LR, LRV, LLR and LR-S USER INSTRUCTIONS ENGLISH 71569088 08-10

Page 19 of 48 flowserve.com

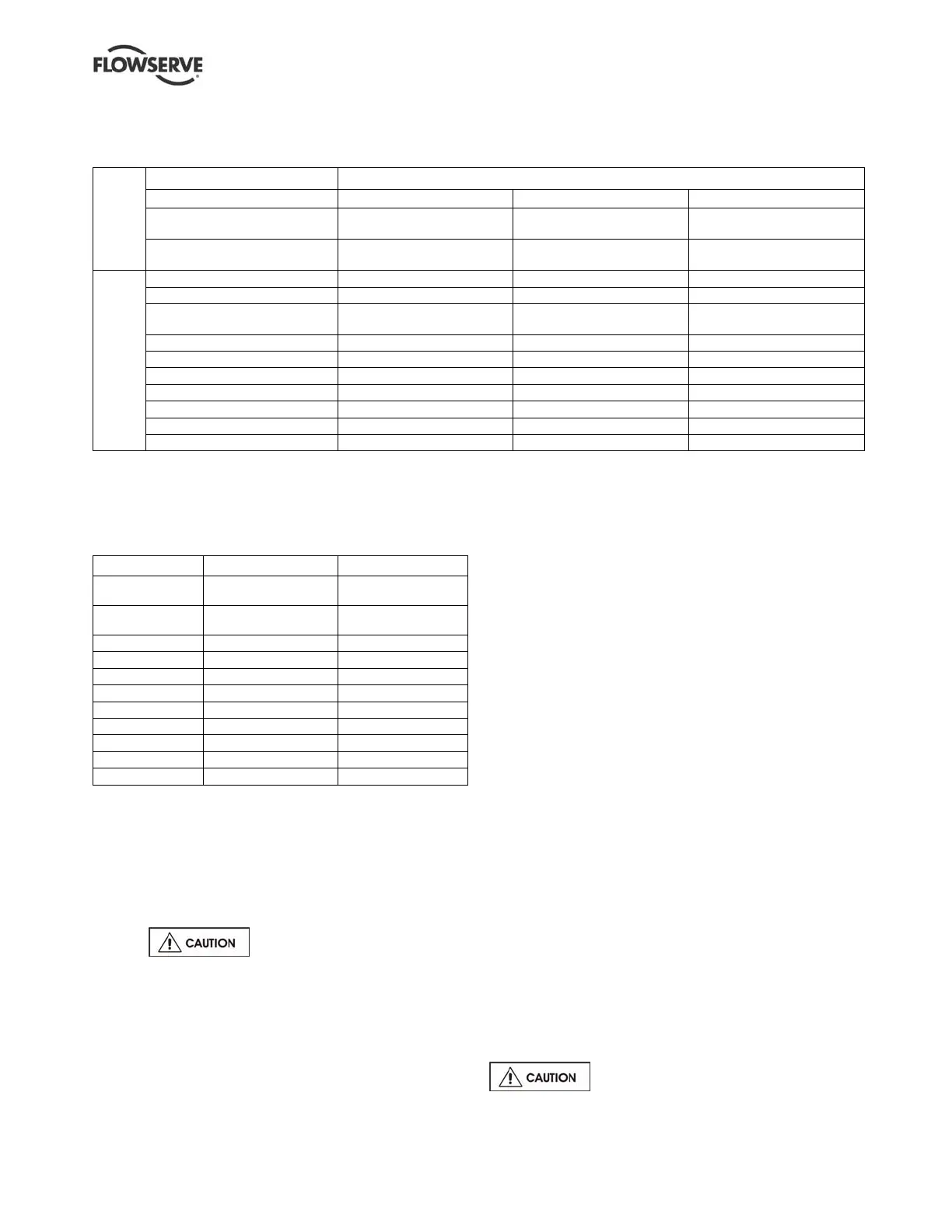

5.2 Pump lubricants

5.2.1 Recommended oil lubricants

Oil Splash / force feed / purge & pure** oil mist lubrication

Viscosity cSt @ 40 ºC

32 46 68

Oil temperature range *

-5 to 65 ºC

(23 to 149 ºF)

