NOTE:

H2O readout will be 15-20

psi higher on the readouts.

Keep regulated pressure at

70-72 psig.

28

2. Install booster pumps in the supply lines. Use a vacuum regulating valve with syrup booster

pumps.

3. Increase primary CO

2 regulator pressure from bulk or tank CO2 to 105 - 120 psig (723.9 to 827.4

kPag). A secondary regulator will be necessary for pumps (syrup, water) to avoid exceeding

manufacturer’s recommended operating pressures.

13. TROUBLESHOOTING GUIDE

The following information is a listing of the most common problems that could keep the FBD56X Series

Dispenser from operating properly. Contact the factory for details, when necessary.

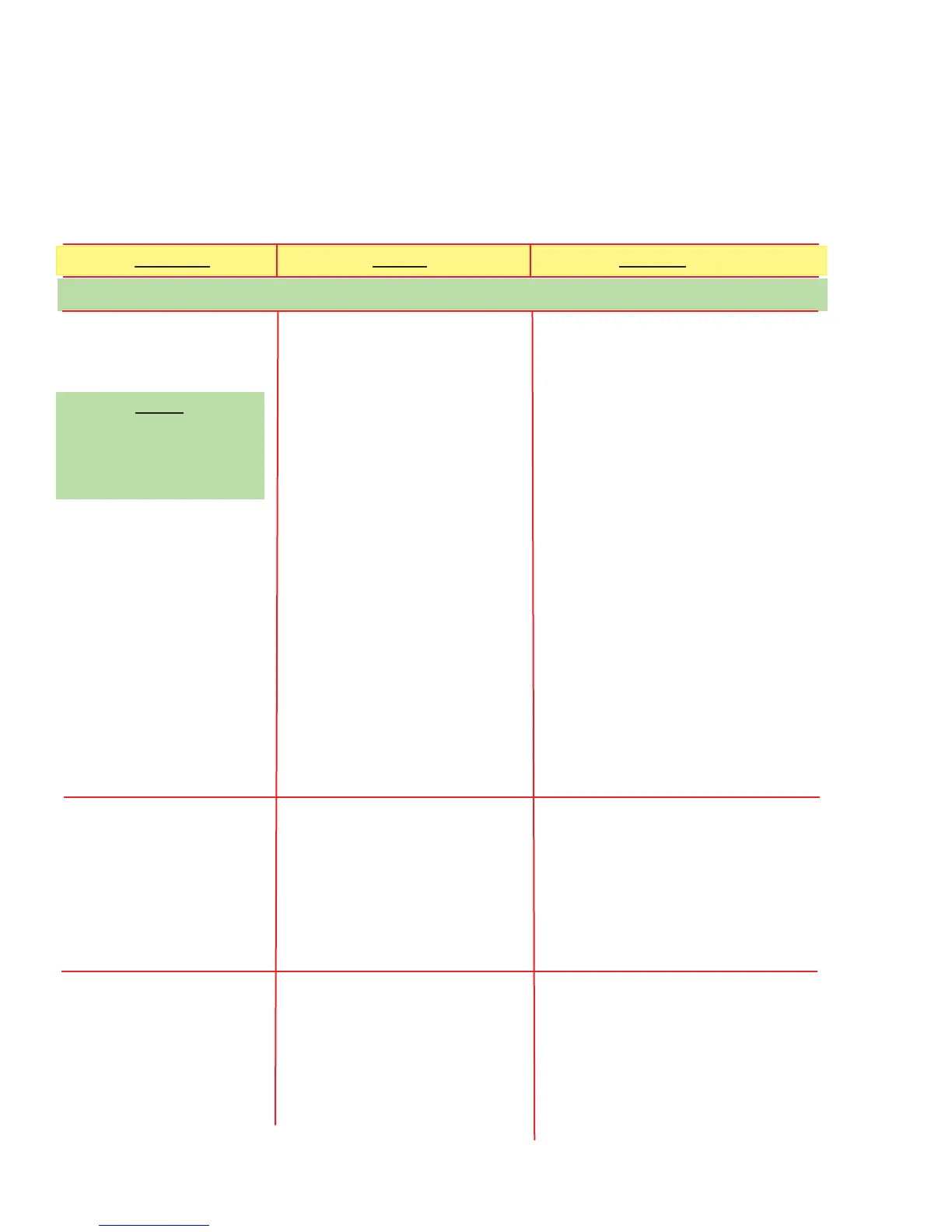

TROUBLE CAUSE REMEDY

MECHANICAL

13.1 Chamber will not fill. A. “Fill“ off. A. Press “Fill” button. “Filling” or

“Fill Hold” will appear on LCD

display.

B. Pressure in chamber above B. Gently pull faceplate relief valve

“RFill” (refill) point. ring to relieve pressure in chamber.

C. “Defrosting” or “Sleeping”. C. Press “Def,” then “Run.” Wait for

unit to freeze and red light to go

out.

D. Out of CO2, Syrup or Water. D. Check LCD messages for

“Out of …….” condition.

E. Tank Pressure readout not E. Observe “Tank Transducer” in

moving between 18 and “Readouts”. Check transducer and

40 psig or doesn’t lower when replace if necessary.

chamber pressure is reduced.

