Logix

®

420 Digital Positioner FCD LGENIM0106-07-AQ – 10/15

4

Between actuator and valve there are moving parts. To avoid injury

FLOWSERVE provides pinch-point-protection in the form of cover

plates, especially where side-mounted positioners are fitted. If these

plates are removed for inspection, service or repair special attention is

required. After completing work the cover plates must be refitted.

Logix 420 positioner repair is limited to the replacement of sub-assem-

blies and circuit boards with FLOWSERVE-manufactured replacements

as outlined in this manual.

1 CAUTION: Before products are returned to FLOWSERVE for repair

or service, FLOWSERVE must be provided with a certificate

which confirms that the product has been decontaminated and is

clean. FLOWSERVE will not accept deliveries if a certificate has

not been provided (a form can be obtained from FLOWSERVE).

Apart from the operating instructions and the obligatory accident

prevention directives valid in the country of use, all recognized regula-

tions for safety and good engineering practices must be followed.

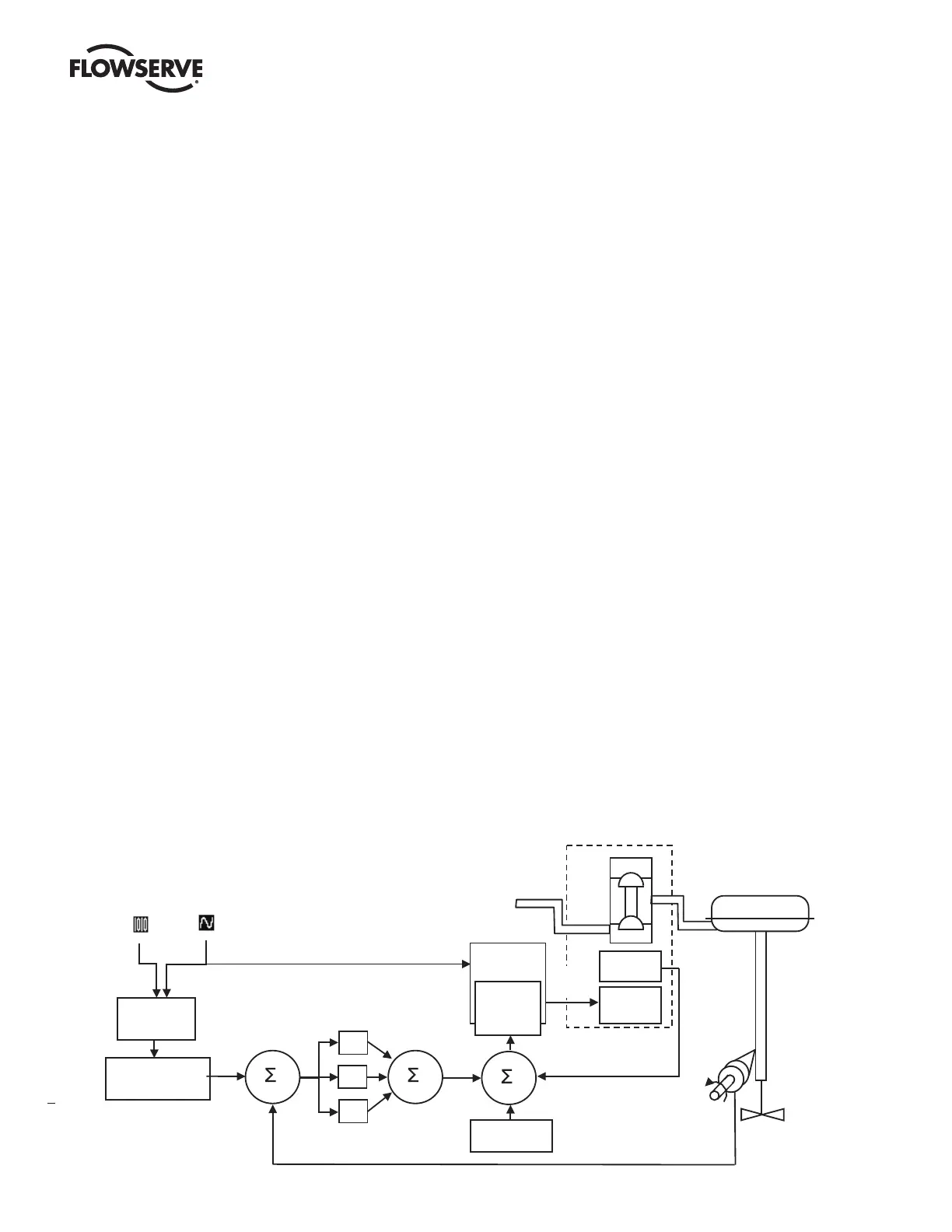

PRINCIPLES OF OPERATION

1.8 Basic Operation

The Logix 420 digital positioner is a two-wire 4-20 mA input digital

valve positioner which uses the HART protocol to allow two-way remote

communications. The positioner is completely powered by the 4-20 mA

input signal. Start-up current must be at least 3.8 mA. The positioner

is configurable through the local user interface, hand-held or DTM. The

Logix 420 positioner can control single-acting pneumatic actuators with

linear or rotary mountings.

The Logix 420 digital positioner is an electronic and pneumatic closed-

loop feedback instrument. Figure 1 shows a schematic of a Logix 420

positioner installed on a single-acting linear actuator for air-to-open

action.

1.9 HART

The Logix 420 receives power from the two-wire, 4-20 mA input signal.

However, since this positioner utilizes HART communications, two

sources can be used for the command signal: Analog and Digital. In

Analog source, the 4-20 mA signal is used for the command source.

In Digital source, the level of the input 4-20 mA signal is ignored (used

only for power) and a digital signal, sent via the HART communication

protocol, is used as the command source. The command source can be

accessed with ValveSight software, the HART 375 communicator,

or other host software. See section 11 HART COMMUNICATION

HART COMMUNICATION for more information.

1.10 Position Definition

Whether in Analog or Digital Source, The position at 0% is always

defined as the valve in a closed position and 100% is always defined as

the valve in an open position. In Analog Source, the 4-20 mA signal is

converted to a position (in percent). During loop calibration, the signals

corresponding to 0% and 100% are defined.

1.11 Command Input and Final Command

The Command Input signal (in percent) passes through a characteriza-

tion/limits modifier block. This function is done in software, which

allows for in-the-field customer adjustment. The characterization

block can apply no adjustment (Linear), one of several pre-defined

Figure 1: Principles of Operation of Logix 420

Valve

Pilot Relay

Circuit

Loop

Spool

Control

Command

Input

Soft Limits,

Command

Comman

d Input

(4-20 mA)

Percentage

Figure 1: Principle of Operation of Logix 420

Loading...

Loading...