Type 2500

5

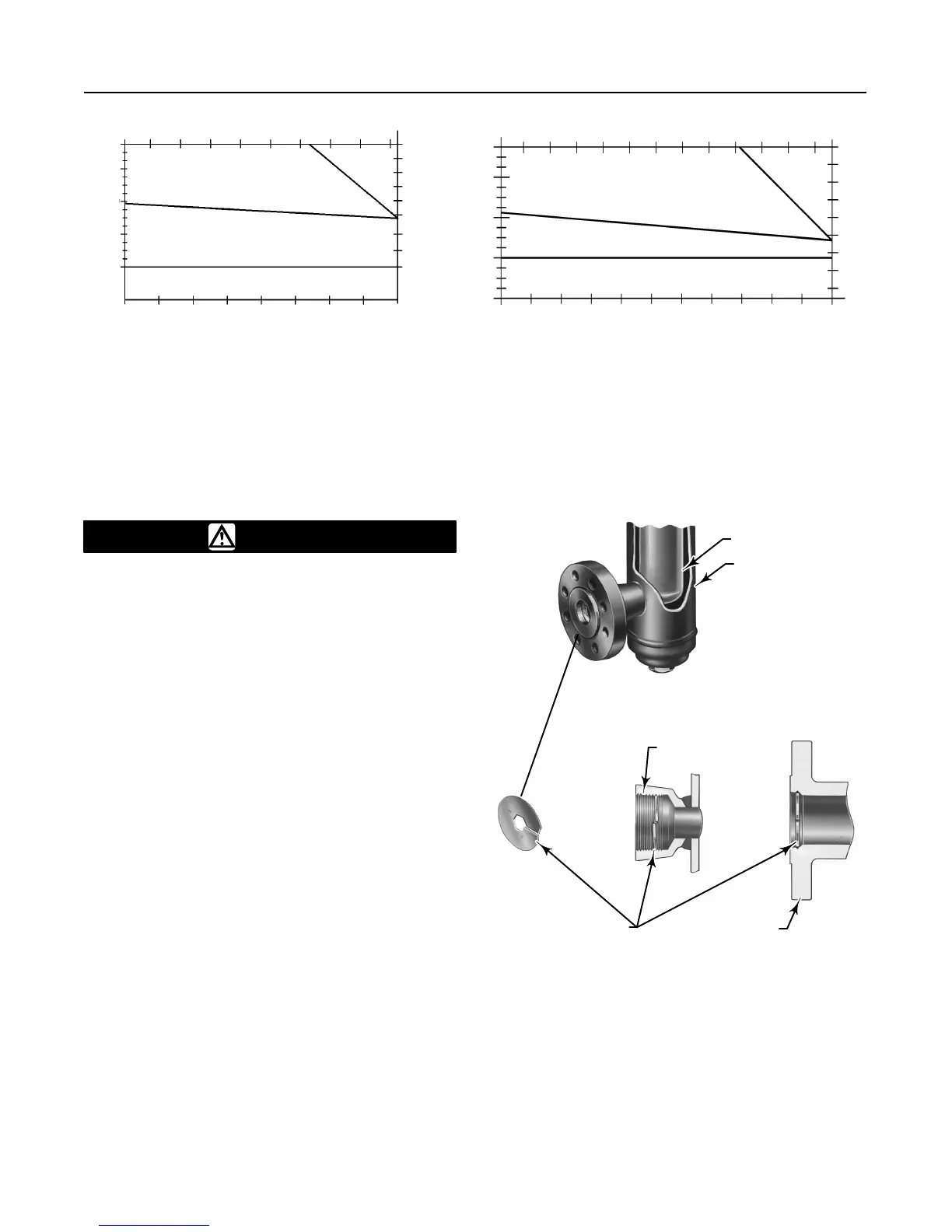

Figure 2. Guidelines for Use of Optional Heat Insulator Assembly

0 20 40 60 80 100 120 140 160

USE INSULATOR (CAUTION! IF AMBIENT DEWPOINT IS ABOVE

PROCESS TEMPERATURE, ICE FORMATION MAY CAUSE IN-

STRUMENT MALFUNCTION AND REDUCE INSULATOR EFFECTIVE-

NESS.)

01020

–18

–10

30 40 50 60 70

71

593

500

400

300

200

100

–40

0

400

800

1100

–20

NO INSULATOR NECESSARY

AMBIENT TEMPERATURE (C)

AMBIENT TEMPERATURE (F)

HEAT INSULATOR

REQUIRED

TOO

HOT

NOTE:

FOR APPLICATIONS BELOW –20F (–29C), BE SURE THE SENSOR

MATERIALS OF CONSTRUCTION ARE APPROPRIATE FOR THE SERVICE

TEMPERATURE.

PROCESS TEMPERATURE ( C)

PROCESS TEMPERATURE ( F)

0 20 40 60 80 100 120 140 200

0

10 20

–18

–10

30 40 50 60 70

105

593

500

400

300

200

100

0

0

400

800

1100

–20

NO INSULATOR NECESSARY

AMBIENT TEMPERATURE (C)

AMBIENT TEMPERATURE (F)

HEAT INSULATOR

REQUIRED

TOO

HOT

PROCESS TEMPERATURE ( C)

PROCESS TEMPERATURE ( F)

180160

80 90

USE INSULATOR (CAUTION! IF AMBIENT DEWPOINT IS ABOVE PROCESS

TEMPERATURE, ICE FORMATION MAY CAUSE INSTRUMENT MALFUNCTION

AND REDUCE INSULATOR EFFECTIVENESS.)

