35

®

VALVE PROVING

The BurnerPRO offers an intelligent Valve Proving System (VPS). It checks the effective closure of auto-

matic shut-off valves by measuring the pressure differential between two fuel shutoff valves during the test

sequence. When active, it will open and close the main safety shutoff valves (double block valve arrange-

ment) in the proper sequence and monitor the pressure in the gas pipe between the two safety shutoff valves

(MV1 & MV2).

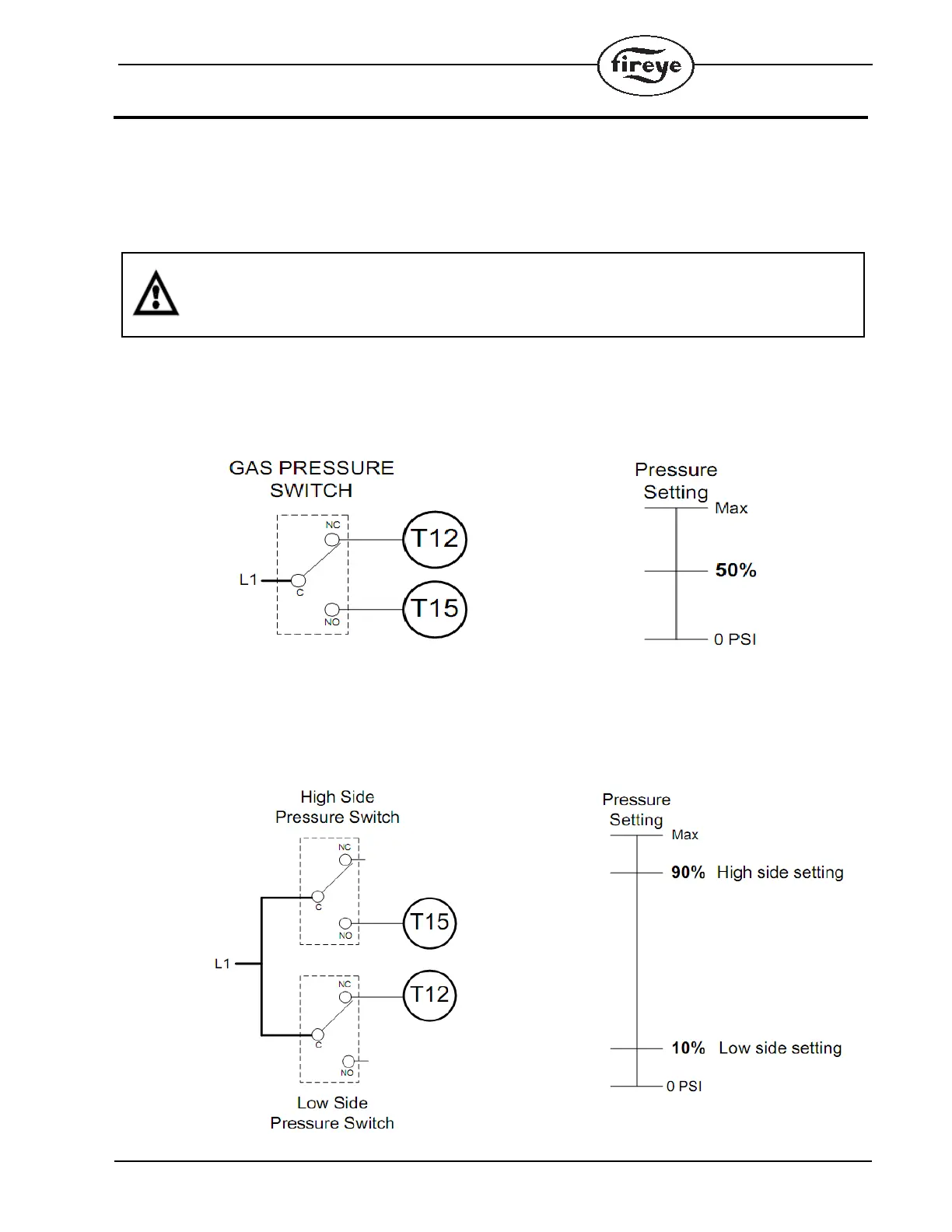

The gas pressure sensing device, pressure switch, is recommended to be installed between the two shutoff

valves. The two common methods of pressure switch setup are described below:

Method 1: A single pressure switch installed between the shutoff valves.

