29

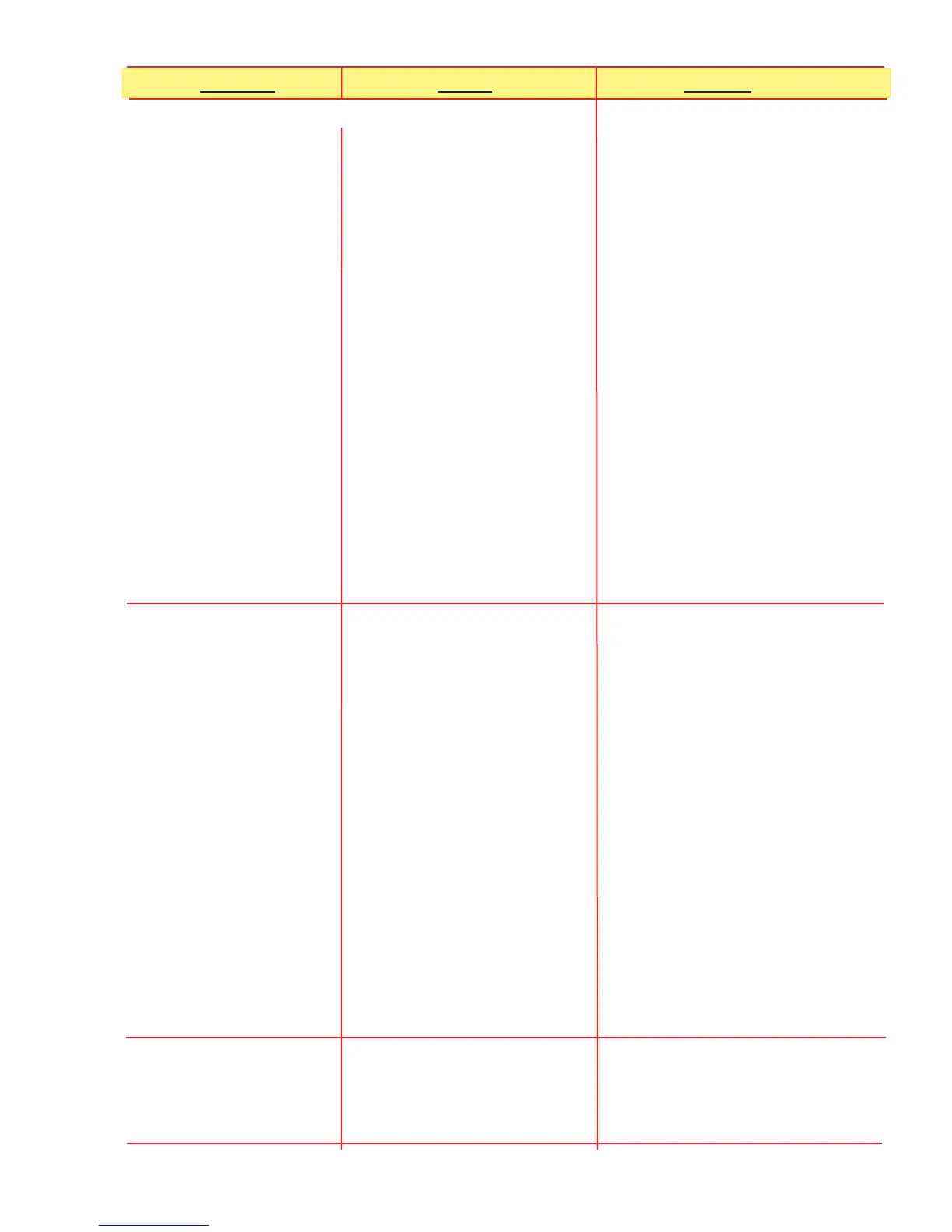

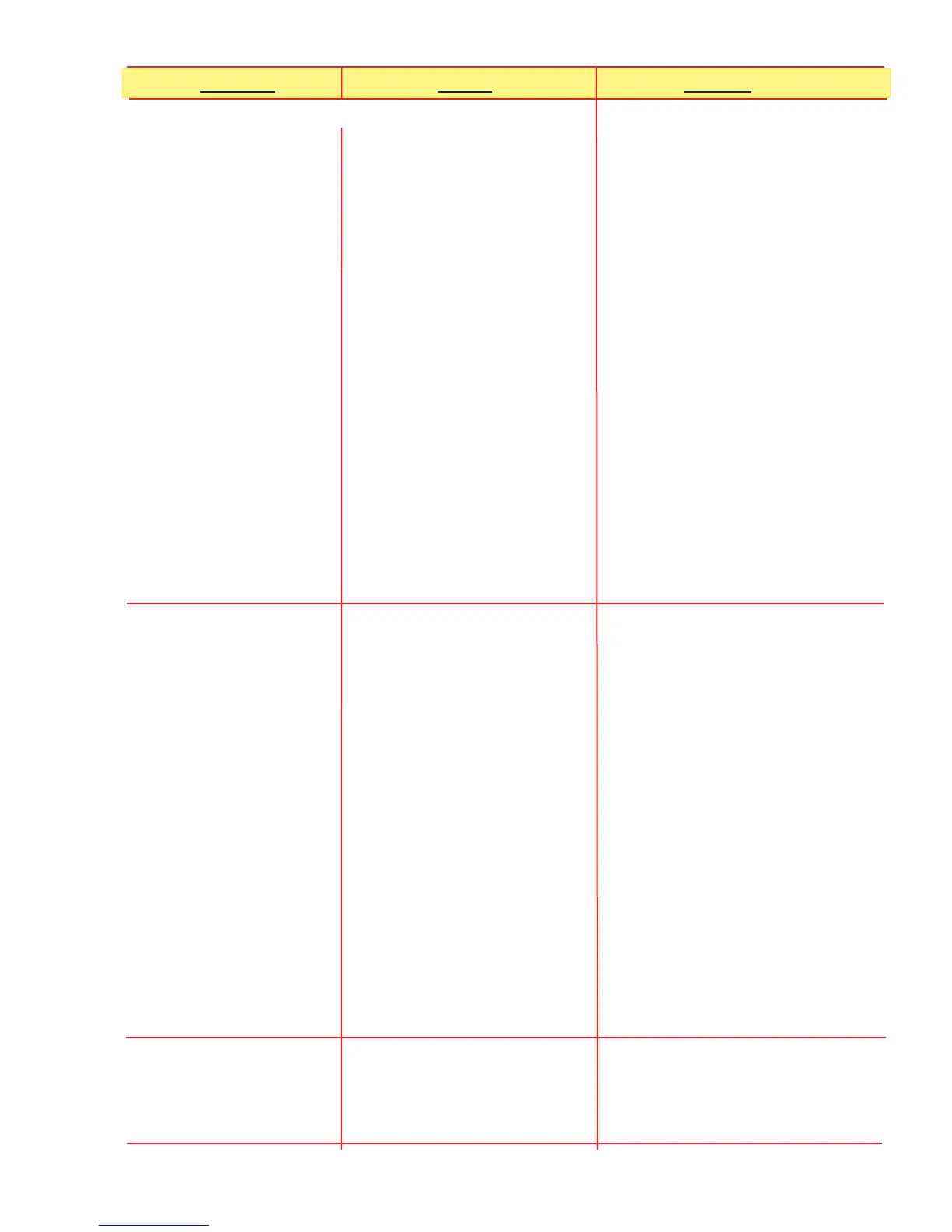

(Item 13.3 continued from previous page.)

D. Syrup or Water Pump failure. D. Check all pumps and replace, if

necessary.

E. CO

2 or water can’t keep up E. Reroute water or CO2 lines to

with unit demand. maximize supply pressure. Install

Water Booster if necessary.

F. Excessive pressure drops F. Observe “Syrup Press” readouts

in syrup lines. as chamber fills to verify. Increase

line diameter or relocate syrup

source closer to unit. Syrup

pressures may only be raised (by

increasing pump CO2 pressure)

if separate regulators are installed

for unit and syrup pumps. Never

exceed pump manufacturer’s

recommended maximum CO2 inlet

pressure (see Section 12.4).

G. Transducer problem (H2O, G. Check pressure readouts (H2O,

CO2 or Syrup). CO2 and Syrup) for 70-72 psig. If

not within 2 psi, adjust regulator

and/or check transducer. Replace

transducer, if necessary.

H. Lower Board problem H. Check Lower Power Board for +5,

+15, and –15 indicator lights. If

green lights are not energized,

replace board, if necessary.

I. Upper Board Problem I. Circuits within Main Control (Upper)

Board electronics read transducer

pressures. Replace Main Control

(Upper) Board, if necessary

