Type 2500

9

W0229-1A/IL

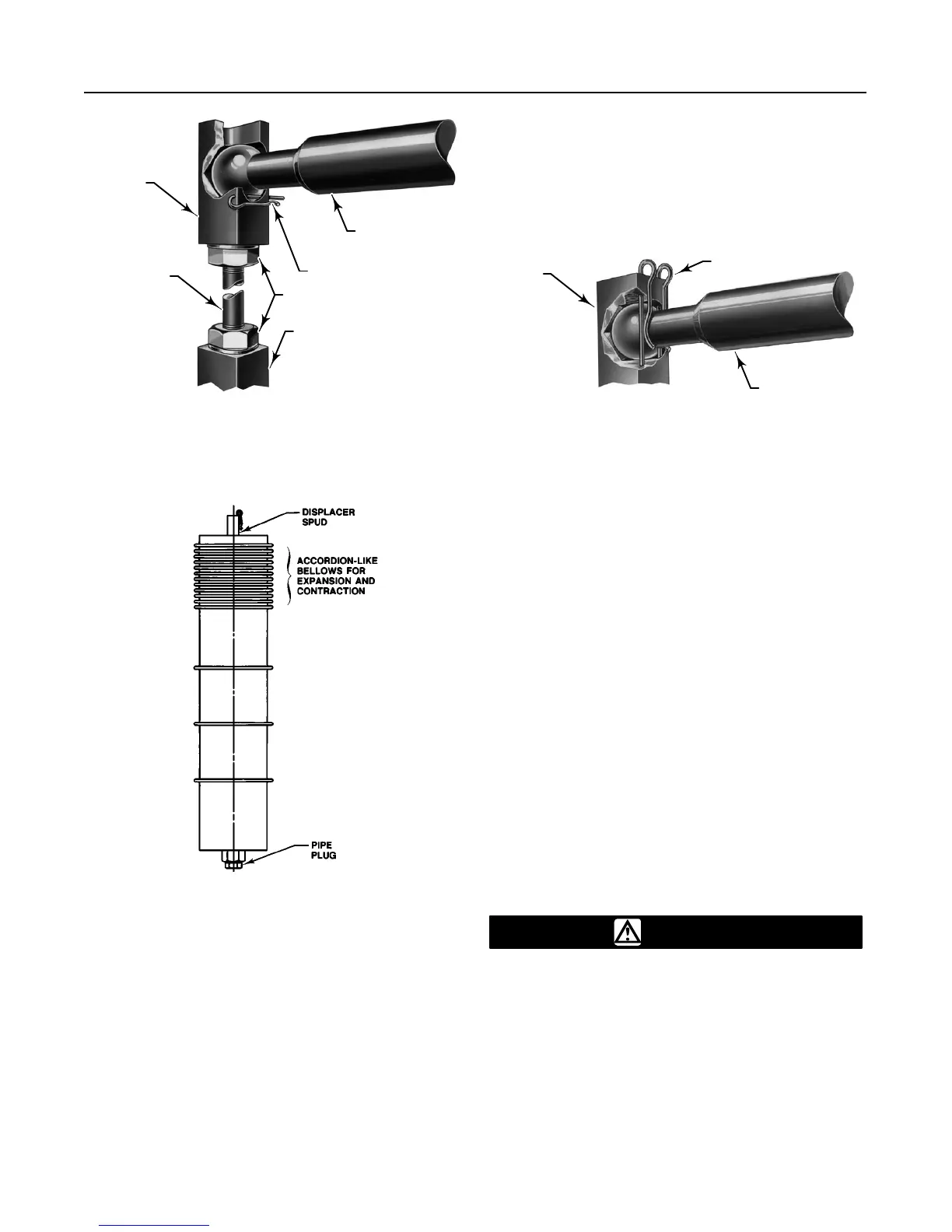

COTTER SPRING

DISPLACER ROD

LOCKING NUTS

DISPLACER SPUD

DISPLACER

STEM

EXTENSION

DISPLACER

STEM

END PIECE

W0228-1A/IL

DISPLACER ROD

DISPLACER

SPUD

COTTER SPRING

Figure

8. Displacer and Displacer Rod Connections

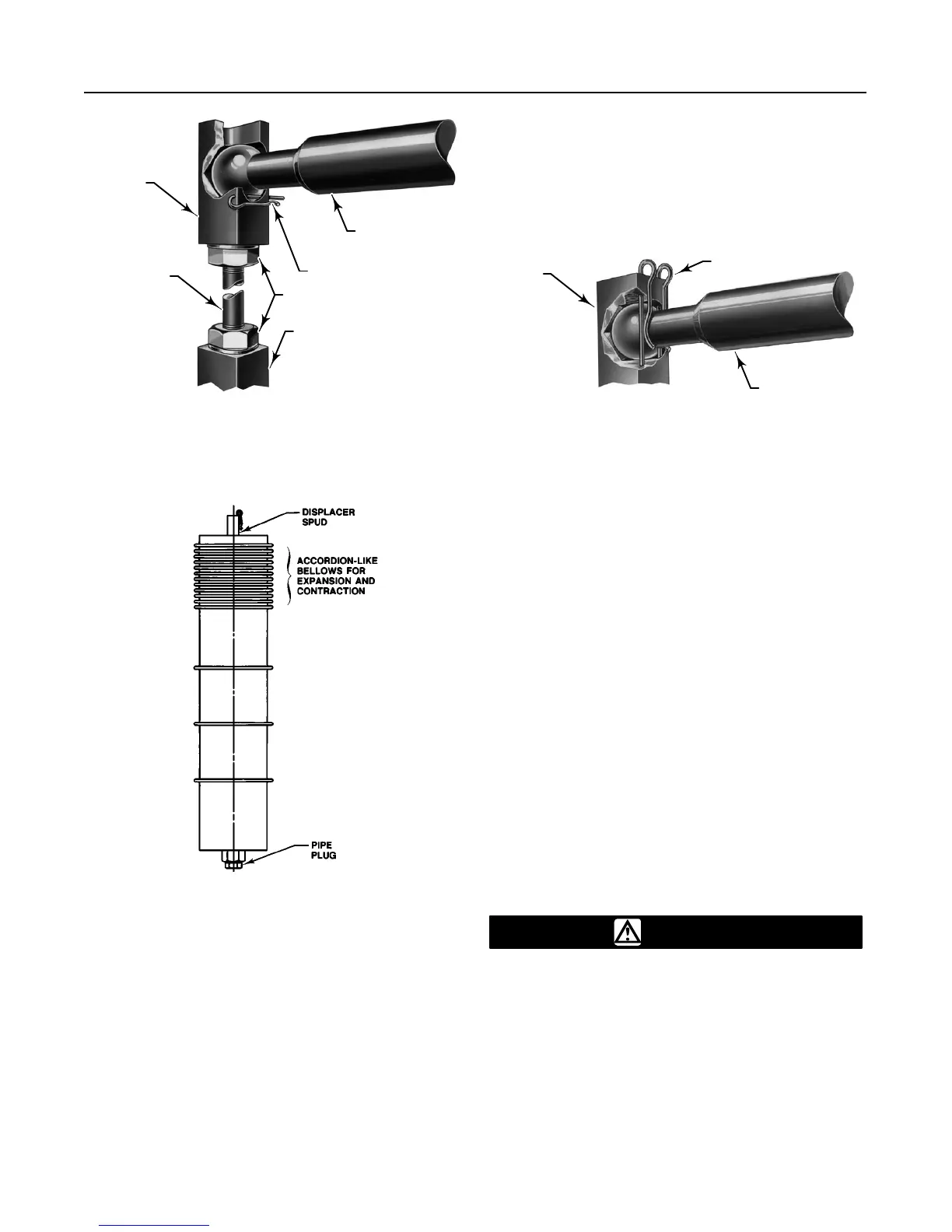

Figure 9. Temperature-Compensated Displacer

A0746–1/IL

sion coefficient. In service, the displacer expands and

contracts the same amount as the measured fluid to

nullify signal changes that would be caused by tem-

perature changes.

This type of displacer comes in a separate carton, but

is in the same crate as the rest of the assembly. See

the appropriate sensor manual for displacer filling

instructions.

Piezometer Ring

A piezometer ring, shown in figure 10, is used when

measuring the specific gravity of a flowing fluid in a

line. The piezometer ring reduces the velocity effects

caused by fluid passing through the displacer cage.

However, the fluid velocity through the cage should

not exceed two feet per minute (10 mm/second).

To install this type of sensor, connect a line to the

cage inlet and outlet piping at each end of the cage.

Use hand valves to balance the fluid flow through the

cage and keep the displacer cage filled. Provide a

rotameter or sight flow gauge for measuring velocity

through the cage. If the flow rates are properly bal-

anced, the transmitter output shows little change when

flow through the cage is shut off. If the flow rate

through the cage is too high, the turbulence may

cause an erratic output pressure signal. Readjust the

hand valves to stabilize the output pressure signal.

Supply and Output Pressure

Connections

WARNING

To avoid personal injury or property

damage resulting from the sudden re-

lease of pressure, do not install any sys-

tem component where service condi-

tions could exceed the limits given in

this manual. Use pressure-relieving de-

vices as required by government or ac-

cepted industry codes and good engi-

neering practices.

Loading...

Loading...