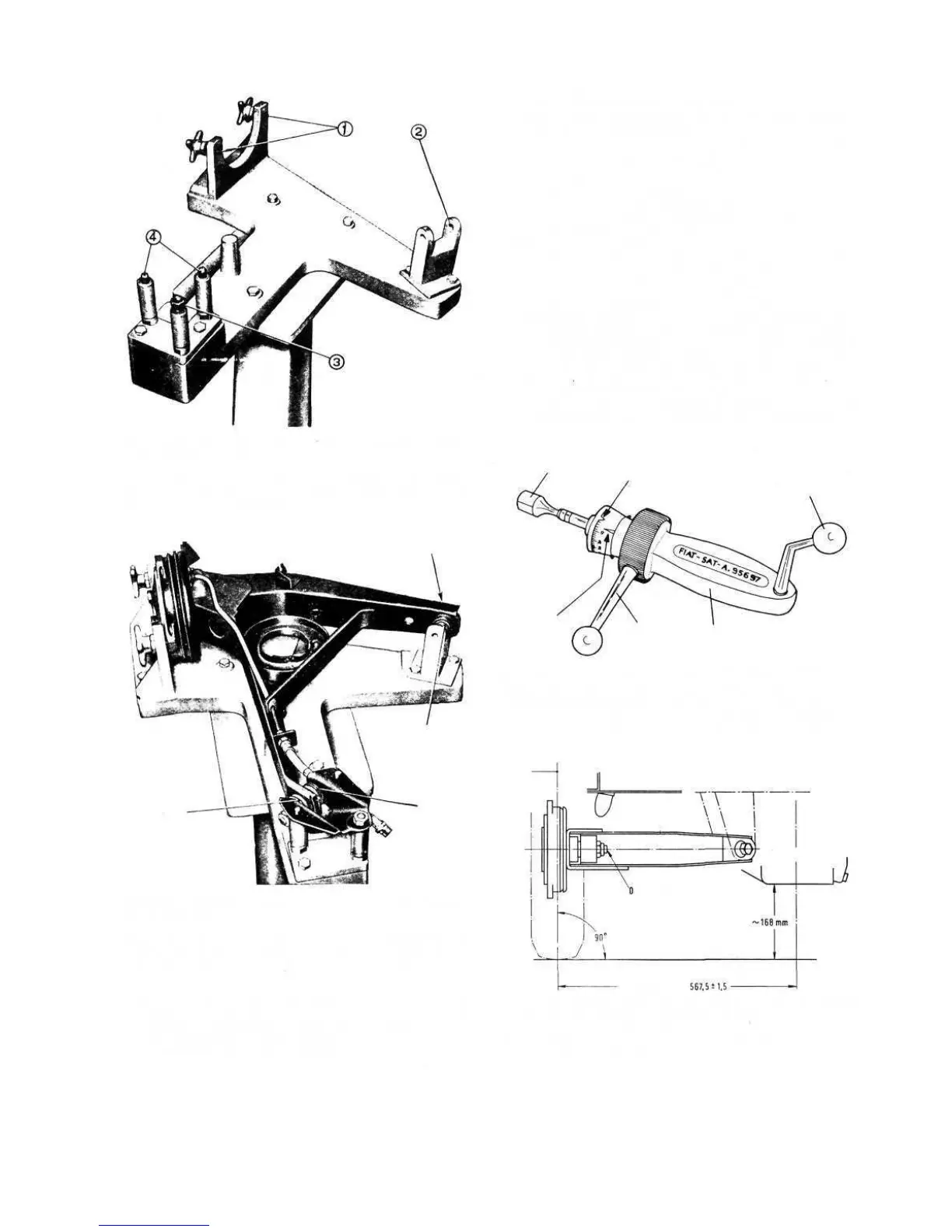

FIG 7:3 Fixture A.66064, for swinging arm inspection

and adjustment

Key to Fig 7:3 1 Clamp screws, securing wheel shaft on

fixture 2 Alignment bracket, swinging arm member check-up

3 Nut, to secure swinging arm external support on fixture stud

4 Swinging arm external support centring pins

A

B

C

D

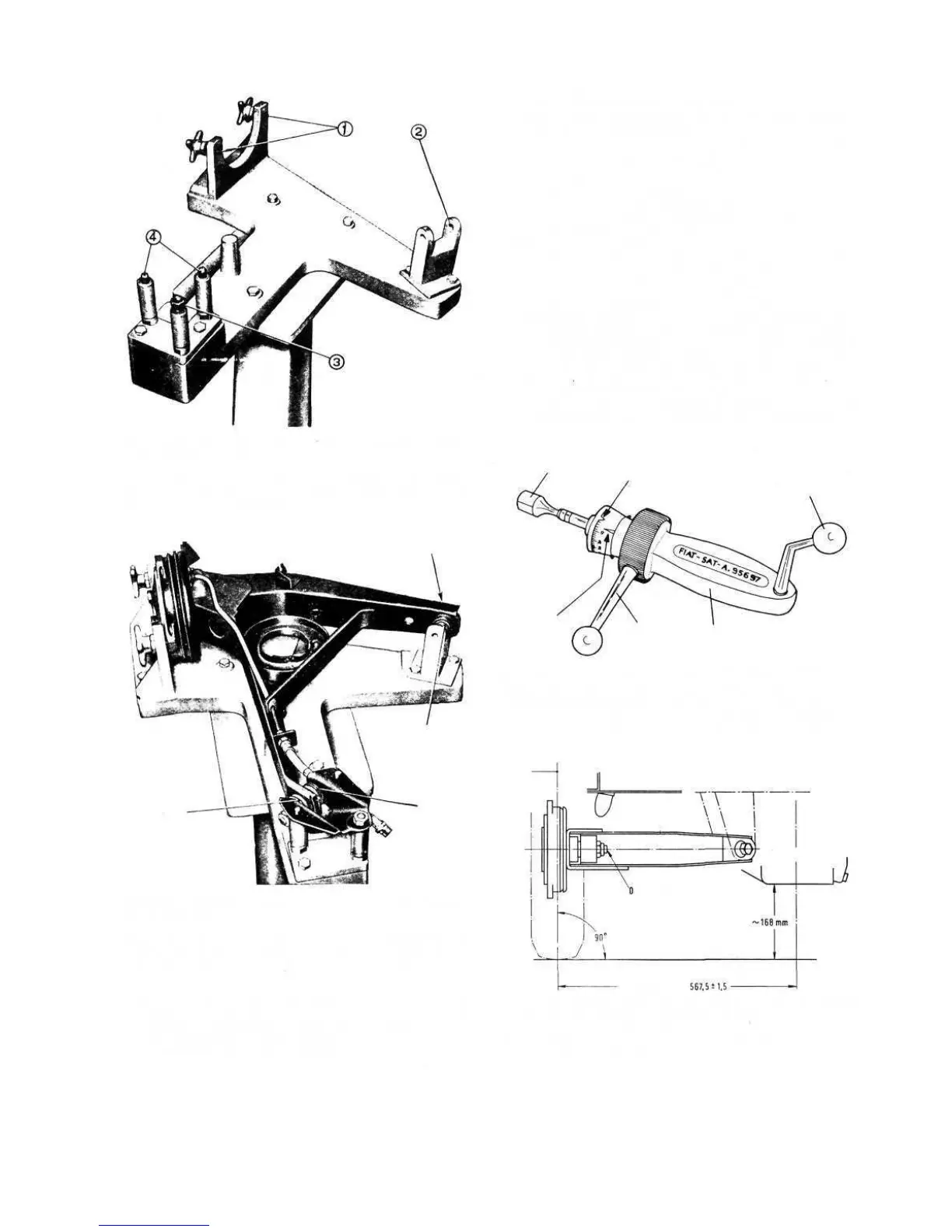

FIG 7:4 Adjusting right rear suspension swinging arm

on fixture A.66064

Key to Fig 7:4 A and B Swinging arm external support

adjustment shims C and D Swinging arm internal support

adjustment shims

torque wrench setting of 43.4 Ib/ft.

3 During assembly the bearings must be packed with

Fiat MR grease, taking care not to overpack as this

can result in early bearing failure.

82

4 If the axle shaft to flexible joint tie sleeve has been

removed, the mating splines must be coated with Fiat

B2G grease on re-installation.

5 Preload the wheel bearings and adjust the swinging

arm as described later on in this section.

Wheel bearing adjustment:

To ensure a long bearing life due to correct initial

adjustment the ballbearings should be preloaded and to

