28

GREASING THE BALL-SCREW

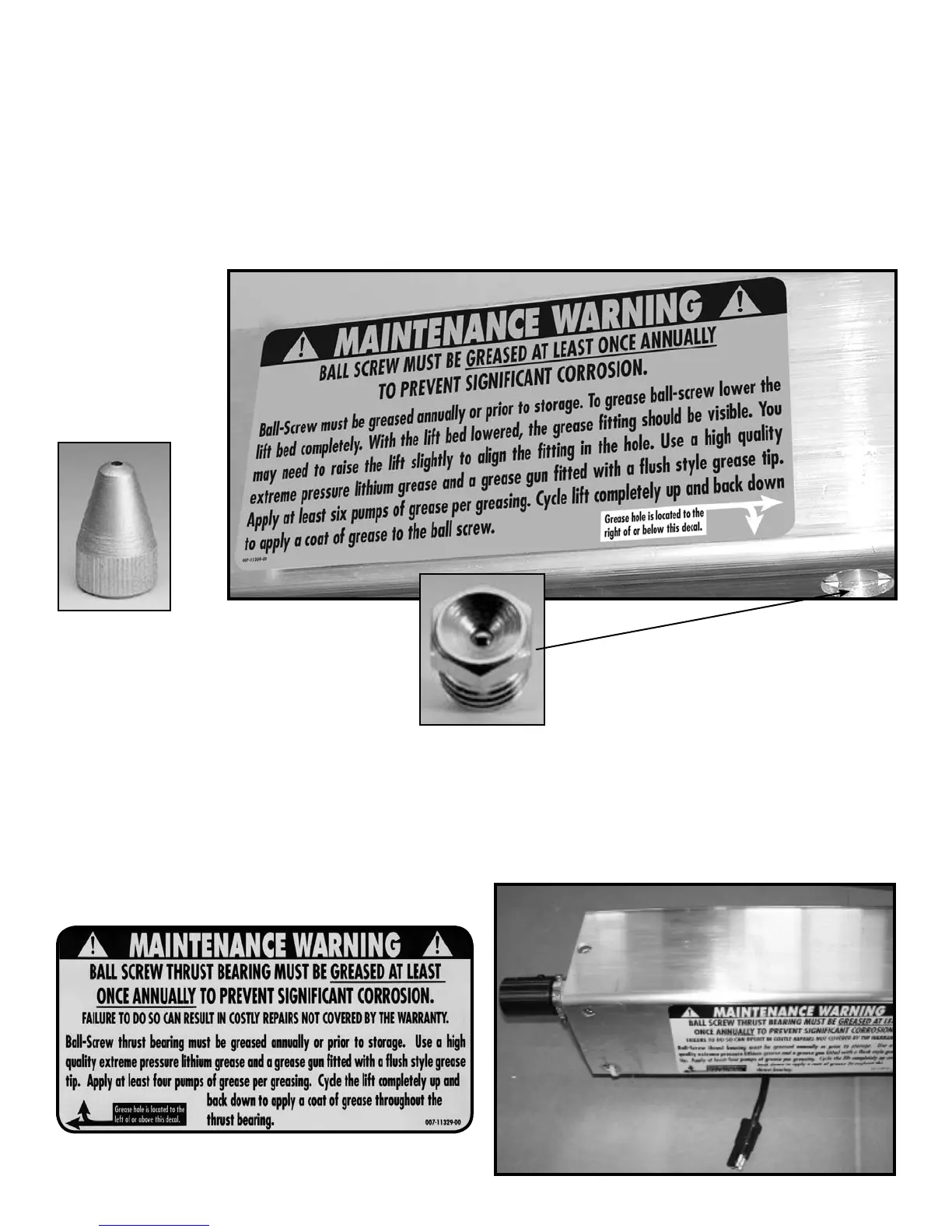

It is important to grease the ball-screw mechanism annually to prevent signicant corrosion. The ball-

screw must be greased immediately prior to winter storage. To grease the ball-screw, lower the lift bed

completely. With the bed lowered, the grease tting should be visible. It may be necessary to raise the

lift slightly to align the grease tting in the hole. Use a high quality extreme pressure lithium grease and

a grease gun tted with a ush style grease tip as shown in Fig. 73 below. A lithium grease that meets

these specications is AeroShell Gadus S2 V220 2. Apply at least six pumps of grease per greasing.

