Logix

®

420 Digital Positioner FCD LGENIM0106-07-AQ – 10/15

6

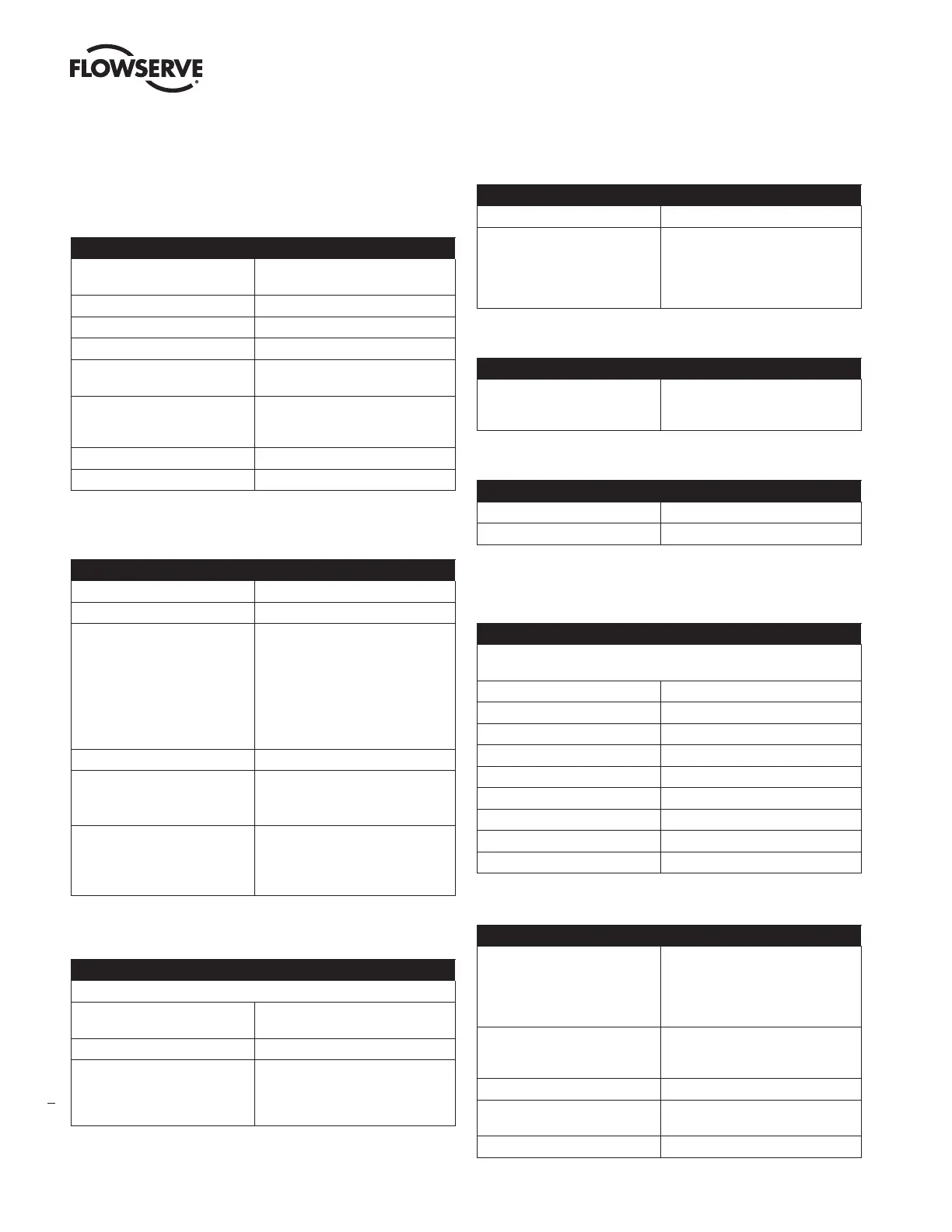

2 SPECIFICATIONS

2.1 Input Signal

Table 1: Input Signal

Power Supply

Two-wire, 4-20 mA

10.0 VDC terminal voltage

Input Signal Range 4 - 20 mA (HART)

Compliance Voltage 10.0 VDC @ 20 mA

Effective Resistance 500 Ω @ 20 mA Typical

Minimum Required

Operating Current

3.8 mA

Signal Interrupt Without Restart

Time (after powering positioner

for at least one minute)

80 ms

Maximum Shut-down Current 3.6 mA

Communications HART protocol

2.2 Air Supply

Table 2: Air Supply

Minimum Input Pressure 1.5 Bar (22 PSI)

Maximum Input Pressure Single Acting Relay – 6 Bar (87 PSI)

Air Supply Quality The air supply must be free from

moisture, oil and dust by conforming

to the ISA 7.0.01 standard. (A dew

point at least 18 degrees Fahrenheit

below ambient temperature, particle

size below five microns—one micron

recommended—and oil content not to

exceed one part per million).

Operating Humidity 0 - 100% non-condensing

Acceptable Supply Gasses Air, sweet natural gas, nitrogen and

CO2 are acceptable supply gasses.

Sour natural gas is not acceptable.

Air Consumption

0.069 Nm³/h @ 1.5 bar

(0.041 SCFM @ 22 PSI)

0.082 Nm³/h @ 4.1 bar

(0.050 SCFM @ 60 PSI)

2.3 Physical Specifications

Table 3: Physical Specifications

For dimensions, see section 15 POSITIONER DIMENSIONS.

Housing Material Cast, powder-painted aluminum

EN AC-AlSi12(Fe)

Soft Goods Fluorosilicone

Weight of Base Positioner

Without Accessories

With LCD and Glass Cover

2.70 kg (5.95 lb)

With Solid Cover

3.11 kg (6.85 lb)

2.4 Pneumatic Output

Table 4: Pneumatic Output

Output Pressure Range 0 to 100% of air supply pressure.