This setup requires that the gas pressure switch be adjusted to ½ the gas train pressure. The rule of operation

is quite simple: The pressure switch will "make" (DI2 high) when gas pressure in the test section exceeds the

set pressure; it will "break" (DI1 high) when the gas pressure falls below the set pressure.

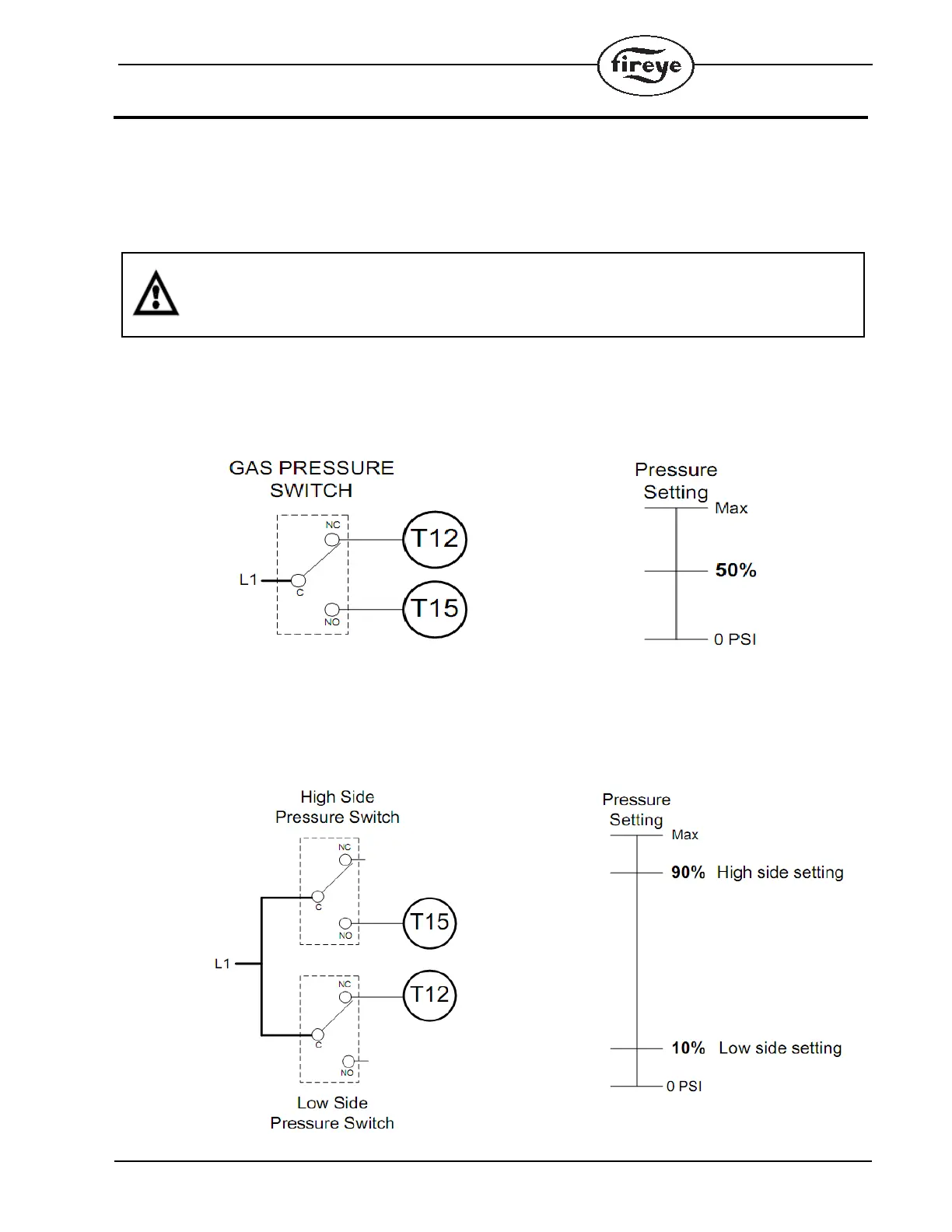

Method 2: Dual pressure switches installed between the shutoff valves.

WARNING: It is the responsibility of the installing and operating personnel to ensure that the valve prov-

ing system is properly installed and configured. The appropriate permissible leakage rate information

should be used when setting up a valve proving system. Please consult the burner manufacturer and/or

applicable codes, ordinances, and regulations.

Loading...

Loading...