Type 2500

8

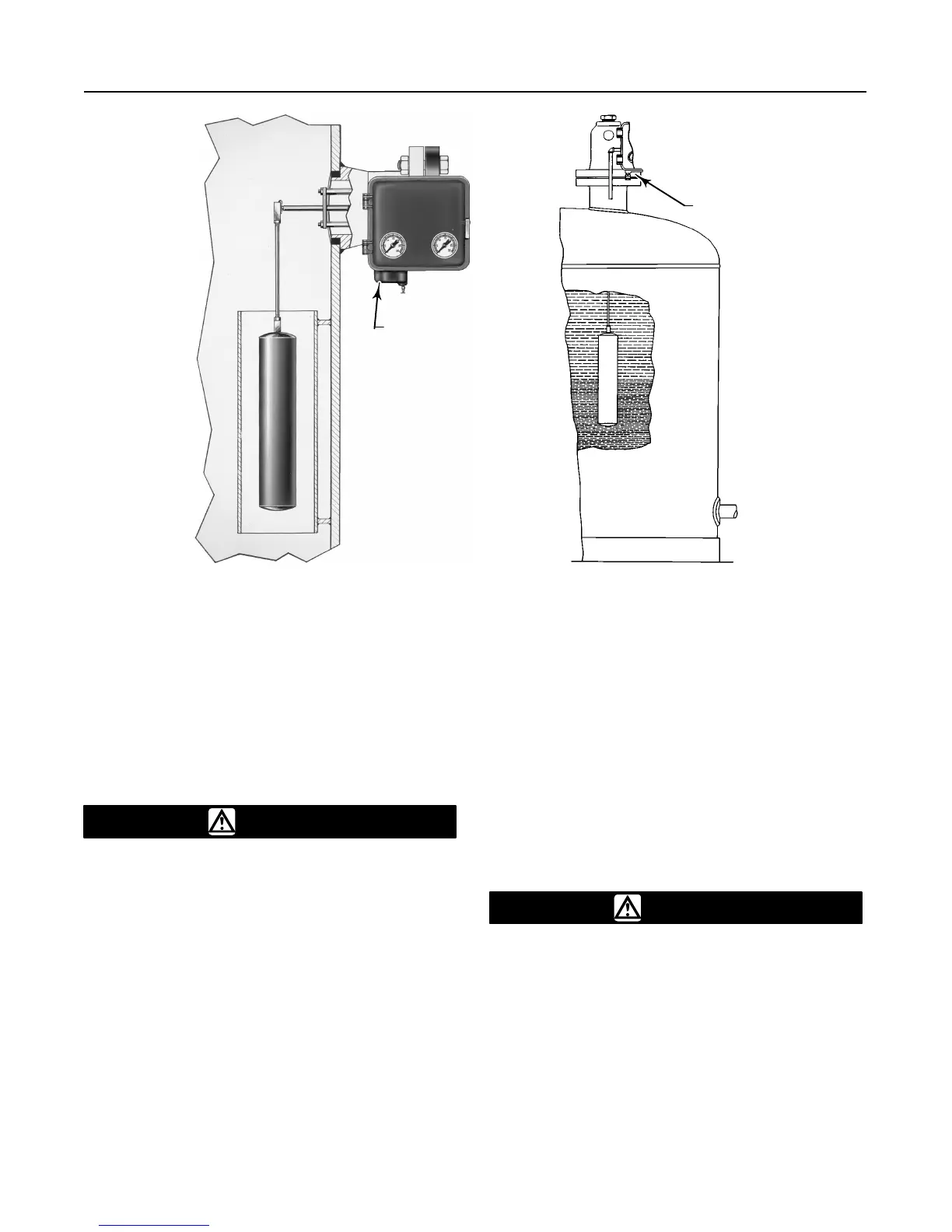

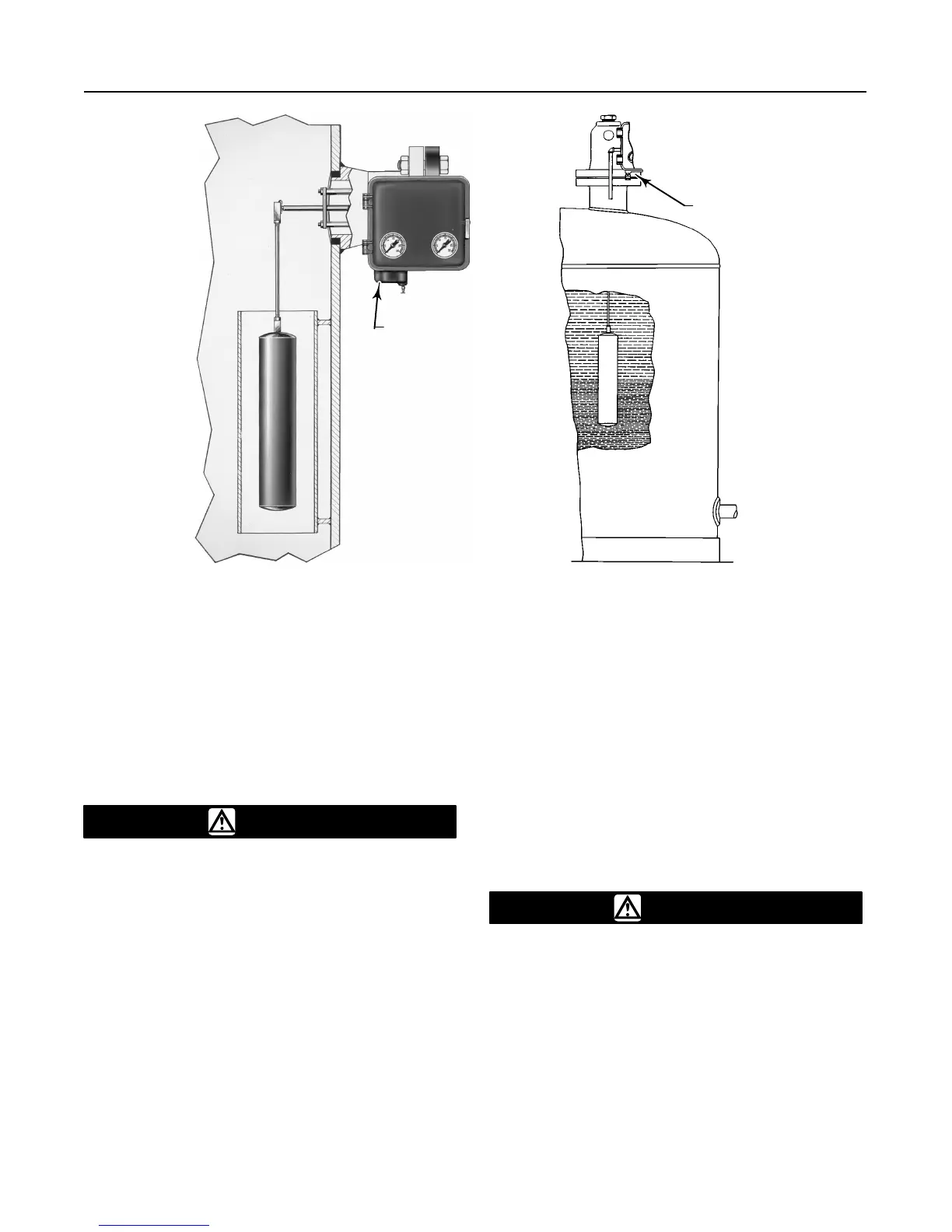

Figure

7. Cageless Sensor Mounting

CF5380-A

A3893/IL

TOP

MOUNTED

SIDE

MOUNTED

W0645–1/IL

If an extension is used between the displacer spud

and the displacer stem end piece, make sure the nuts

are tight at each end of the displacer stem extension.

Install and tighten suitable bolting or cap screws in the

flanged connection to complete the installation.

Top-Mounted Sensor

CAUTION

If inserting the displacer into the vessel

before attaching to the displacer rod,

provide a means of supporting the dis-

placer to prevent it from dropping into

the vessel and suffering damage.

Figure 7 shows an example of a top-mounted cage-

less sensor. You may attach the displacer to the dis-

placer rod before installing the sensor on the vessel. If

the displacer diameter is small enough, you may de-

sire to install a long or sectionalized displacer through

the sensor head access hole after the sensor is

installed on the vessel. Connect the displacer as

shown in figure 8, locking the assembly with the cotter

springs provided. If a stem extension is used between

the displacer spud and the stem end piece, make sure

the nuts are tight at each end of the stem. Install and

tighten suitable cap screws in the flanged connection

to complete the installation.

A special travel stop may be provided on top-mounted

sensors to aid in servicing of the sensor. This option

prevents dropping the displacer and stem when the

displacer rod is disconnected

Special Installations

Temperature-Compensated Displacer

CAUTION

The bellows style temperature compen-

sating displacers are relatively fragile

and must be protected from all physical

damage.

Some sensor assemblies use a temperature-compen-

sated displacer shown in figure 9. This displacer is

appropriate only for density applications that measure

fluid composition regardless of temperature. The dis-

placer must be filled completely with the fluid to be

measured, or with a fluid of equal volumetric expan-

Loading...

Loading...