Chapter 11 Port Explanation

97

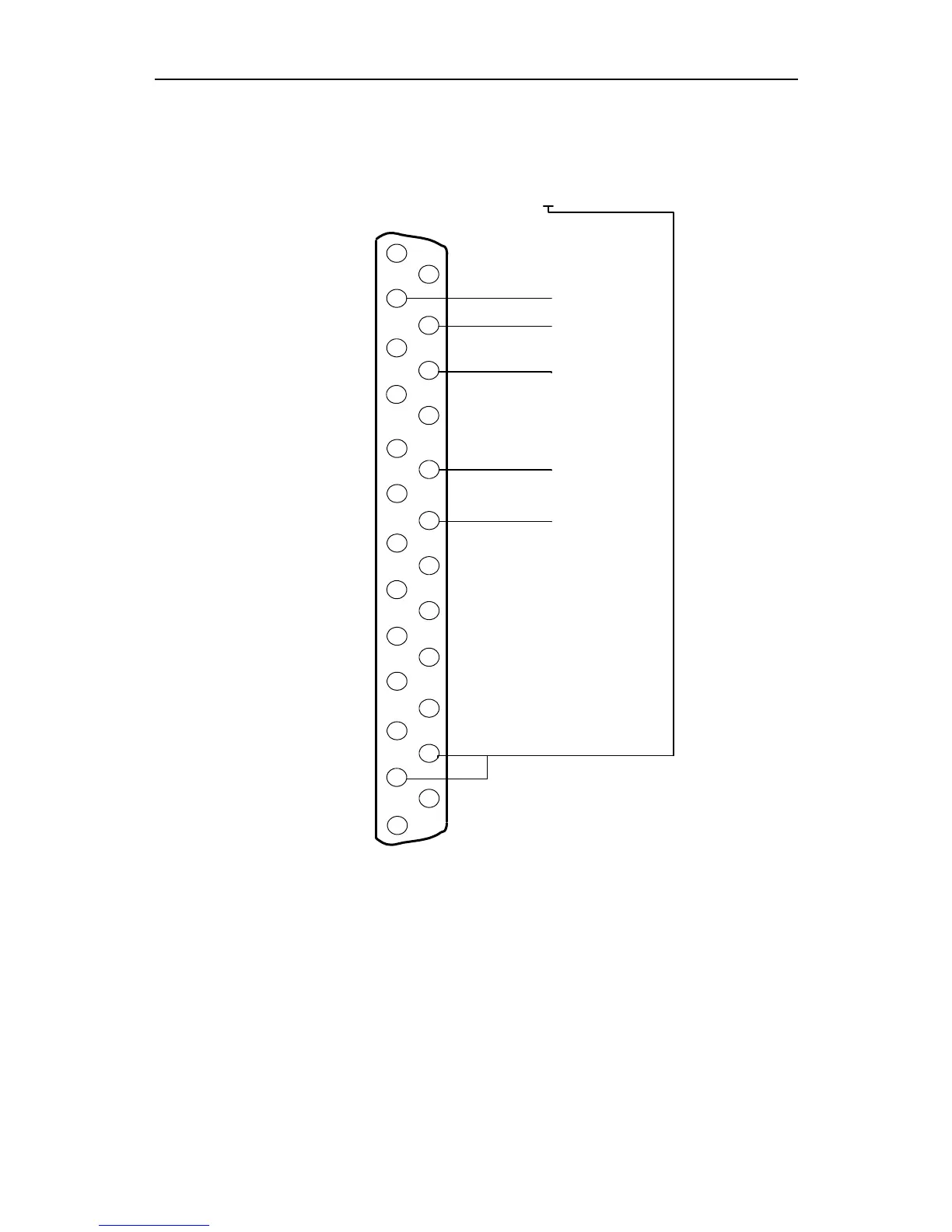

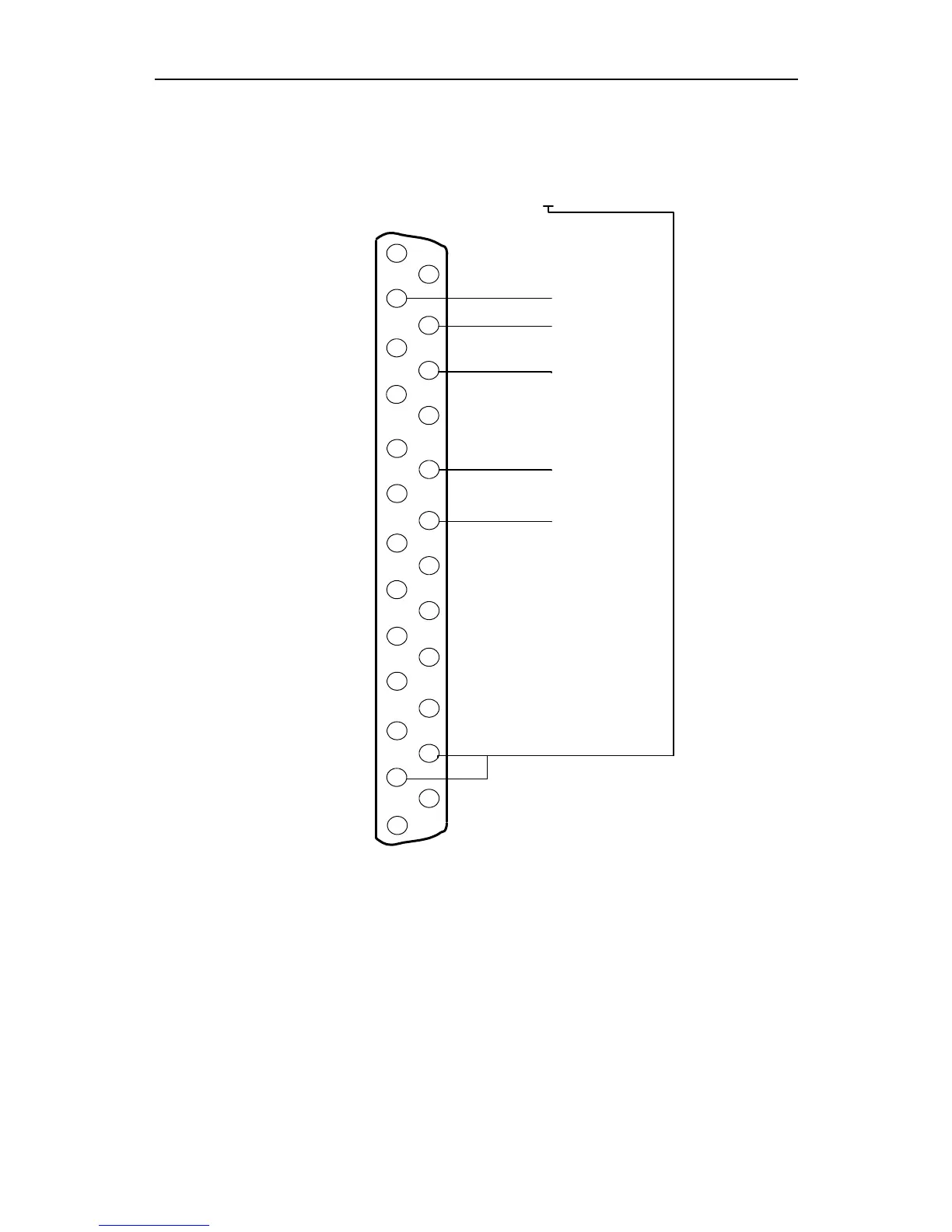

11.2.1.4 Typical Circuit of Using Plasma Cutting

1

Low pressure

preheat

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

High pressure

cutting oxygen

Torch up

Torch down

Ignite

Low pressure

cutting oxygen

Medium

pressure cutting

oxygen

Exhaust

Plasma

High pressure

preheat

Corner low speeed

Plasma locating

Spray dust

Raise dust

Enable high

adjusting box

Dusting preheat

Not used

Not used

Not used

Not used

+24V

+24V

+24V

24VG

24VG

COM

Note:All outputs

are low active or

high active, the

system takes low

active as default.

(Connecting to the system’s

+24V supply,also external

24VSwitch supply +24V port

allowed)

+24V(common)

Torch up control

Torch down control

Connect to high

adjusting device’s

arc starting input or

arc starting delay

Connect to high

adjusting device’s

corner low speed or

automatic / manual

Connect to the locating

input of lifting device

when CNC locating is

needed

(Low active)

(Low active)

(Low active)

(Low active)

(Low active)

Fig 11.7 Typical wiring diagram of the plasma

Instruction:

Height-adjusting device wiring with corner low-speed

When the height-adjusting device takes corner low-speed input control signal, the

system's "corner low speed" output signal is used to control the height-adjusting device's

corner low-speed input. The system takes an open-collector transistor output, with the

default active low signal. Reference section 8.7.3, set the output port type of close THC

(corner signal) “●”. CNC system needs to output low electrical lever signal with this

Loading...

Loading...