Chapter 10 Code Explanation

80

Y

X

Descartes coordinate

system

Fig 10.1 Descartes coordinate system

Of course, the system also can be defined coordinate system by user, referencing

“8.7.4 Coordinate definition”.

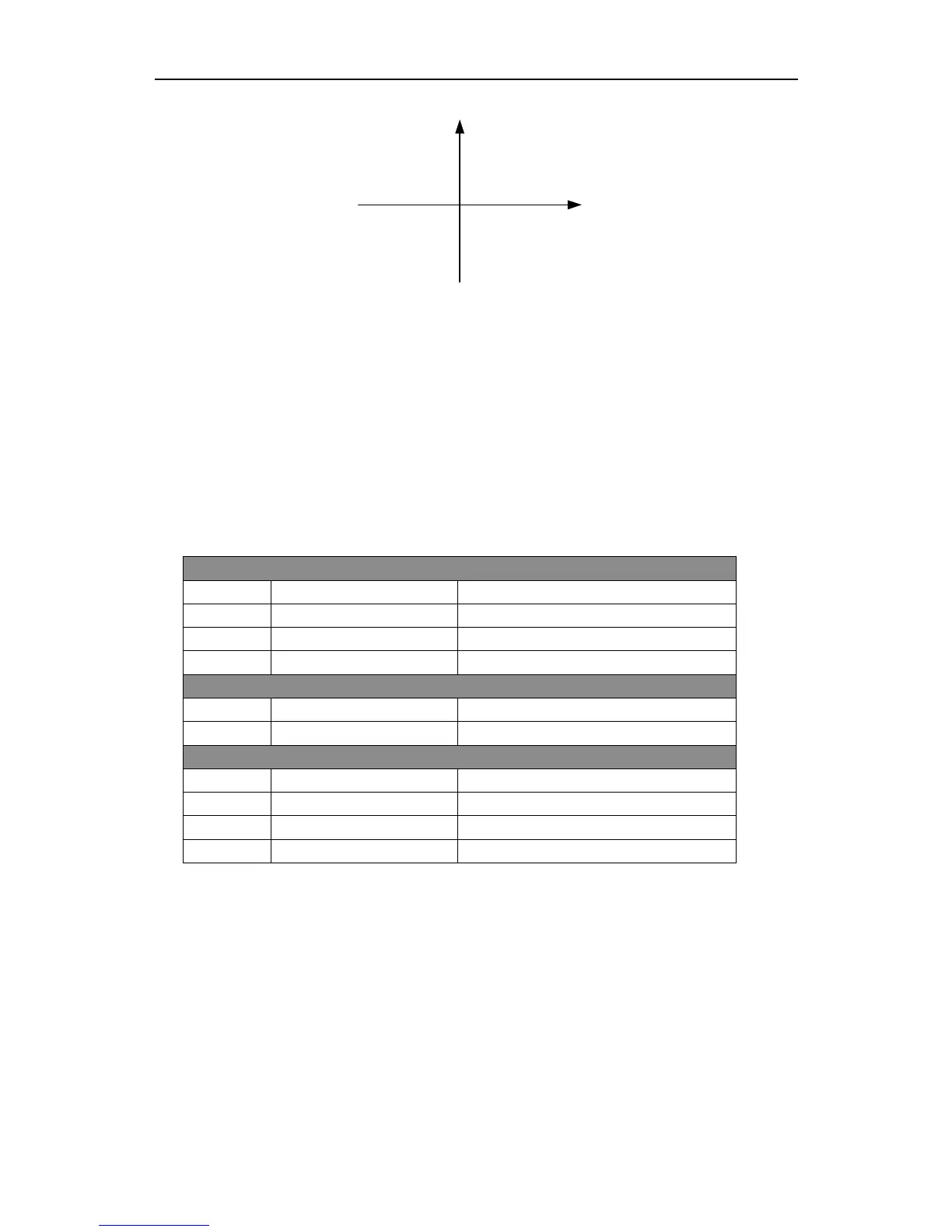

10.3 G Code Explanation

The G code which this system supports for is shown as the table 10.2.

Table 10.2 Common G code table

G99 Parameter: X/U Y/V I J Part option parameter

G92 Parameter: X Y Reference point setting

G91 / G90

No parameter Left/right Kerf compensation

G40 No parameter Cancel Kerf compensation

G00 Parameter: X/U Y/V straight line rapid moving tool

G01 Parameter: X/U Y/V Straight line cutting

G02 Parameter: X/U Y/V I J Clockwise arc cutting

G03 Parameter: X/U Y/V I J Anticlockwise arc cutting

1. G92 Reference point setting

Format:

G92 【Xn】 【Yn】

Parameters meaning:

【Xn】【Yn】 expresses absolute coordinate of reference point to be set and is also

absolute coordinate of which machine tool goes back to. If no parameter after G92, the

default reference point coordinate is (0, 0). Generally, while machine tool is taking (0,0) as

reference point, this code can be ignored.

Note:

Loading...

Loading...