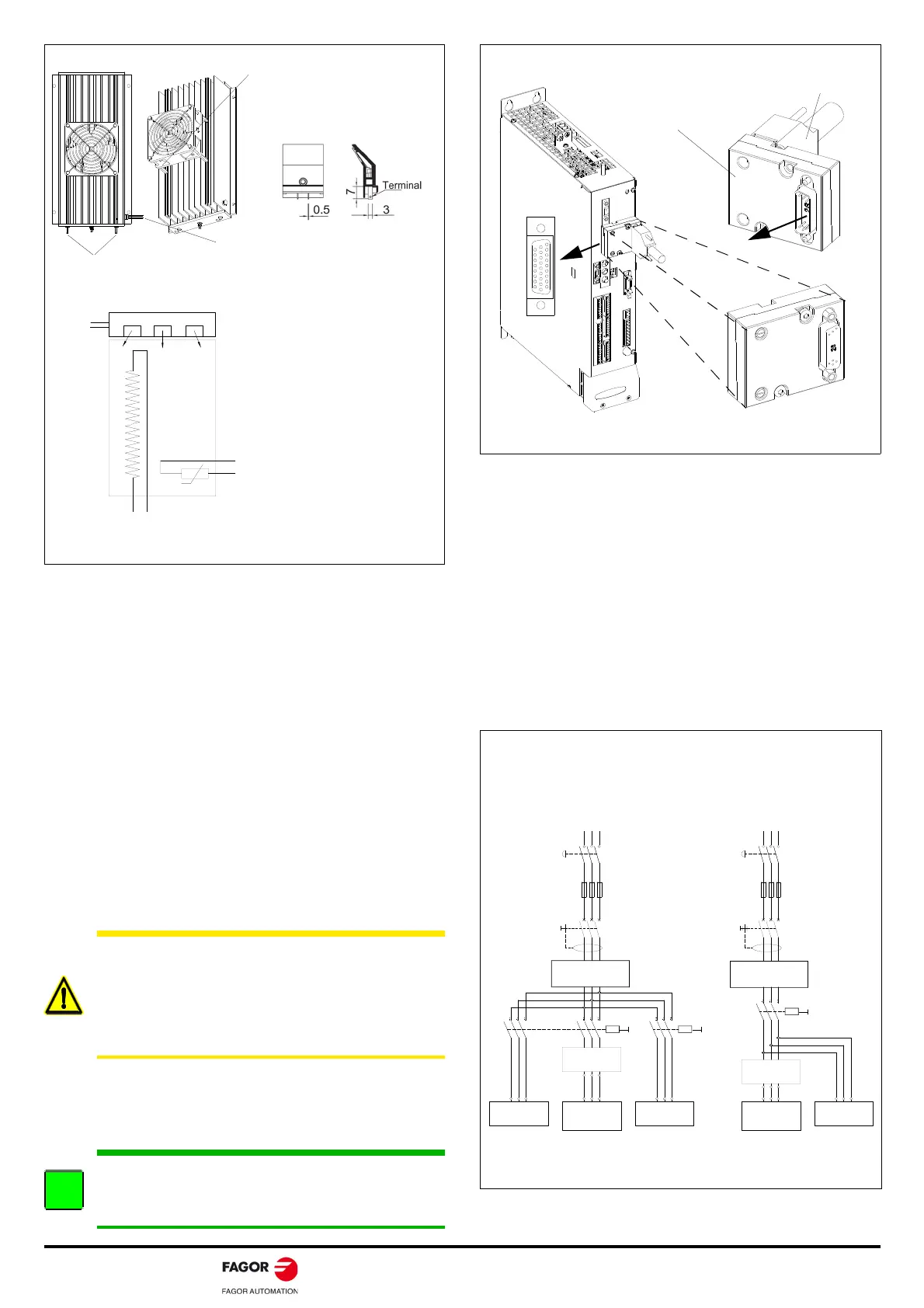

TEMPERATURE SENSOR ISOLATION ADAPTER: TSIA-1

TSIA-1

Front view

ACD/SCD

TSIA-1.

Temperature sensor

isolation adapter

Motor feedback cable

Plug in and tighten the

two screws to connector

X4 of the drive

Note. The pinout of the temperature sensor isolation adapter TSIA-1 is

the same as that of connector X4 of the drive's motor feedback.

TSIA-1

Rear view

- S1

MECHANICAL

MAIN SWITCH

MAIN FILTER

42A-A

L3

L2

L1

(R)

CONTACTOR

- KM1

DIFFERENTIAL

BREAKER

POWER MAINS

IT A MUST TO

USE FUSES

TRANSFORMER oR

AUTOTRANSFORMER

3x 400-460 V AC

ACD/SCD/CMC

OTHER UNITS

- KM2

- Q1

CONTACTOR

OTHER UNITS

CONTACTOR

- KM1

TRANSFORMER oR

AUTOTRANSFORMER

DIFFERENTIAL

BREAKER

- Q1

IT A MUST TO

USE FUSES

- S1

MECHANICAL

MAIN SWITCH

- F

OTHER UNITS

L1 L2

L3

(S) (T) (R)

POWER MAINS

L1 L2

L3

(S) (T)

- F

3x 200-240 V AC

MAIN FILTER

42A-A

oR

L3

L2

L1

3x 400-460 V AC

ACD/SCD/CMC

3x 200-240 V AC

OR

Note. The mains filter may be installed indistinctly before or after the

power switch - KM1.

MAINS CONNECTION · TN TYPE

PROPER INSTALLATION

WRONG INSTALLATION

Note. RST, Classic nomenclature; L1L2L3, current nomenclature

Loading...

Loading...