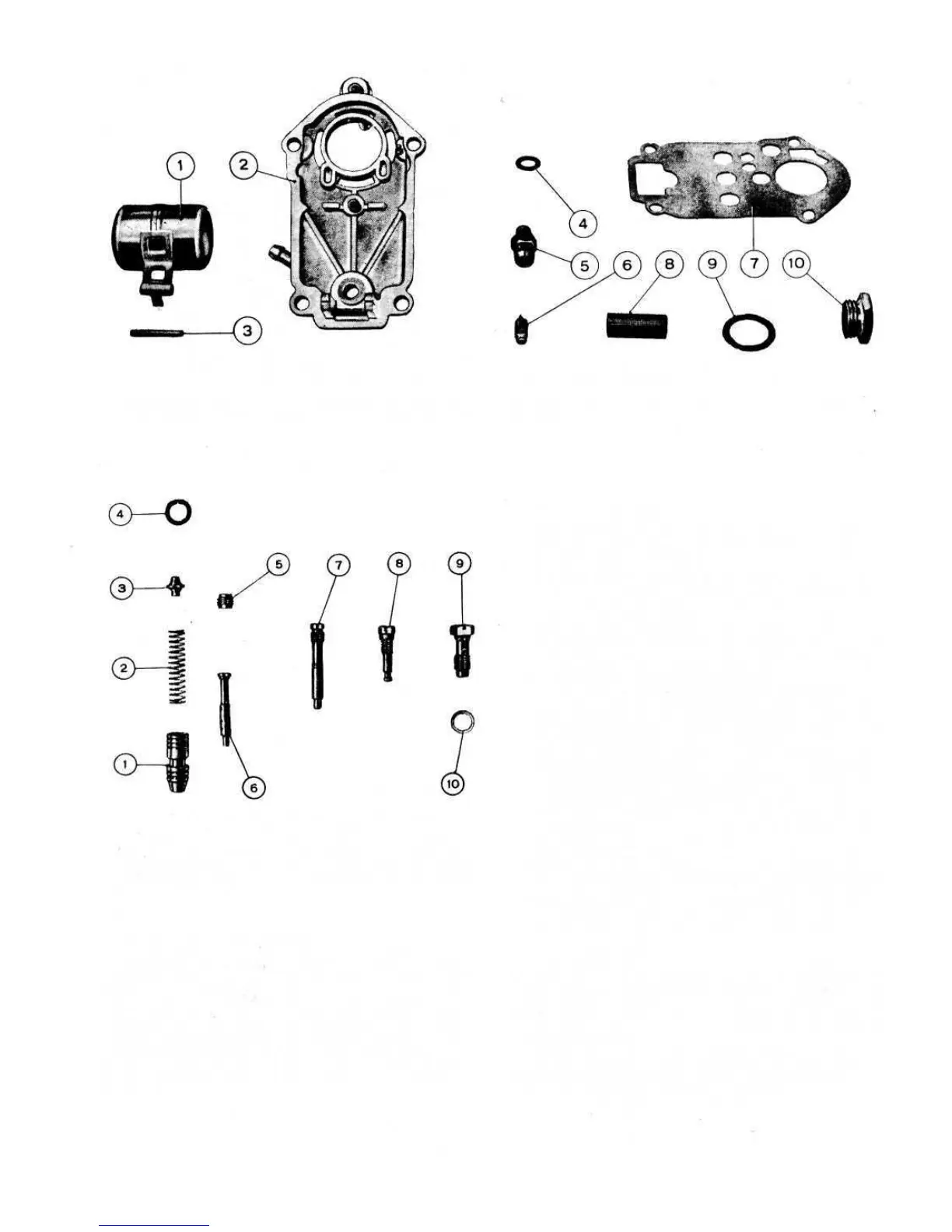

FIG 2:9 Weber 26.IMB carburetter cover components

Key toFig 2:9 1 Float 2 Carburetter cover 3 Float pivot 4 Needle valve gasket 5,6 Needle valve seat and needle valve

7 Cover gasket 8 Filter strainer 9 Gasket 10 Filter inspection plug

Carburetter cleaning:

To thoroughly clean the carburetter proceed as follows:

1 Passages. All fuel passages have a diameter that is

specially calibrated to ensure best operating conditions.

It is therefore essential that any dirt or scale that has

been deposited by petrol must be removed. Thoroughly

clean with petrol and blow dry using a compressed air

jet directed through all the passages in the castings. It is

essential that no drills or other metal objects be passed

through the jets or the passages otherwise these could

alter the finely calibrated diameters.

2 Calibrated parts. Idling and main jet holders, and the

relevant bayonet coupled jets are easily removed by

using a suitably sized wrench or screwdriver. To clean

the different calibrated parts, thoroughly wash in petrol

and blow dry using a compressed air jet. Do not use any

fine drills or metallic points as these may alter the fine

calibration of the orifices. Should it be necessary to dis-

mantle the carburetter adjustment components for

inspection always ensure that after reassembly of the

parts that they are seated correctly to avoid possible

operating troubles in the future.

