27

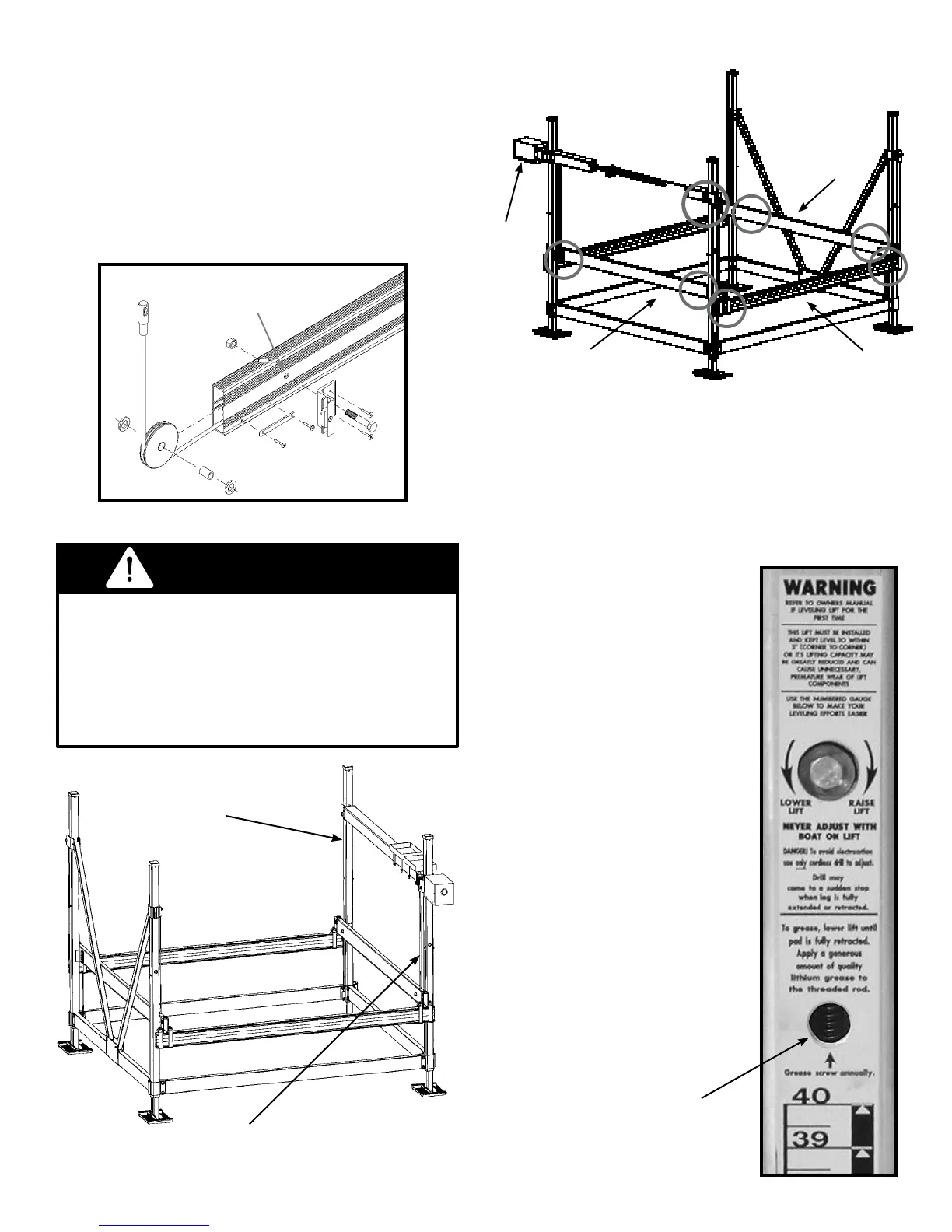

SIDE CRADLE LIFT BEAM PULLEYS

The side cradle lift beam pulley, which is a little

more difcult to access can be seen in Fig. 69.

It can still be checked from the open end of the

beam by using a long pry bar or at screwdriver

and pushing against the side of the top and bot-

tom of the pulley to test for excessive side-to-side

play (See Fig. 68)