do this proceed as follows:

1 Tighten the wheel shaft nut gradually so that the

rotation torque does not exceed .36 Ib/ft.

2 To check the rotation torque install Fiat tool A.95697/2

on the wheel drum and insert the shank 2 (see FIG

7:5) of dynomometer A.95697 in the support and

securely hold the lever 3. Move the needle 5 to register

.36 Ib/ft on the dynomometer scale as shown in FIG

7:5 and using the operating lever 6 rotate the dyno-

mometer and the wheel shaft some turns in a clockwise

direction. During rotation check that the needle 5 does

not exceed the setting index 4. Should the rotation

torque prove to exceed .36 Ib/ft, this will indicate a

4

3

1

6

5

2

FIG 7:5 Bearing rotation torque dynamometer

KeytoFig7:5 1 Dynamometer A.95697 2 Dynamometer

shank to insert in item A.95697/2, fitted to wheel drum

3 Dynamometer grip lever 4 Rotation torque setting index

5 Adjustable needle 6 Dynamometer operating lever

Oil Sump

Wheel Plane

HALF TRACK

FIG 7:6 Position of rear suspension and of vehicle for

rear wheel toe-in inspection and adjustment

Key to Fig 7:6 ~ 168 mm = 6.61 inch

567,5 ± 1,5= 22.342 inch ± .059 inch

Loading...

Loading...