3 Filter. To clean the filter unscrew and remove its plug

10 (see FIG 2 :9) located on the top of the carburetter

cover and then gently ease out the filter. Wash the filter

carefully in petrol, also ensure that the filter seat is clean

and then blow dry using a compressed air jet.

2:7 Modifications

The Weber 26.IM B carburetter has undergone a number

of minor changes during the development of the Fiat 500

models, but no changes in servicing procedure are made

necessary. Jet sizes and other calibrations are detailed

in Technical Data.

From 1970, the mounting flange of the carburetter is

slightly modified to incorporate a different mixture

adjustment screw, as shown in FIG 2:11.

40

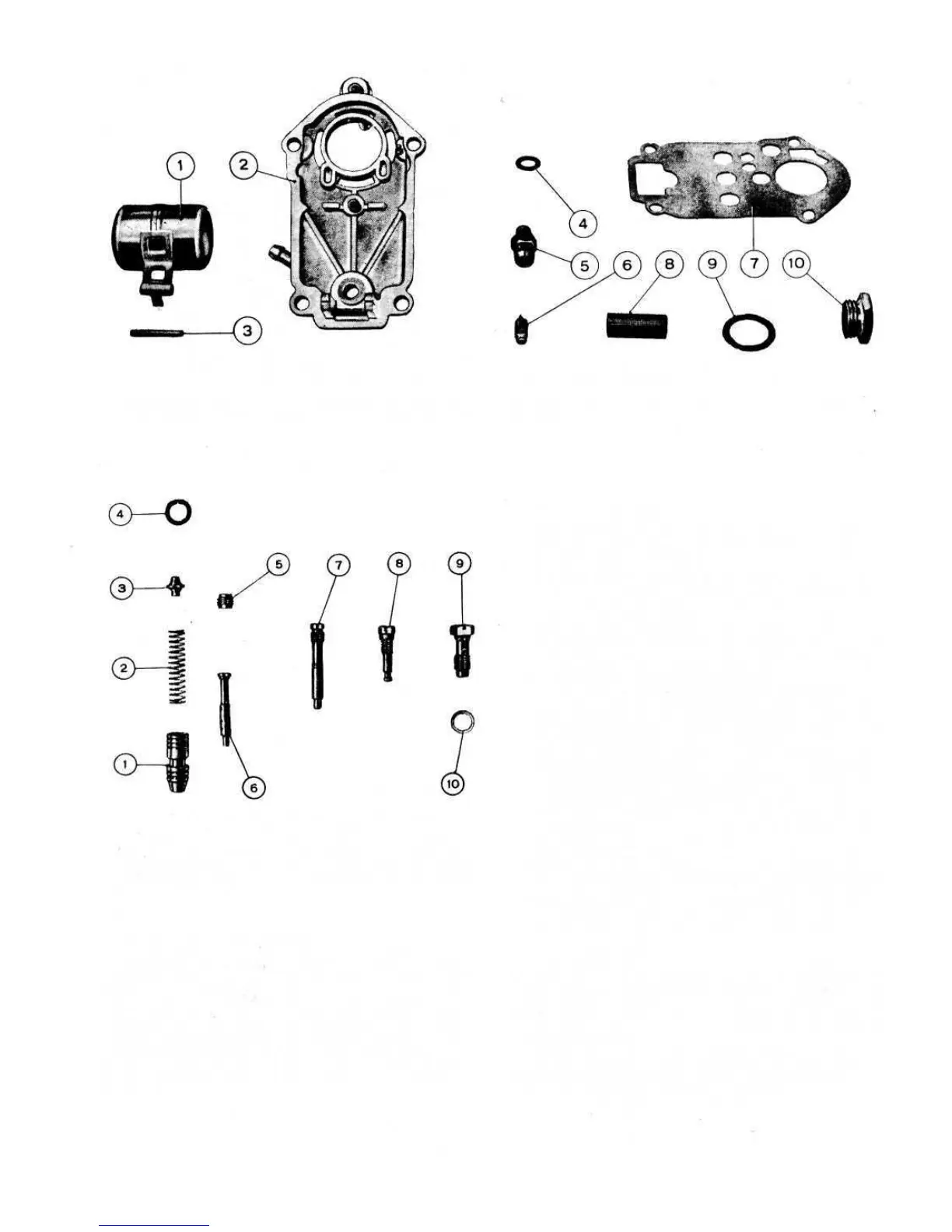

Throttle valve components:

The throttle valve shaft should rotate freely in its guides

and this should be checked when the engine is at its

normal operating temperature. Any excessive clearance

caused by wear or the throttle valve butterfly distorted are

liable to cause irregular engine operation which will be

more pronounced at idling speed. Should the above con-

ditions be evident then the throttle valve butterfly and the

shaft assembly together with its sealing rings must be

renewed.

FIG 2:10 Jets, jet holders and choke valve

Key to Fig 2:10 1 Choke valve 2 Spring

3 Spring retainer and guide 4 Lock ring 5 Air bleed jet

6 Emulsion well 7 Choke jet 8 Idling jet holder and jet

9 Main jet holder and jet 10 Main jet holder gasket

Loading...

Loading...