14

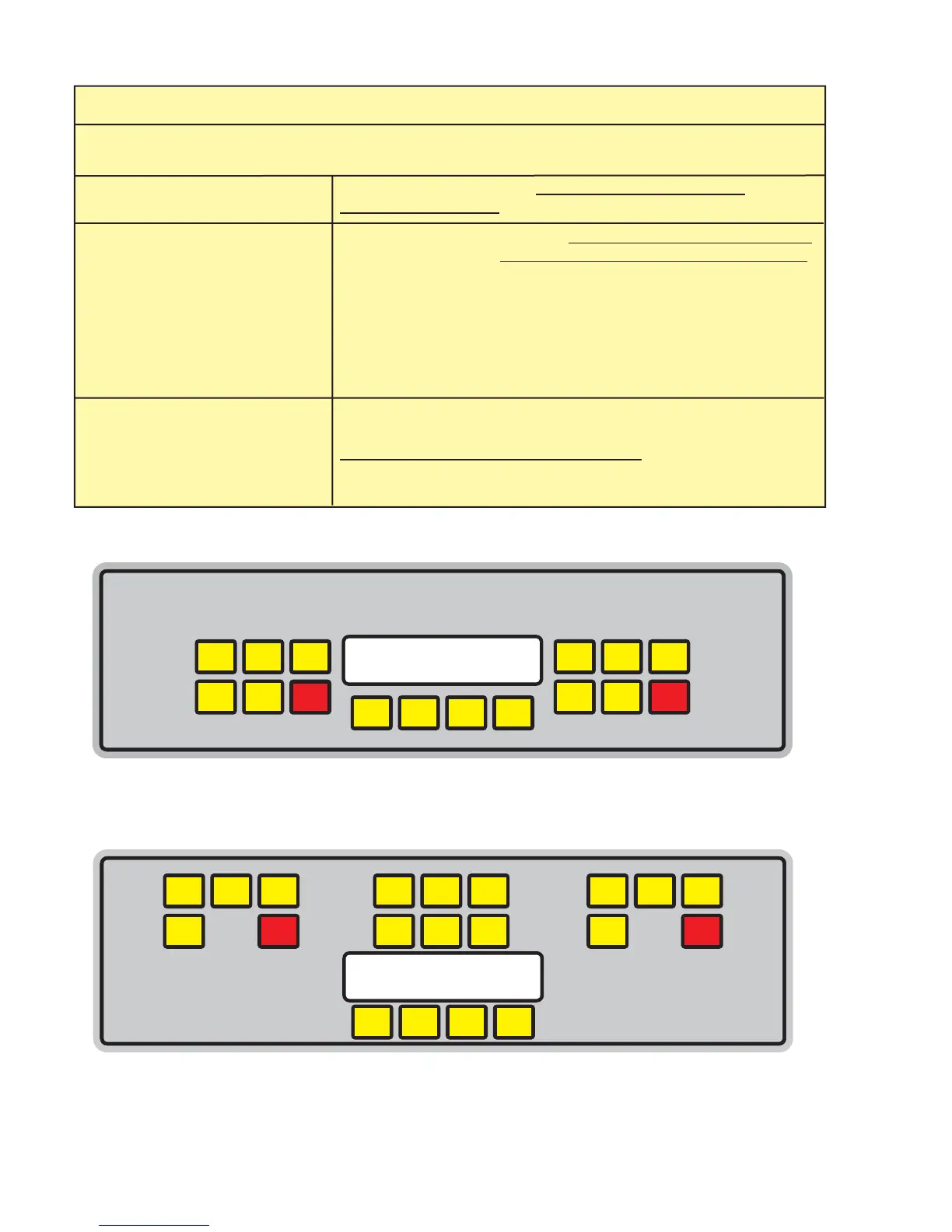

FBD

FWDBACK SELECTCANCEL

OFF

RIGHT SIDE

FILL BEATER

RUN

DEF.

LEFT SIDE

FILL BEATER

RUN

OFFDEF.

CENTER

FILL BEATER

RUN

OFFDEF.

CRITICAL REGULATOR AND FLOW CONTROL SETTINGS

SET ALL PRESSURES USING THE LCD READOUTS ON THE UNIT - NOT BY THE GAUGES ON THE

REGULATORS!

CO

2 PRIMARY REGULATOR The CO2 Primary Regulator MUST BE SET TO 70-72 psig

(482.6 TO 496.4 kPag).

CO2 SECONDARY REGULATOR The CO2 Secondary Regulator SHOULD BE SET AT 28-32 psig

(Secondary Regulator) (193.1 TO 220.6 kPag) STATIC PRESSURE.

