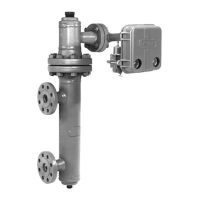

Type 2500

14

Table

4. Recommended Settings For Pre-Startup Checks

RECOMMENDED RAISE LEVEL SETTING

FOR TYPE 2500 CONTROLLER

RECOMMENDED ZERO ADJUSTMENT SETTING FOR

TYPE 2500T TRANSMITTER

MOUNTING ACTION

For Predetermined

PROPORTIONAL BAND

Dial Setting of 10

For Predetermined

PROPORTIONAL BAND

Dial Setting of 0

For Predetermined

SPECIFIC GRAVITY Dial

Setting of 1.0

For Predetermined

SPECIFIC GRAVITY Dial

Setting of 0

-

Direct 3.0 to 3.5 4.0 to 4.5 1.5 to 2.0 to right 0.5 to 1.0 to right

Right-hand

Reverse 6.5 to 7.0 0.5 to 1.0 1.5 to 2.0 to left 4.0 to 4.5 to right

-

Direct 3.0 to 3.5 4.0 to 4.5 1.5 to 2.0 to left 0.5 to 1.0 to left

Left-hand

Reverse 6.5 to 7.0 0.5 to 1.0 1.5 to 2.0 to right 4.0 to 4.5 to left

1. For proportional band dial settings between 10 and 0 or for specific

gravity dial settings between 1.0 and 0, interpolate the value.

Note

Adjustment of the RAISE LEVEL control

can set the switching points anywhere

within the length of the displacer. Be

careful not to set the switching points

so that one is off the displacer.

4. Make sure that the PROPORTIONAL BAND con-

trol is at the setting determined in the previous proce-

dures. Set the RAISE LEVEL control to 0, then set it

to 1.0 for a direct-acting or 4.0 for a reverse-acting

controller.

5. The OUTPUT gauge should read 0 psig (0 bar) for

direct or supply pressure for reverse action.

6. Increase the process variable until the OUTPUT

gauge changes to either supply pressure for direct or 0

psig (0 bar) for reverse acting. The process variable

should be at the desired high trip value. On a control-

ler with an indicator assembly, the pointer should be

over the HIGH point on the indicator plate; slight ad-

justment may be necessary, as described at the end

of step 3.

7. Decrease the process variable until the OUTPUT

gauge changes to 0 psig for direct or supply pressure

for reverse action (depending on controller range). The

process variable should be at the desired low trip val-

ue.

8. If all prestartup checks are satisfactory, proceed to

the Startup section. If performance is unsatisfactory,

proceed to the Calibration section.

Type 2503 Controller

Note

In the following steps the output pres-

sure can go as high as the controller

supply pressure.

Note

Since the Type 2503 controller has no

proportional valve, the differential gap

between switching points is adjusted by

varying the supply pressure. This gap

can be varied from approximately a

3.5-inch (88.9 mm) level change at 15

psig (1 bar) to a 6.0-inch level change at

25 psig (1.7 bar) with a standard volume

displacer and a fluid with a specific

gravity of 1.0. The gap also varies in-

versely according to density; a fluid

with 0.8 specific gravity produces a

4.4-inch (112 mm) level change at 15

psig to a 7.5-inch change at 25 psig (1.7

bar). Set the gap at a pressure low

enough to be compatible with the limita-

tions of the diaphragm control valve or

other final control element.

1. Turn on the supply pressure. If necessary, adjust

the Type 67FR regulator to produce the desired differ-

ential gap by loosening the locknut (figure 11) and

turning the adjusting screw clockwise to increase or

counterclockwise to decrease pressure. Tighten the

locknut.

2. Locate the process variable at its minimum value.

Note

Adjustment of the RAISE LEVEL control

can set the switching points anywhere

within the length of the displacer. Be

careful not to set the switching points

so that one is off the displacer.

3. Set the RAISE LEVEL control to 0 and then reset it

as follows:

a. For direct-acting controllers, set it between 1.0

and 1.5.

b. For reverse-acting controllers, set it between 3.5

and 4.0.

4. The OUTPUT gauge should read 0 psig (0 bar) for

direct or full supply pressure for reverse action.

Loading...

Loading...