2322

Fusion

Splicing Process

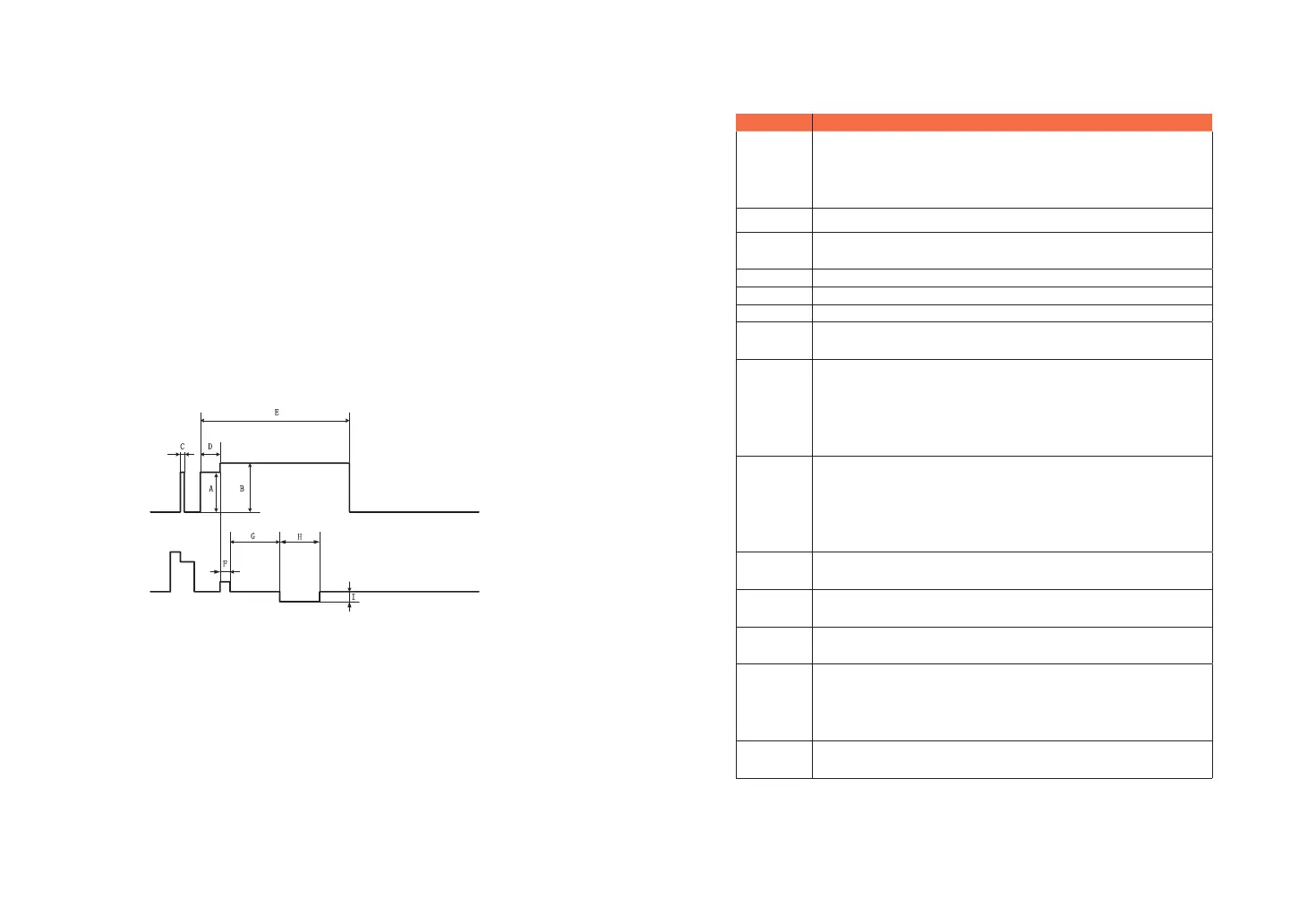

During fusion, the bers are joined together and subjected to ve dierent currents

as illustrated below. An important parameter, which changes during splicing, is

the distance between the bers. During Pre-fusion, the bers are apart. With the

current phase changing, bers are spliced gradually.

The most important splicing parameters are the time and current, each current

phase is shown below, that the name and function and other parameters are

important to the splice process are described under “Parameters for Normal

Splicing Process” on the next page.

