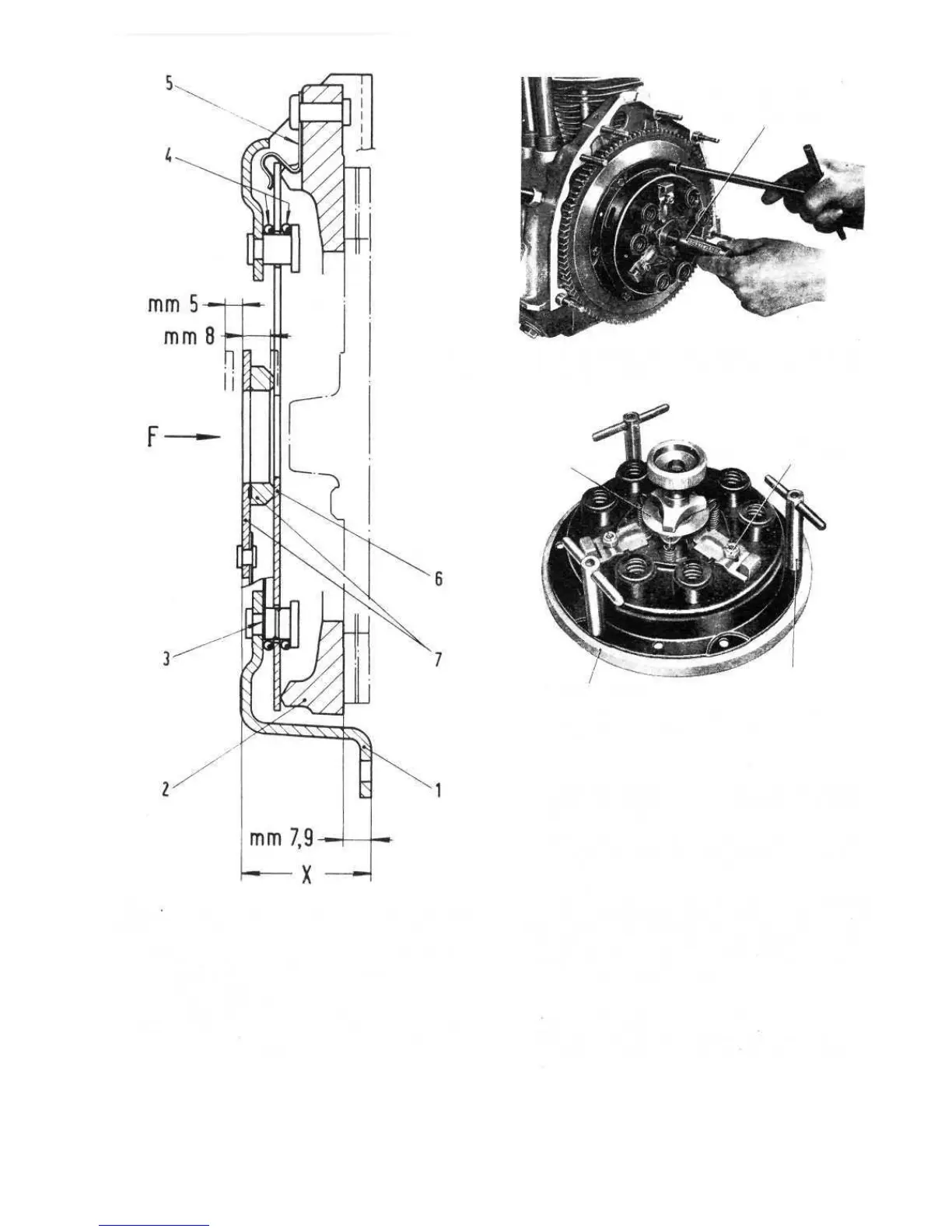

FIG 5.4 Clutch cover assembly inspection diagram

500F, L and later Station wagon

KeytoFig5:4 1 Clutch cover 2 Pressure plate

3 Clutch release flange plate 4 Diaphragm spring rings

5 Diaphragm spring retainer plate 6 Diaphragm spring

7 Clutch release flange

X =1.463 ± .043 inches

F = direction of clutch release flange movement

8 mm = .31 5 inch = release travel

5 mm = .197 inch = maximum allowance for driven plate lining

wear

7.9 mm = .311 inch

62

5:5 Installation of clutch on flywheel

Before assembling the clutch cover assembly and

driven plate the following parts of the unit should be

assembly proceed as follows:

1 Position the clutch cover assembly on Fiat fixture

A.62038 with a spacer .311 inch thick between the

cover and the plate.

2 Operate the clutch mechanism for four complete

throw-out strokes by applying a load of at least 181 Ib

on the release flange as shown by the arrow 'F' in

FIG 5:4.