-5 to 78 ºC

(23 to 172 ºF)

-5 to 80 ºC

(23 to 176 ºF)

Centrifugal

pump lubrication

Designation to ISO 3448

and DIN51524 part 2

ISO VG 32

32 HLP

ISO VG 46

46 HLP

ISO VG 68

68 HLP

BP Castrol

†

Energol HLP-HM 32 Energol HLP-HM 46 Energol HLP-HM 68

ESSO

†

NUTO HP 32 NUTO HP 46 NUTO HP 68

ELF/Total

†

ELFOLNA DS 32

Azolla ZS 32

ELFOLNA DS 46

Azolla ZS 46

ELFOLNA DS 68

Azolla ZS 68

LSC (for oil mist) LSO 32 (Synthetic oil) LSO 46 (Synthetic oil) LSO 68 (Synthetic oil)

ExxonMobil

†

Mobil DTE 24 Mobil DTE 25 Mobil DTE 26

Q8

†

Q8 Haydn 32 Q8 Haydn 46 Q8 Haydn 68

Shell

†

Shell Tellus 32 Shell Tellus 46 Shell Tellus 68

Chevron Texaco

†

Rando HD 32 Rando HD 46 Rando HD 68

Wintershall (BASF Group)

†

Wiolan HS32 Wiolan HS46 Wiolan HS68

Oil companies and

lubricants

Fuchs

†

Renolin CL 32 Renolin CL 46 Renolin CL 68

* Note that it normally takes 2 hours for bearing temperature to stabilize and the final temperature will depend on the ambient, r/min, pumpage

temperature and pump size. Also some oils have a very low pour point and good viscosity index which extend the minimum temperature capability

of the oil. Always check the grade capability where the ambient is less than -5 ºC (23 ºF).

** If preheated pure oil mist lubrication LCS LSO 68 or LSO 100 synthetic oils are permitted.

†

Use LSC for oil mist. Oil parameters provide flash point >166 ºC (331 ºF), density >0.87 @ 15 ºC (59 ºF), pour point of -10 ºC (14 ºF) or lower.