F. Solution or CO2 solenoid F. In “Manual On/Off, energize

valve won’t open. solenoid and check for 24VAC at

coil. Clean or replace solenoid if

necessary

G. Relay board not sending G. Test solenoid relay on relay board

power to solenoid coils. for 24VAC output and 5VDC input.

Replace Relay Board, if necessary.

H. Lower Board problem. H. Check Lower Power Board for +5,

+15, and –15 indicator lights. If

green lights are not energized,

replace board, if necessary.

I. 192 VA Transformer problem. I. Test transformer for 220VAC input.

Also check for 24VAC and 12VAC

output (see Figures 14.7-14.13).

Replace transformer if necessary.

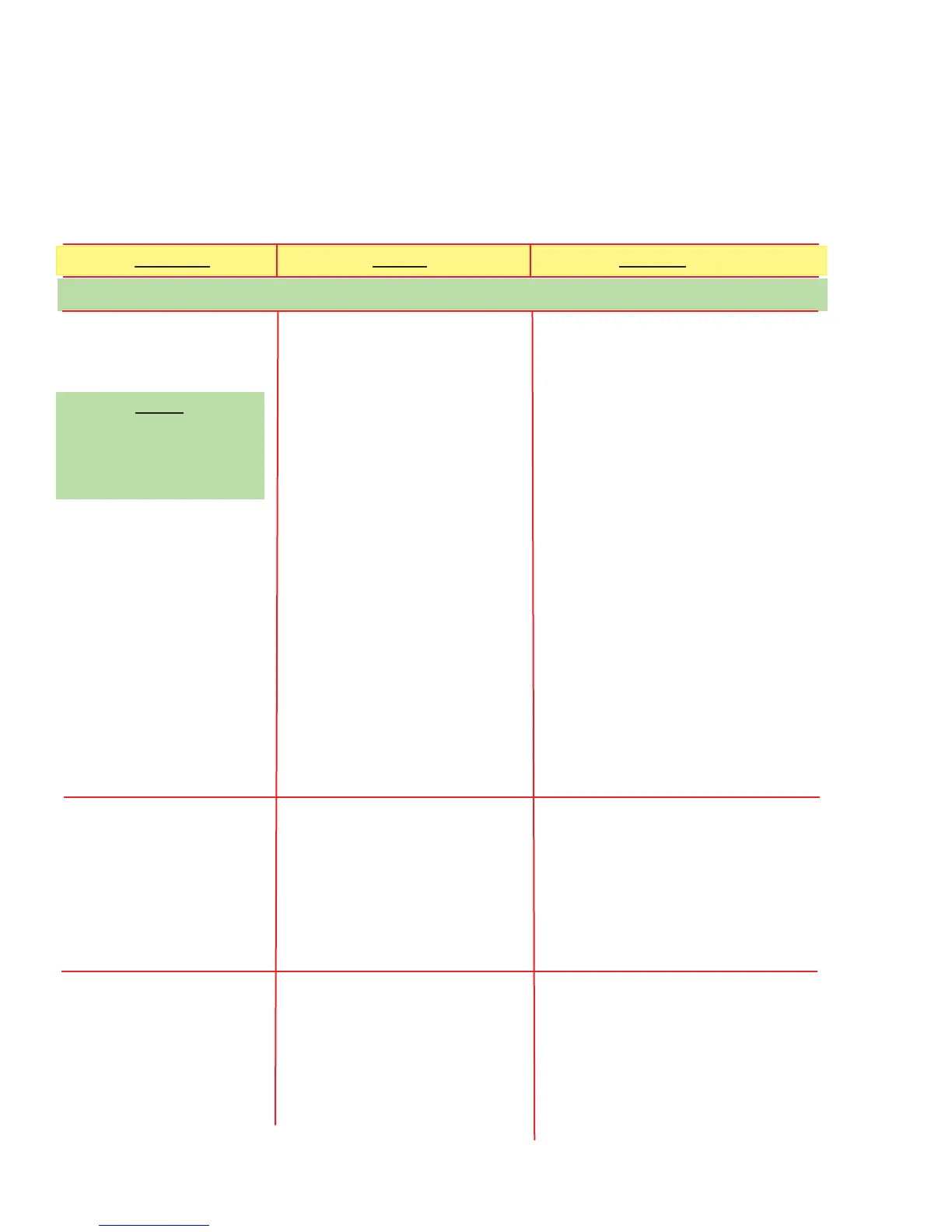

13.2 Chamber fills even A. Solution solenoid plunger A. In “Manual On/Off”, energize

when turned off sticking. solenoid and check for 24VAC at

coil. Clean or replace solenoid, if

necessary.

B. Solution solenoid energized. B. Test solenoid relay on relay board

for 24VAC output and 5VDC relay

coil input. Replace Relay Board, if

necessary.

C. Solution solenoid left “ON” C. In “Manual On/Off”, turn solenoid

in “Manual”. off.

13.3 Out of Product A. Unit receiving no water, syrup A. Assure water is on and CO2 supply

displayed (Out of and/or CO2. is not empty or turned off. Also

Water, Syrup or CO2). check to see that syrup container

is not empty and is hooked up.

B. Restriction in lines. B. Assure all lines are free of crimps

or restrictions.

C. Regulator pressures (unit C. Check pressure readouts (H2O,

and syrup pumps) too low. CO2 and Syrups) for 70-72 psig.

Adjust regulators, if necessary.

(Item 13.3 continued on next page.)

Loading...

Loading...