CV6190–E

B1413-2/IL

–40

–29

–18

100

220

CAUTION

Sensors used for interface or density

control may be so large and heavy that

the torque tube cannot fully support

their weight in air. On the 249V, a travel

stop is used to prevent damage. Do not

remove this travel stop assembly with-

out first removing the displacer from the

displacer rod. Refer to the instruction

manual for cageless 249 Series sensors.

Note

Caged sensors have rods and blocks

installed at each end of the displacers to

protect the displacers in shipping. Re-

move these parts before you install the

sensor to allow the displacer to function

properly.

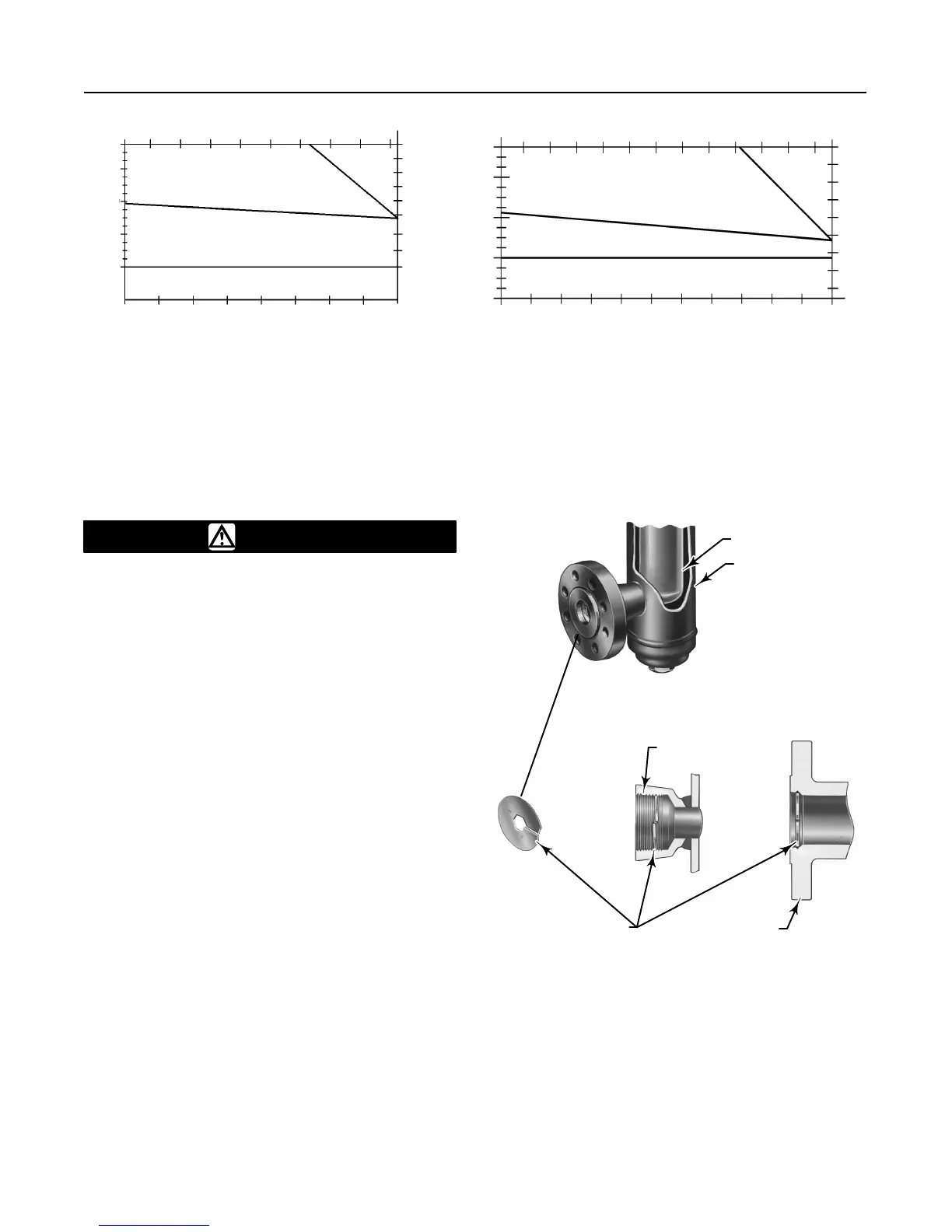

Caged sensors come with the displacer installed in the

cage. If a tubular gauge glass is ordered with the sen-

sor, the gauge glass is crated separately and must be

installed at the site. A damping plate is installed in the

lower screwed or flanged connection (see figure 3) to

provide more stable operation. Be certain that the

cage equalizing connections and the damping plate

are not plugged by foreign material.

Figure

3. Damping Plate Location

W0144–1/IL

W2141–1B/IL

DISPLACER

CAGE

SCREWED

CONNECTION

FLANGED

CONNECTION

DAMPING PLATE

Loading...

Loading...