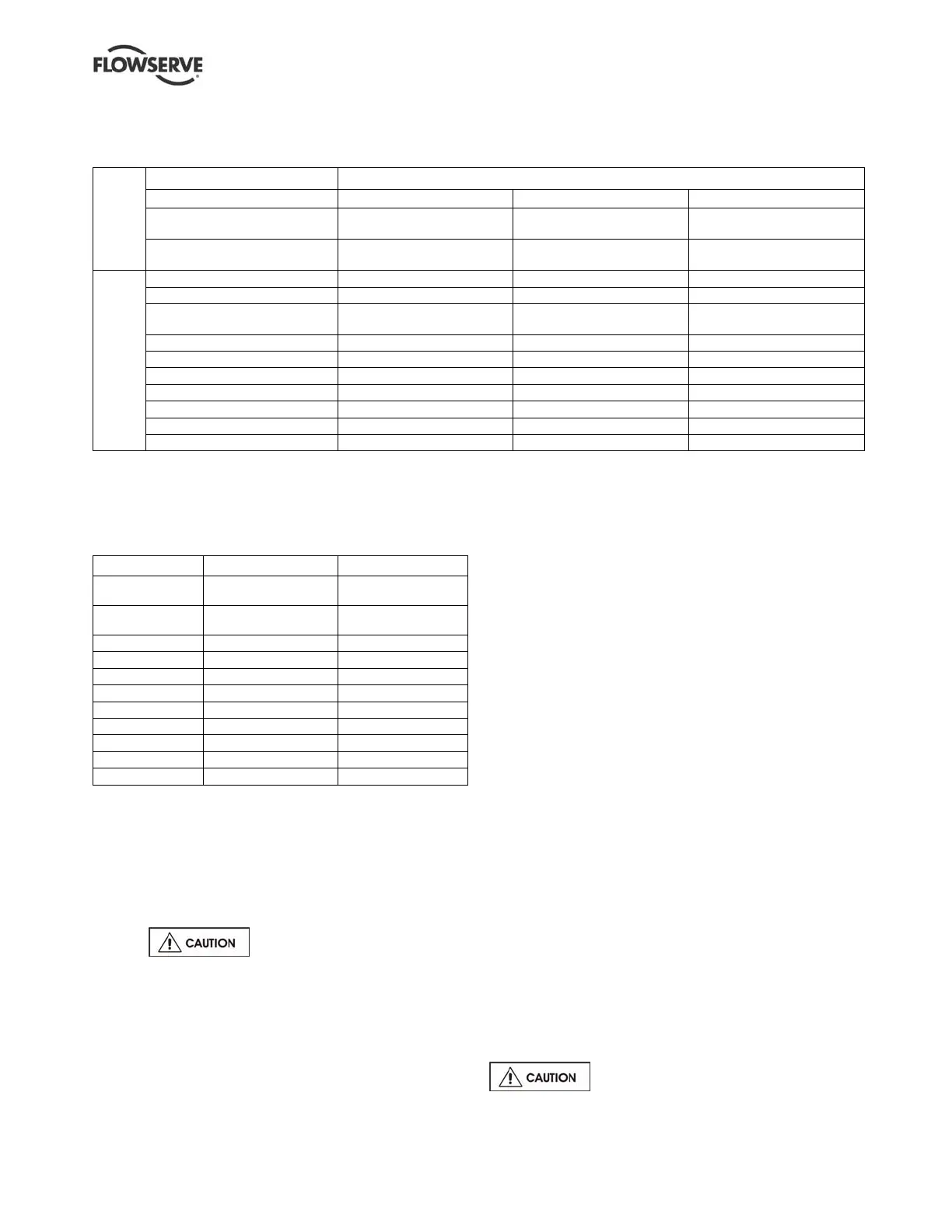

5.2.2 Recommended grease lubricants

Grease NLGI 2 * NLGI 3

Temp. range

-20 to +100 ºC

(-4 to +212 ºF)

-20 to +100 ºC

(-4 to +212 ºF)

Designation

acc. to DIN

KP2K-25 KP3K-20

BP Energrease LS-EP2 Energrease LS-EP3

Elf Multis EP2 Multis EP3

Fuchs RENOLIT EP2 RENOLIT EP3

ESSO Beacon EP2 Beacon EP3

Mobil Mobilux EP2 Mobilux EP3 **

Q8 Rembrandt EP2 Rembrandt EP3

Shell Alvania EP2 Alvania EP2

Texaco Multifak EP2 Multifak EP3

SKF LGEP 2

* NLGI 2 is an alternative grease and is not to be mixed with other

grades.

** Standard pre-packed grease for fitted antifriction bearings.

†

Food type grease regreasing interval is 1200 hours. (Grease not

to be mixed with non-food grade.)

5.2.3 Recommended fill quantities

Refer to section 3.4.2, Pump and impeller data.

5.2.4 Lubrication schedule

5.2.4.1 Oil lubricated bearings

Normal oil change intervals are 4 000 operating hours

or at least every 6 months. For pumps on hot service

or in severely damp or corrosive atmosphere, the oil

will require changing more frequently. Lubricant and

bearing temperature analysis can be useful in

optimizing lubricant change intervals.

The lubricating oil should be a high quality mineral oil

having foam inhibitors. Synthetic oils may also be

used if checks show that the rubber oil seals will not

be adversely affected.

The bearing temperature may be allowed to rise to

50 C (90 F) above ambient, but should not exceed

82 C (180 F). A continuously rising temperature or

an abrupt rise, indicate a fault.

5.2.4.2 Grease lubricated bearings

When grease nipples are fitted, one charge between

grease changes is advisable for most operating

conditions, ie 2 000 hours interval.

Normal intervals between grease changes are 4 000

hours or at least every 6 months.

The characteristics of the installation and severity of

service will determine the frequency of lubrication.

Lubricant and bearing temperature analysis can be

useful in optimising lubricant change intervals.

The bearing temperature may be allowed to rise to

55 C (99 F) above ambient but should not exceed

95 C (203 F). For most operating conditions a quality

grease having a lithium soap base and NLGI

consistency of No 2 or No 3 is recommended. The

drop point should exceed 175 C (350 F).

Never mix greases containing different

bases, thickeners or additives.

Loading...

Loading...