3 Check that with a withdrawal travel of .315 inch the

pressure plate is displaced .071 inch. Also check that

the distance'X' (see FIG 5 :4) is 1.463 inch ± .043 inch.

Should the results obtained not compare with the

manufacturers recommended figures, then the clutch

cover assembly should be renewed.

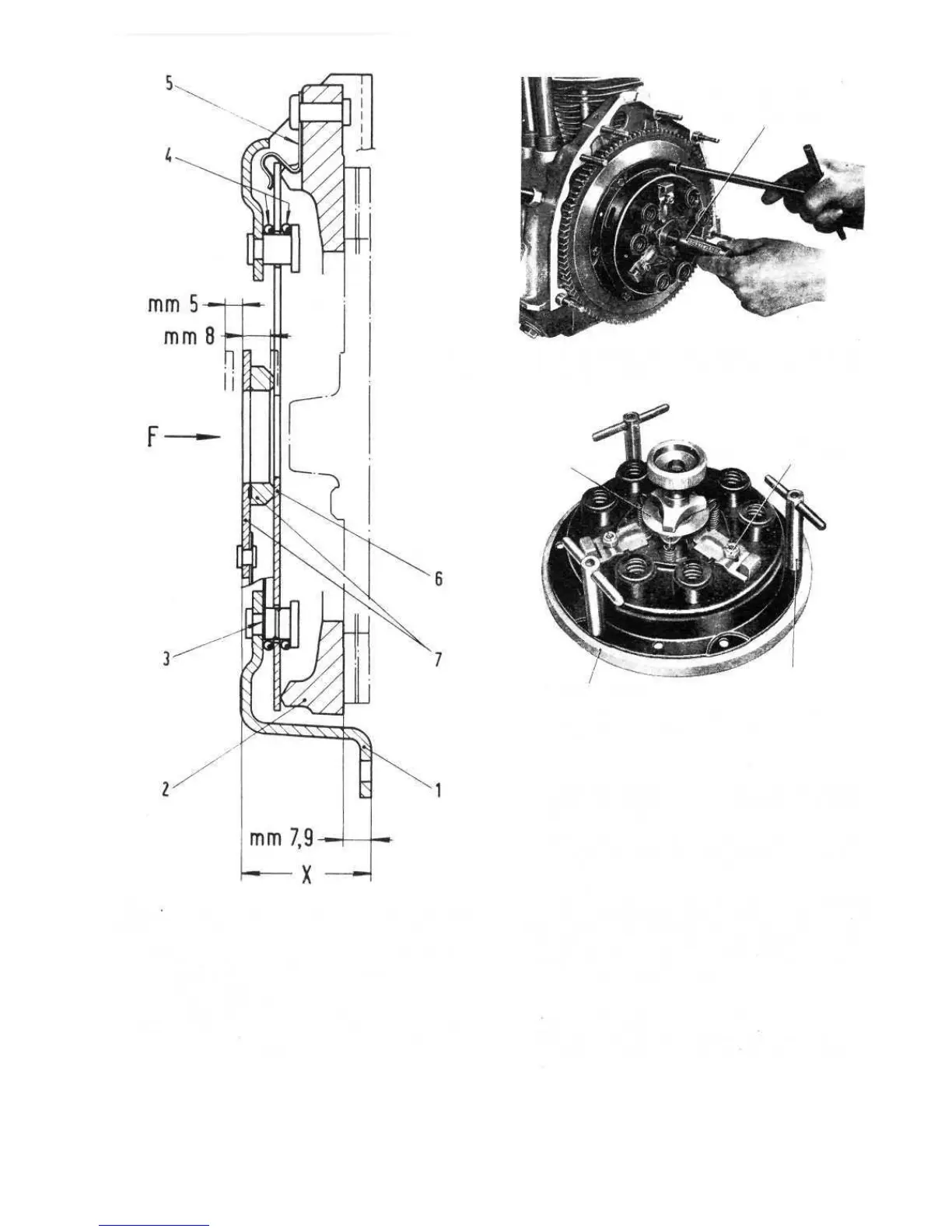

FIG 5:6 Fixture A.62038 for clutch disassembly, re-

assembly and adjustment (new 500, 500D sedan and early

station wagon)

FIXTURE A. 62038

T-HANDLES

CARRIER RING

LEVER

BOLT NUTS

(LEVER ADJUSTMENT)

FIG 5:5 Installing the clutch on flywheel using pilot

A.62023 (new 500, 500D sedan and early station wagon) to

centre the driven plate

PILOT A. 62023 FOR

DRIVEN

PLATE CENTERING

Loading...

Loading...