Cycle lift completely up and back down to apply a coat of grease to the ball-screw.

Flush Style Fitting

This tting allows mess-free greasing access to

the ball-screw mechanism.

Fig. 73

Flush-Style Grease Gun Tip

Use a ush style coupler grease tip like the

one included in your tool kit for your grease

gun. Similar adapters are available through

NAPA automotive parts stores.

(NAPA part number 715 1215)

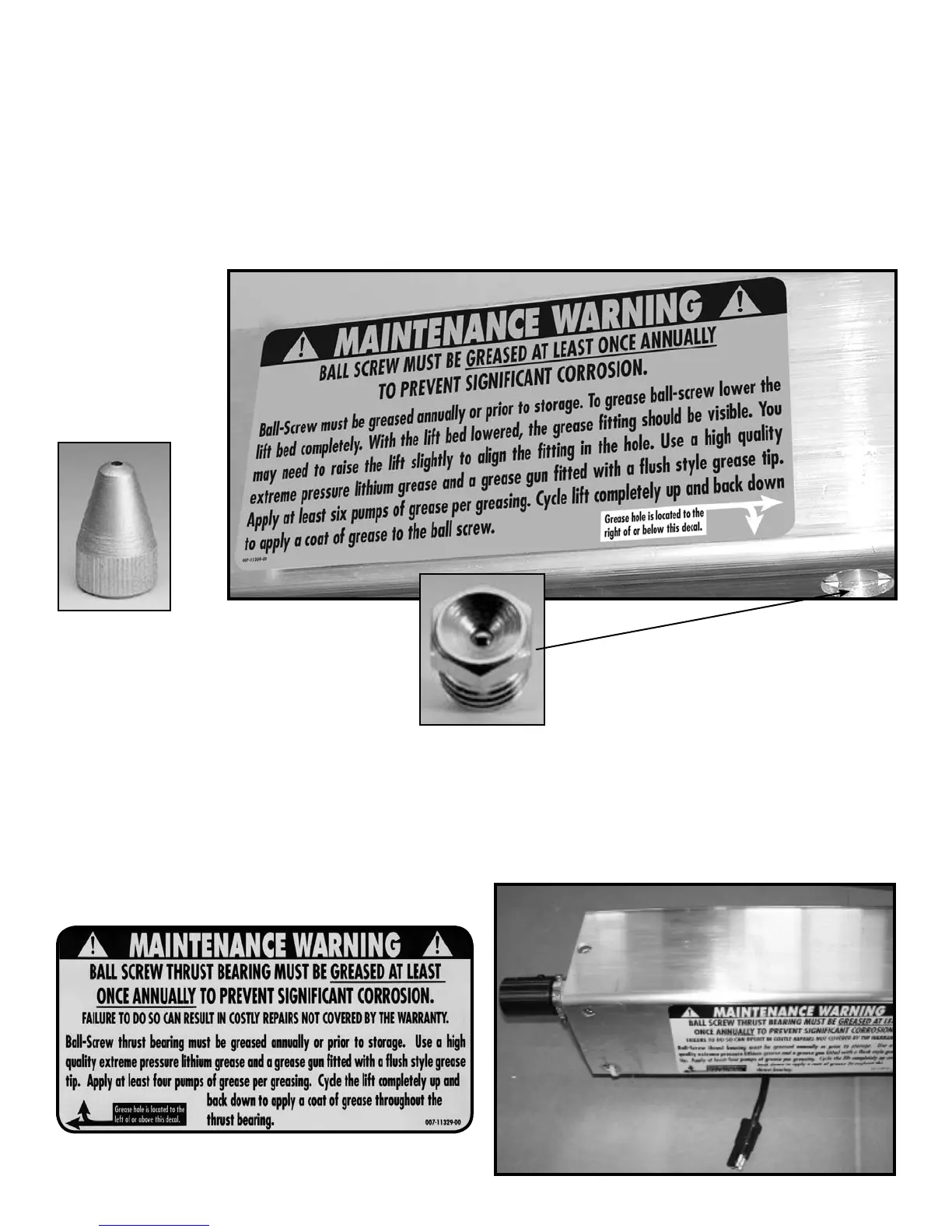

GREASING THE THRUST BEARING

It is important to grease the thrust bearing mechanism annually to prevent signicant corrosion. See maintenance

warning decal below and on your lift.

Loading...

Loading...