Fig 70

Circles indicate pulley locations

Side Cradle

Lift Beam

Main Cradle Lift Beam

Side Cradle

Lift Beam

Drive

Train

Box

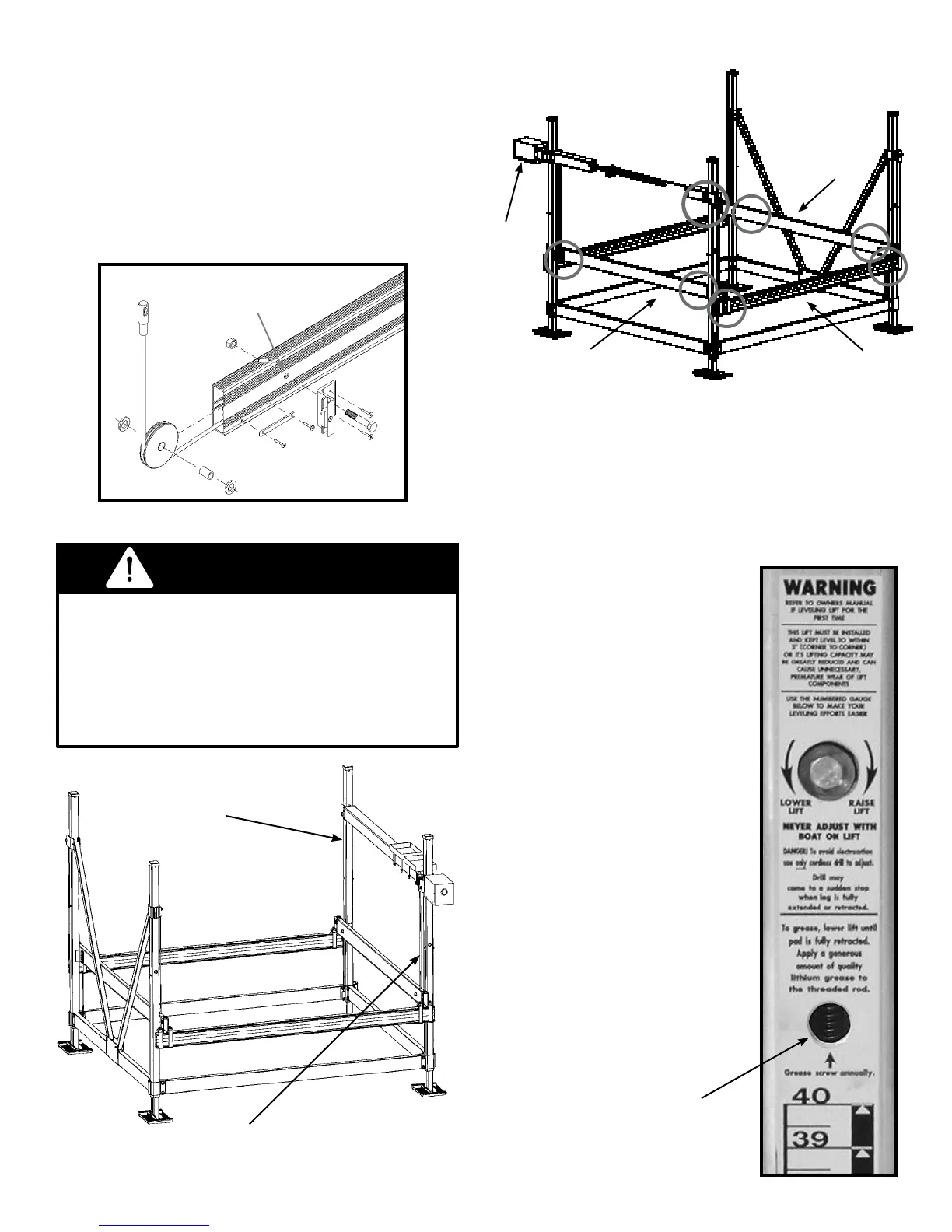

Grease Ball-Screw Annually

Fig 71

Grease Easy-Level Leveling Legs Annually

(one on each corner post, for a total of four)

GREASE HOLE

Fig 72

Loose fasteners can cause instability in the

lift frame resulting in premature wear to the

lift structure and create a structurally unsafe

boat lift. Damage due to loose fasteners or

improper assembly and/or maintenance will

void warranty .

WARNING

Fig 69

Location of bolt (pin) for side

cradle lift beam pulley

Fig. 70 Location of Sheaves

There is one pulley in the corner post opposite the drive

train box, one at each end of the two side cradle lift beams,

and one at each end of the front cradle lift beam. Total of

seven pulleys.

GREASING THE EASY-LEVEL

LEVELING LEG

The Easy-Level leveling leg

must be greased at least once

annually. This should be done

prior to winter storage if the

lift is removed seasonally. To

grease, lower lift until the pad

is fully retracted and the ac-

cess holes line up, with the

threaded rod clearly visible

inside the hole. Apply a

generous amount of quality

lithium grease to the threaded

rod as shown in Fig. 72.

Remember to grease all

four legs and extend them to

distribute the grease.

Refer to pages 11-12 for more

information and tips on using

the leveling legs.

Loading...

Loading...