Type 2500

6

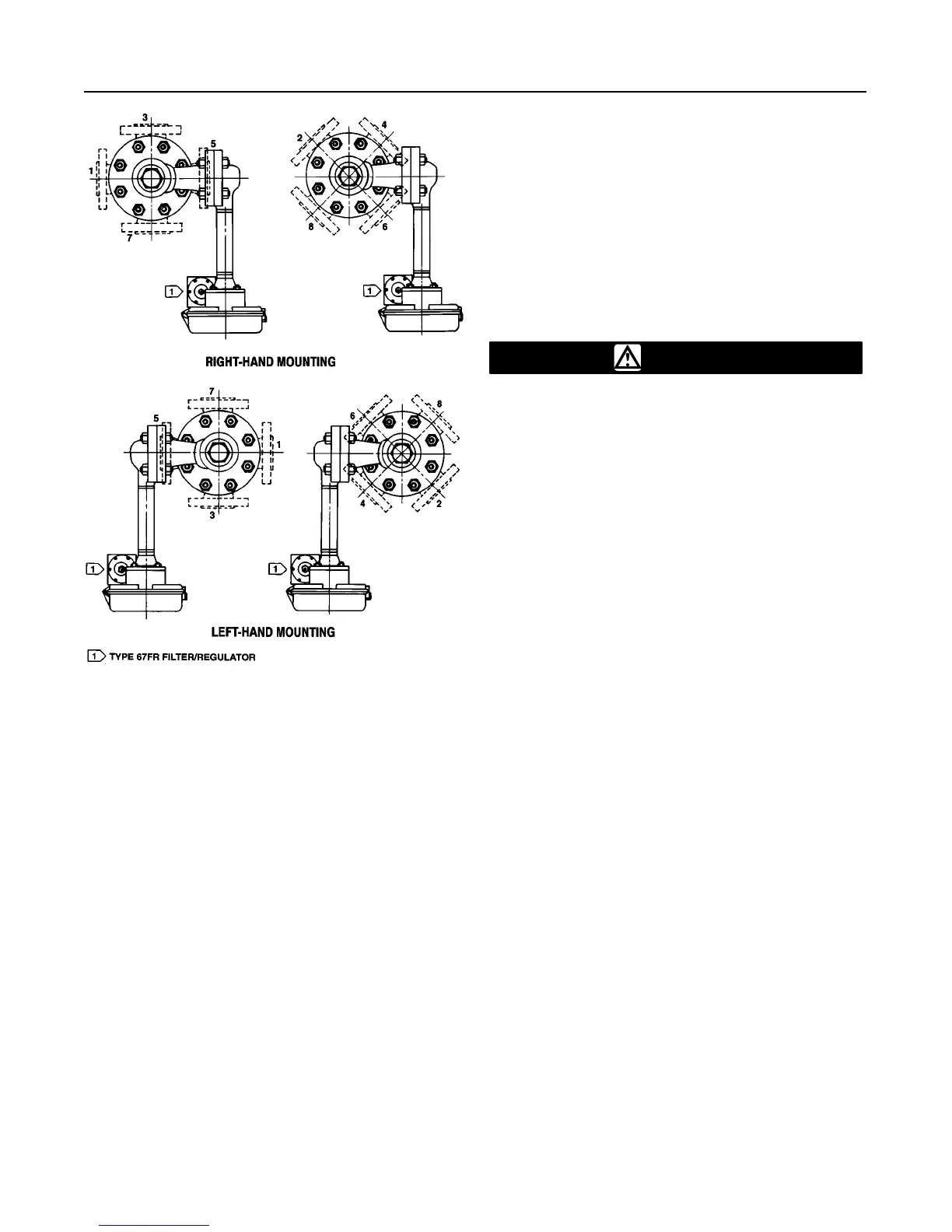

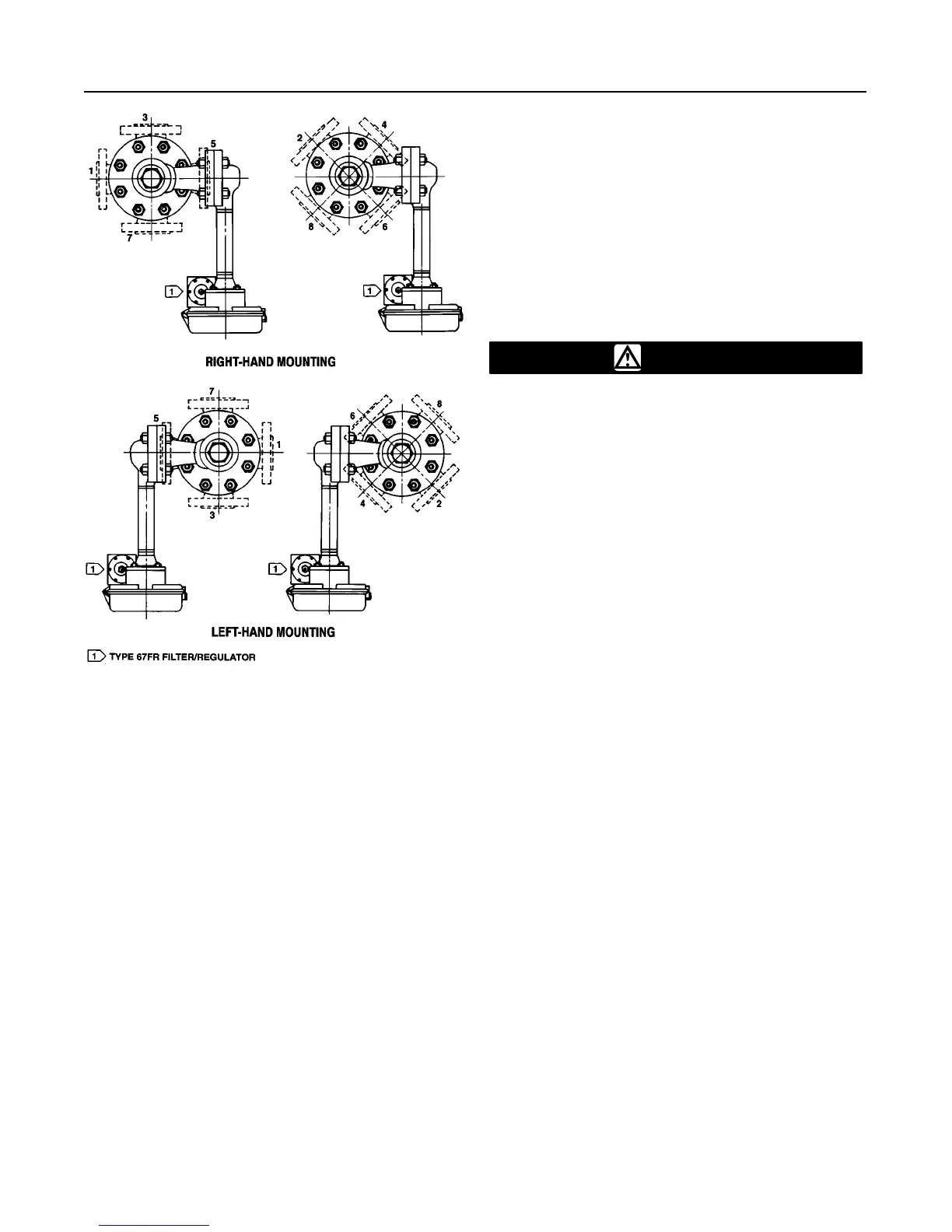

Figure

4. Cage Head Mounting Positions

AH9150–A

A2613–1/IL

A cageless sensor comes with its displacer separated

from the sensor assembly. Displacers longer than 32

inches (813 mm) come in a separate crate. Shorter

displacers come in the same crate as the sensor, but

are not attached to their displacer rods. Inspect the

displacer to insure it is not dented. A dent may reduce

the pressure rating of the displacer. If a displacer is

dented, replace it.

Controller/Transmitter Orientation

The controller/transmitter attaches to the sensor in

one of the mounting positions shown in figure 4. Right

hand mounting is with the controller or transmitter

case to the right of the displacer when you look at the

front of the case; left hand mounting is with the case

to the left of the displacer. The mounting position can

be changed in the field. Changing this mounting posi-

tion changes the control action from direct to reverse,

or vice versa.

All caged sensors have a rotatable head. That is, the

controller/transmitter may be positioned at any of eight

alternate positions around the cage as indicated by the

numbers 1 through 8 in figure 4. To rotate the head,

remove the head flange bolts and nuts and position

the head as desired.

Mounting Caged Sensor

CAUTION

Install the cage so that it is plumb; the

displacer must not touch the cage wall.

If the displacer touches the cage wall,

