2524

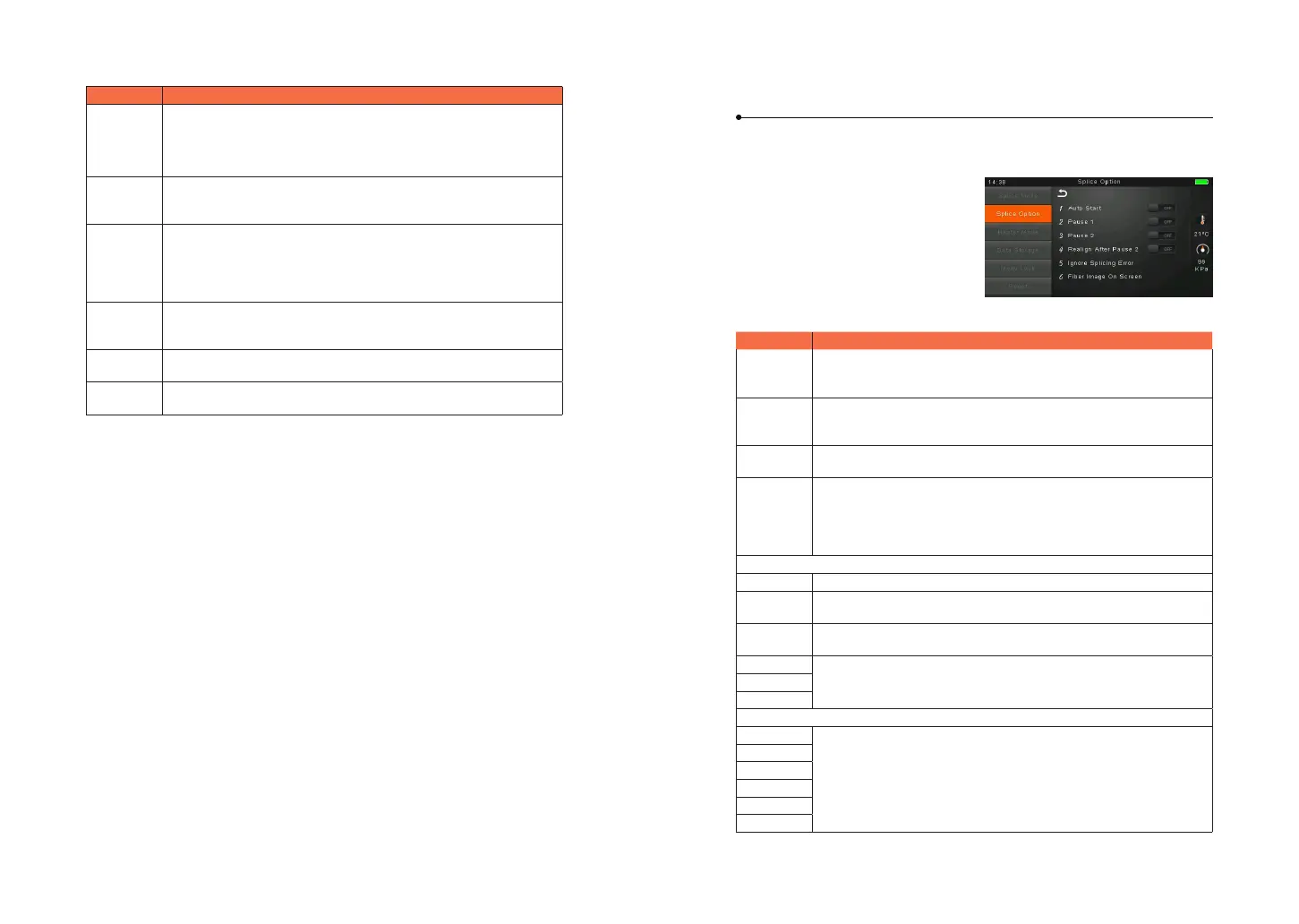

Chapter 5 Splice Option

As to the Splice Mode setting.

① Select [Splice option] in menu from

main menu.

② Select a parameter to be changed.

Parameter Description

Auto start

If “Auto start” is set to ON, splicing starts automatically as soon as

the wind protector is closed. Fibers should be prepared and placed

into the splicer in advance.

Pause 1

If “Pause 1” is set to ON, splicing operation pauses when bers are

forwarded to gap-set position. Cleave angles are displayed during

the pause.

Pause 2

If “Pause 2” is set to ON, splicing operation pauses after ber

alignment is completed.

Realign after

pause 2

Alignment failure may appear after “Pause2” for a long period.

Therefore, realign after “Pause2” is needed. Setting to “OFF” will

prevent the implementation of realign function. Manual splicing,

rather than setting the realign to “OFF”, is recommended when there

is an axial displacement of the splicer

Ignore splice error

Cleave end

Cleave

angle

Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Cleave Angle Error” appears.

Core angle

Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Core Angle Error” appears.

Loss

Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Loss Error”, “Cleave Shape Error”, “Fat

Error”, or “Thin Error” appears.

Fat

Thin

Fiber immage on screen

Paulse 1 Set the displaying method of the ber image on the screen during

splicing operation.

X : Enlarged display of X-axis image

Y : Enlarged display of Y-axis image

X/Y : Composite display vertically of X-axis and Y-axis images

Align

Paulse 2

Arc

Estimate

Gap set

Parameter Description

Overlape

Set the overlap amount of bers at the ber propelling stage.

Relatively small [Overlap] is recommended if [Preheat Arc Value] is

low, while relatively large [Overlap] is recommended if [Preheat Arc

Value] is high.

Cleaning Arc

time

A cleaning arc burns out micro dust on the surface of the ber with

an arc discharge for a short period of time. The duration of the

cleaning arc can be changed by this parameter.

Preheat Arc

value

Set the pre-fuse arc power from the beginning of arc discharging

to the beginning of bers propelling. If “Preheat Arc Value” is set

too low, axial oset may occur if cleaved angles are relatively poor.

If “Preheat Arc Value” is set too high, ber end faces are fused

excessively and splice loss gets worse.

Preheat Arc

time

Set the pre-fuse arc time from the beginning of arc discharging to

the beginning of bers propelling. Long [Preheat Arc Time] and high

[Preheat Arc Value] lead to the same results.

Fuse Arc

value

Set Arc power.

Fuse Arc

time

Set Arc time.

Loading...

Loading...