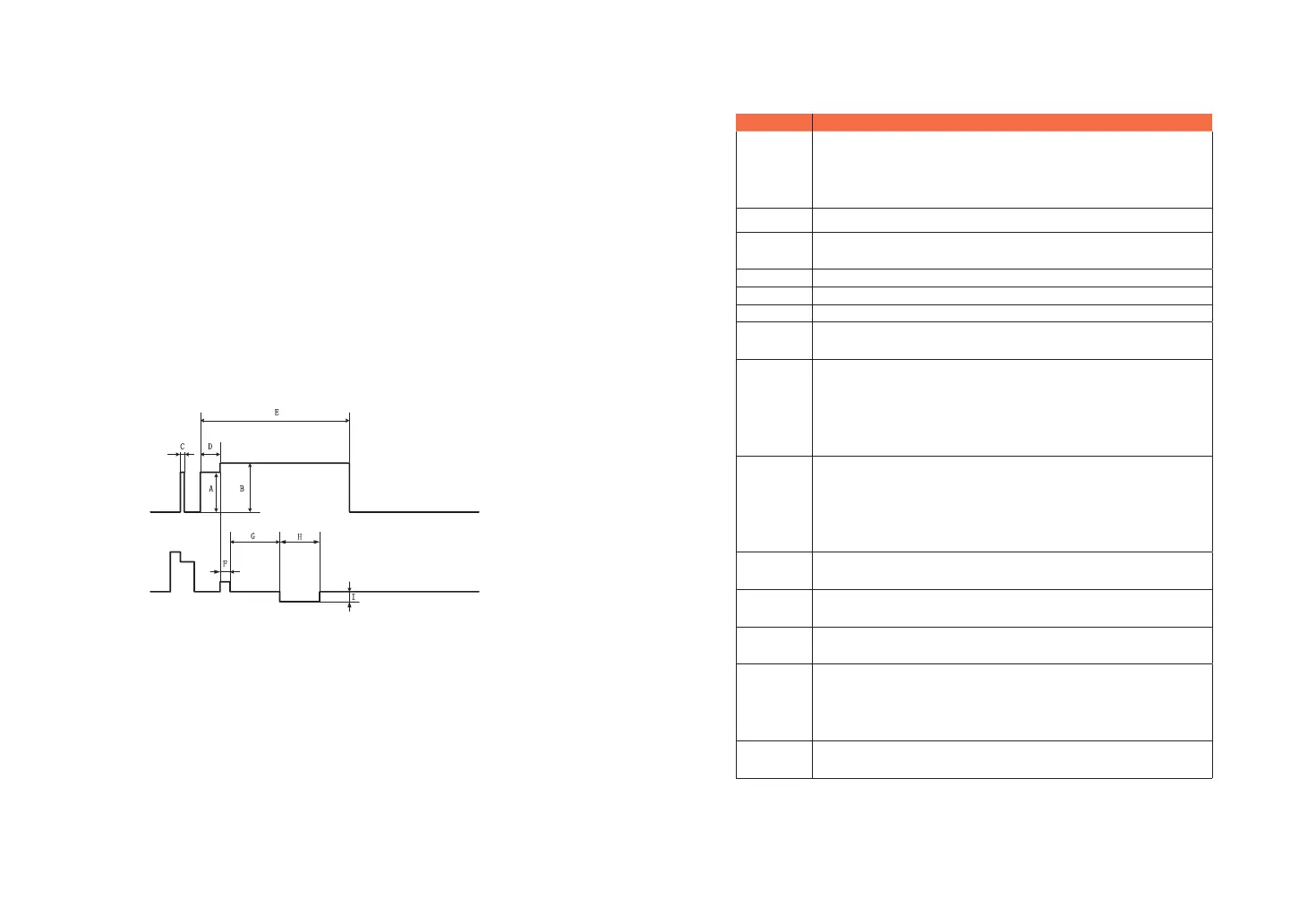

The following gure shows the discharge conditions (The relationship between the

“discharge intensity" and "motor move"). We can change the splicing parameters

listed below to change the discharge conditions.

A: Pre-fuse power B: Arc power C: Cleaning Arc

D: Pre-fuse time E: Arc time F: Overlap

G: Taper wait time H: Taper time related to taper length I: Taper speed

Diagram of ARC discharge condition

4.4 Parameters for Normal Splicing Process

Parameter Description

Template

A list of splice modes stored in the splicer database is displayed.

Upon inputting the appropriate mode, the selected splice mode

stored in database area is copied to a selected splice mode in user-

programmable area.

Name Title for a splice mode expressed in up to seven characters.

Note

Detailed explanation for a splice mode expressed in up to 15

characters. It is displayed at “Select splice mode” menu.

Focus-L Set the focus parameter for lens X.

Focus-R Set the focus parameter for lens Y.

Arc adjust Set to adjust arc power according to the bers’ conditions.

Pull test

If “Proof test” is set to “ON”, a pull-test is performed upon opening

the windproof cover or by pressing the SET button after splicing.

Loss

estimate

Loss estimate should be regarded as a reference. Since the loss is

calculated upon the ber image, there is certain dierence with the

real value. The estimate method is based on a single mode ber and

calculates at the wavelength of 1.31μm. The estimated value can be a

valuable reference, but cannot be used as the basis of acceptance.

Minimum

loss

This amount is added to the estimate splice loss originally calculated.

When splicing specially or dissimilar bers, a high actual splice loss

may occur even with optimized arc conditions. To make the actual

splice loss concur with the estimated splice loss, set the actual splice

loss to minimum value (minimum loss).

Loss Limit

An error message is displayed if the estimated splice loss exceeds

the selected threshold (loss limit).

Core angle

limit

An error message is displayed if the bend angle of the two bers

spliced exceeds the selected threshold (Core angle limit).

Cleave angle

limit

An error message is displayed if the cleave angle of either the left or

right ber ends exceed the selected threshold (cleave limit).

Gap position

Set the relative position of the splicing location to the center of

electrodes. Splice loss may be improved in the case of dissimilar

ber splicing by shifting [Gap position] towards a ber whose MFD is

bigger than the other ber MFD.

Gap

Set the end-face gap between the left and right bers at the time of

aligning and pre-fusion discharge.

Loading...

Loading...