the unit will transmit an erroneous out-

put signal.

Note

If the controller/transmitter is not

mounted on the sensor, refer to the

Installing Controller/Transmitter on Sen-

sor procedures in the Maintenance sec-

tion. That section also provides instruc-

tions for adding a heat insulator to a

unit.

If a temperature-compensated displacer

or piezometer ring is used, refer to the

Special Installation procedures in this

section before proceeding.

Cage connections normally are either 1-1/2 or 2-inch,

screwed or flanged. Figure 5 shows the combinations.

With flanged connections, use standard gaskets or

other flat-sheet gaskets compatible with the process

fluid. Spiral-wound gaskets without compression-con-

trolling centering rings cannot be used for flange con-

nections.

As shown in figure 6, mount the cage by running

equalizing lines between the cage connections and the

vessel. A shutoff or hand valve with a 1-1/2 inch diam-

eter or larger port should be installed in each of the

equalizing lines. Also install a drain between the cage

and shutoff or hand valve whenever the bottom cage

line has a fluid-trapping low point.

On fluid or interface level applications, position the

sensor so that the center line on the cage (see figure

6) is as close as possible to the center of the fluid level

or interface level range being measured. Also consider

installing a gauge glass on the vessel, or on the sen-

sor cage (if the cage is tapped for a gauge).

Loading...

Loading...