Output Air Capacity

Single Acting Relay –

9.06 Nm³/h @ 1.5 bar

(5.33 SCFM @ 22 PSI)

20.8 Nm³/h @ 4.1 bar

(12.2 SCFM @ 60 PSI)

2.5 Stroke Output

Table 5: Stroke Output

Feedback shaft Rotation

Min 15°, Max 90°

45° recommended for linear

applications.

2.6 Temperature

Table 6: Temperature

Operating Temperature Range* -52 to 85°C (-61.6 to 185°F)

Transport and Storage Range -52 to 85°C (-61.6 to 185°F)

*Reduced performance at low temperatures.

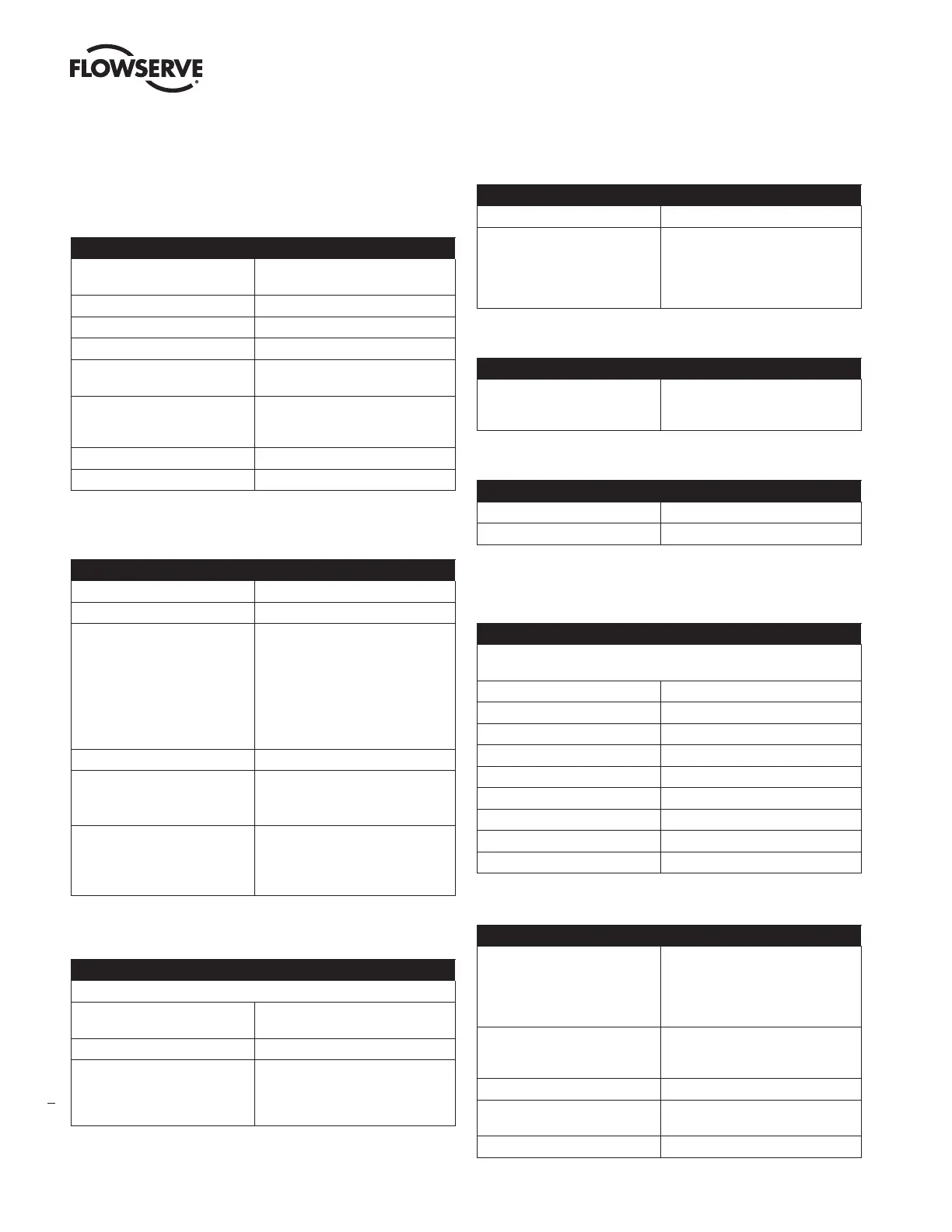

2.7 Positioner Performance Characteristics

Table 7: Performance Characteristics

Better than or equal to the following values on a 25 square inch Mark I

actuator per standard ISA 75.13.

Resolution ≤ 0.25%

Linearity +/-1.25%

Repeatability ≤ 0.25%

Hysteresis ≤ 1.0%

Deadband ≤ 0.3%

Sensitivity ≤ 0.25%

Stability ≤ 0.4%

Long term drift ≤ 0.5%

Supply Pressure Effect ≤ 0.2%

2.8 ValveSight DTM Software Specifications

Table 8: Pneumatic Output

Computer Minimum Pentium processor running

Windows 95, 98, NT, 2000, XP, 32 MB

total memory (64 MB recommended),

30 MB available hard disk space,

CD-ROM drive

Ports 1 minimum available with 8 maximum

possible. (Can also communicate via

serial, PCMCIA and USB connections)

HART Modem RS-232, PCMCIA card, or USB

HART Filter May be required in conjunction with

some DCS hardware.

HART MUX MTL 4840/ELCON 2700

Loading...

Loading...