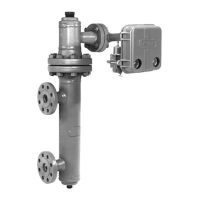

Type 2500

19

Note

If you cannot calibrate the controller or

transmitter, look for other problems as

described in the Troubleshooting proce-

dures, such as leaking connections, or a

binding displacer rod. If none of these

troubles are apparent, ensure that the

displacer is sized correctly for the ap-

plication.

Type 2500S and 2503 Controllers

1. Turn on the supply pressure and check that it is set

according to the appropriate prestartup checks proce-

dure.

2. Make sure that the PROPORTIONAL BAND ad-

justment (Type 2500S only) is at the setting deter-

mined according to the appropriate prestartup check

procedure.

3. Perform one or the other of the following:

For direct acting controllers, set the RAISE

LEVEL adjustment between 1.0 and 1.5.

For reverse acting controllers, set the RAISE

LEVEL adjustment between 3.5 and 4.0.

4. Set the process variable at the minimum value of

the input range as shown in table 5. For constructions

with an indicator assembly, make sure that the pointer

is over the LOW mark.

Note

In the following step, the alignment

screw (key 33, figure 19) always must

remain screwed in far enough to provide

spring tension on the underside of the

alignment screw head.

5. Be sure the flapper is centered over the nozzle. If

not, loosen the hex nut (key 40, figure 19) and reposi-

tion the flapper, tighten the hex nut.

6. Adjust the flapper (key 32, figure 19) as described

below. For coarse flapper adjustment, loosen the hex

nut (key 40, figure 19) and rotate the flapper assembly

about the torque tube shaft. For fine flapper adjust-

ment, turn the flapper alignment screw (key 33, figure

19).

For Direct Acting Controllers, move the flapper

toward the nozzle until the output pressure switches to

full supply pressure, then carefully adjust the flapper

away from the nozzle until the output pressure

switches to 0 psig.

For Reverse Acting Controllers, move the flap-

per away from the nozzle until the output pressure

switches to 0 psig, then carefully adjust the flapper

toward the nozzle until the output pressure switches to

full supply pressure.

7. Slowly increase the process variable until the out-

put pressure switches:

For Direct Acting Controllers, slowly increase

the process variable until the output pressure switches

to full supply pressure. The process variable should be

at the maximum value of input range as shown in table

5. If the process variable agrees with table 5, proceed

with step 8. If the process variable does not agree with

table 5, proceed to step 9.

For Reverse Acting Controllers, slowly in-

crease the process variable until the output pressure

switches to 0 psig. The process variable should be at

the maximum value of input range as shown in table 5.

If the process variable agrees with table 5, proceed

with step 8. If the process variable does not agree with

table 5, proceed to step 9.

8. If the unit does not contain an indicator assembly,

go to the startup section. If the unit contains an indica-

tor assembly, change the pointer span by loosening

the indicator plate screws (key 41, figure 19, indicator

assembly detail), slide the plate until the HIGH mark is

under the pointer. Tighten the plate screws and go to

the startup section.

Note

Any sliding of the level set arm (key 28,

figure 19) in the following step changes

the zero as well as the differential gap.

9. To adjust the differential gap, loosen the two level

set mounting screws (see figure 19) and slide the flex-

ure strip base (key 27) right or left along the elongated

slotted hole as follows:

To decrease the differential gap, slide the flexure

strip base away from the torque tube shaft.

To increase the differential gap, slide the flexure

strip base toward the torque tube shaft.

Retighten the screws. For the Type 2500S only, if the

flexure strip base has been moved as far as possible

and the differential gap is still too low, proceed to

step 11.

10. Repeat the procedure from step 4 until the re-

quired calibration points are obtained.

Loading...

Loading...