For low carbonation applications, see Quick Reference Sheet on

page 4 for settings information. The CO2 Secondary Regulator is

on the header assembly which is behind the access panel. This

regulator is a “non-vent” regulator. This means that if you lower

the regulator setting, you will need to dispense drinks (with “Fill”

activated) until cylinder begins to refill before the new setting will

register on the gauge.

FLOW CONTROLLERS WATER FLOW MUST BE SET TO PROVIDE A FLOW OF

15 OUNCES IN 10 SECONDS BEFORE ADJUSTING THE BRIX.

BRIX MUST BE SET BETWEEN 13.5 - 15. Flow controllers are on

the header assembly. A sample may be taken by fully opening the

sample valve, by turning it clockwise until it stops.

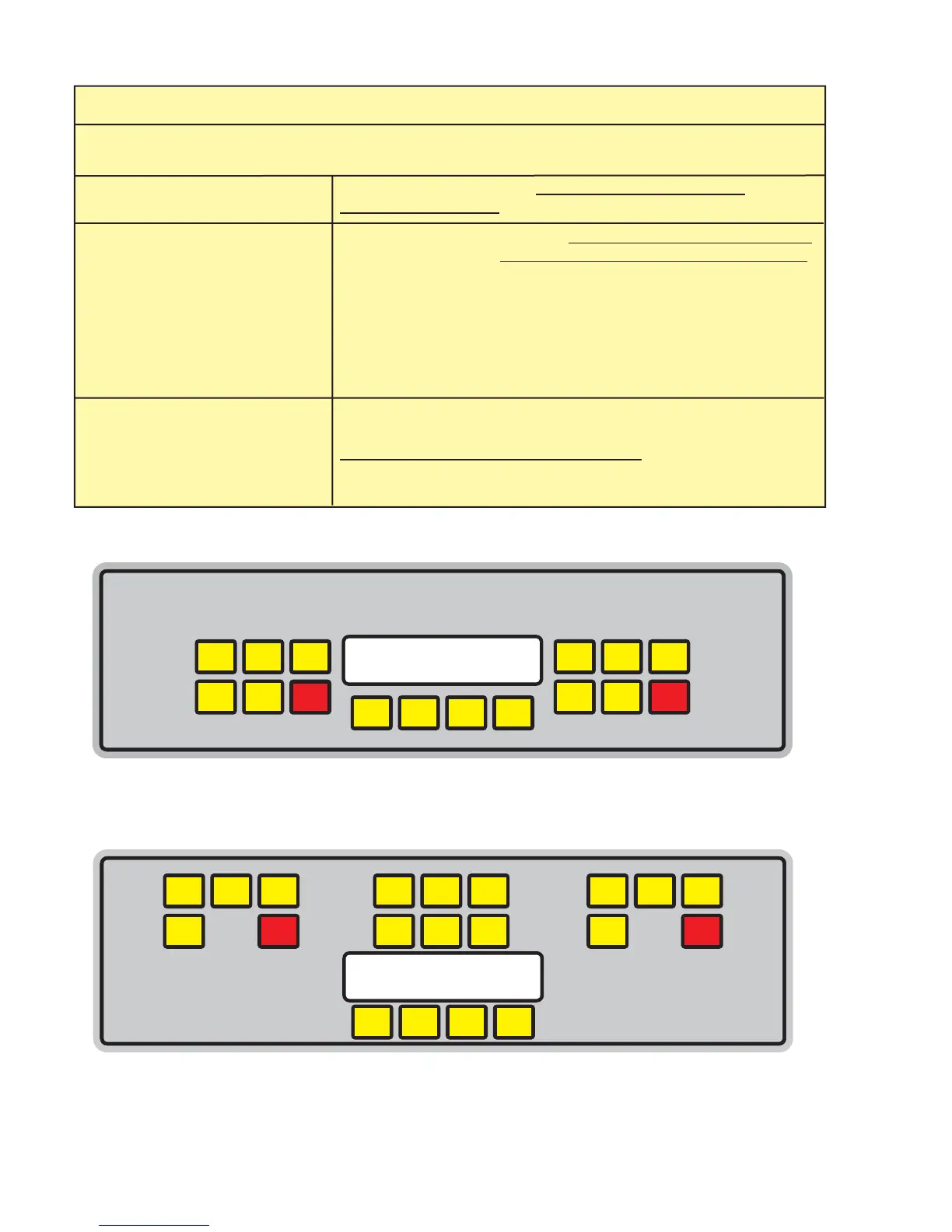

FBD563 Contols

Figure 7.1b

FBD

FWDBACK SELECTCANCEL

OFF

RIGHT SIDE

FILL BEATER

RUN

DEF.

LEFT SIDE

FILL BEATER

RUN

OFFDEF.

FBD562 Contols

Figure 7.1a

Loading...

Loading...