13.4 Product does not flow A. Faulty CO2 check valve. A. Inspect CO2 check valve. Clean or

freely or does not flow replace.

at all from dispensing B. CO2 solenoid valve won’t B. In “Manual On/Off, energize

valve. open. solenoid and check for 24VAC at

coil. Clean or replace solenoid, if

necessary.

C. Solution solenoid valve C. In “Manual On/Off”, energize

won’t open. solenoid and check for 24VAC at

coil. Clean or replace solenoid, if

necessary.

D. Ice particles in dispensing D. Run defrost cycle. If necessary,

valve. open and close dispensing valve

several times or run warm water

over valve.

E. Product in cylinder is frozen E. 1. Check water/syrup flow

too hard or solid. rates and brix. Adjust, if

necessary (see Section 6.2).

2. Check Level Control setting.

Adjust if necessary (see

Section 10).

3. Check Thaw/Freeze settings.

Adjust if necessary (see

Section 11).

4. Defrost chamber. Assure

chamber is filled to 90%, then

press “Run”.

13.5 Product leaking from A. Beater drive seal is worn or A. Replace with new seal.

rear of cold pack. damaged.

B. Beater drive coupling is worn. B. Replace coupling.

C. Seal is not positioned C. From inside chamber, reseat seal,

correctly. making sure it is flush with back of

chamber.

TROUBLE CAUSE REMEDY

Loading...

Loading...