USER INSTRUCTIONS MARK 3 High Silicon Iron ENGLISH 71569249 09-04

®

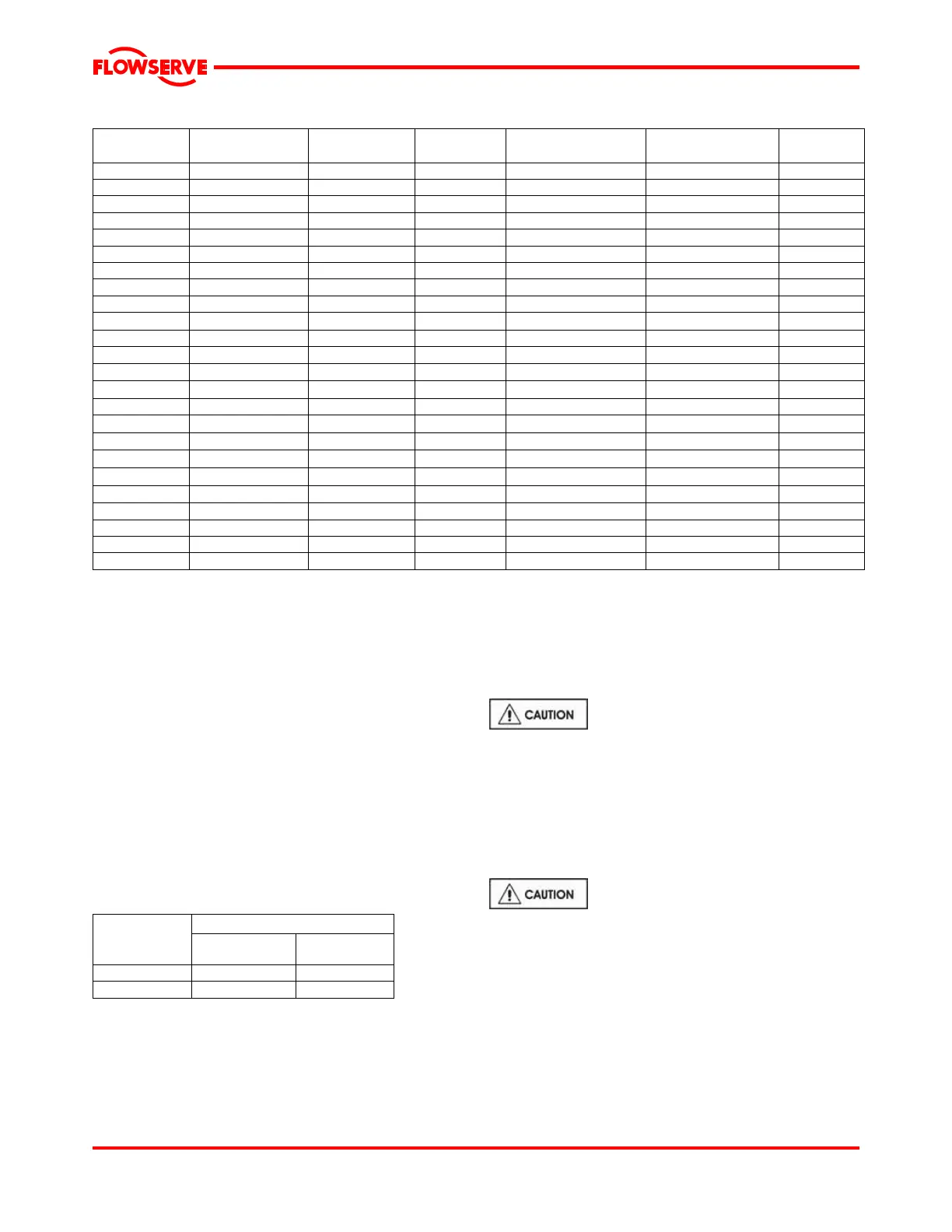

Figure 3-2: Alloy cross-reference chart

Flowserve

Material Code

Designation

Durco Legacy

Codes

ACI

Designation

Equivalent Wrought

Designation

ASTM

Specifications

Material

Group No.

E3020 Ductile iron DCI None None A395, Gr. 60-40-18 1.0

E3033 High chrome iron CR28 None None A532 class 3 Cr

E4027 High chrome iron CR29 None None None Cr

E4028 High chrome iron CR35 None None None Cr

C3009 Carbon steel DS None Carbon steel A216 Gr. WCB 1.1

C3062 Durco CF8 D2 CF8 304 A744, Gr. CF8 2.1

C3069 Durco CF3 D2L CF3 304L A744, Gr. CF3 2.1

C3063 Durco CF8M D4 CF8M 316 A744, Gr. CF8M 2.2

C3067 Durco CF3M D4L CF3M 316L A744, Gr. CF3M 2.2

C3107 Durcomet 100 CD4M CD4MCuN

Ferralium®

A995, Gr. CD4MCuN 2.8

C4028 Durimet 20 D20 CN7M Alloy 20 A744, Gr. CN7M 3.17

C4029 Durcomet 5 DV None None None 2.2

K3005 Durco CY40 DINC CY40

Inconel® 600

A494, Gr. CY40 3.5

K3007 Durco M35 DMM M351

Monel® 400

A494, Gr. M35-1 3.4

K3008 Nickel DNI CZ100 Nickel 200 A494, Gr. CZ100 3.2

K4007 Chlorimet 2 DC2 N7M

Hastelloy® B

A494, Gr. N7M 3.7

K4008 Chlorimet 3 DC3 CW6M

Hastelloy® C

A494, Gr. CW6M 3.8

E3041

Duriron®

D None None A518, Gr. 1 No load

E3042

Durichlor 51®

D51 None None A518, Gr. 2 No load

E4035

Superchlor®

SD51 None None A518, Gr. 2 No load

D4036 Durco DC8 DC8 None None None -

H3004 Titanium Ti None Titanium B367, Gr. C3 Ti

H3005 Titanium-Pd TiP None Titanium-Pd B367, Gr. C8A Ti

H3007 Zirconium Zr None Zirconium B752, Gr. 702C Ti

® Duriron, Durichlor 51 and Superchlor are registered trademarks of Flowserve Corporation.

® Ferralium is a registered trademark of Langley Alloys.

® Hastelloy is a registered trademark of Haynes International, Inc.

® Inconel and Monel are registered trademarks of International Nickel Co. Inc.

3.4.2 Pressure-temperature ratings

The maximum allowable discharge pressure is

6.9 bar (100 psi) from -29 to 176˚C (-20 to 350˚F).

3.4.3 Suction pressure limits

Suction pressure is limited only by the pressure

temperature ratings of the pump. Specific gravity is

limited to 2.0.

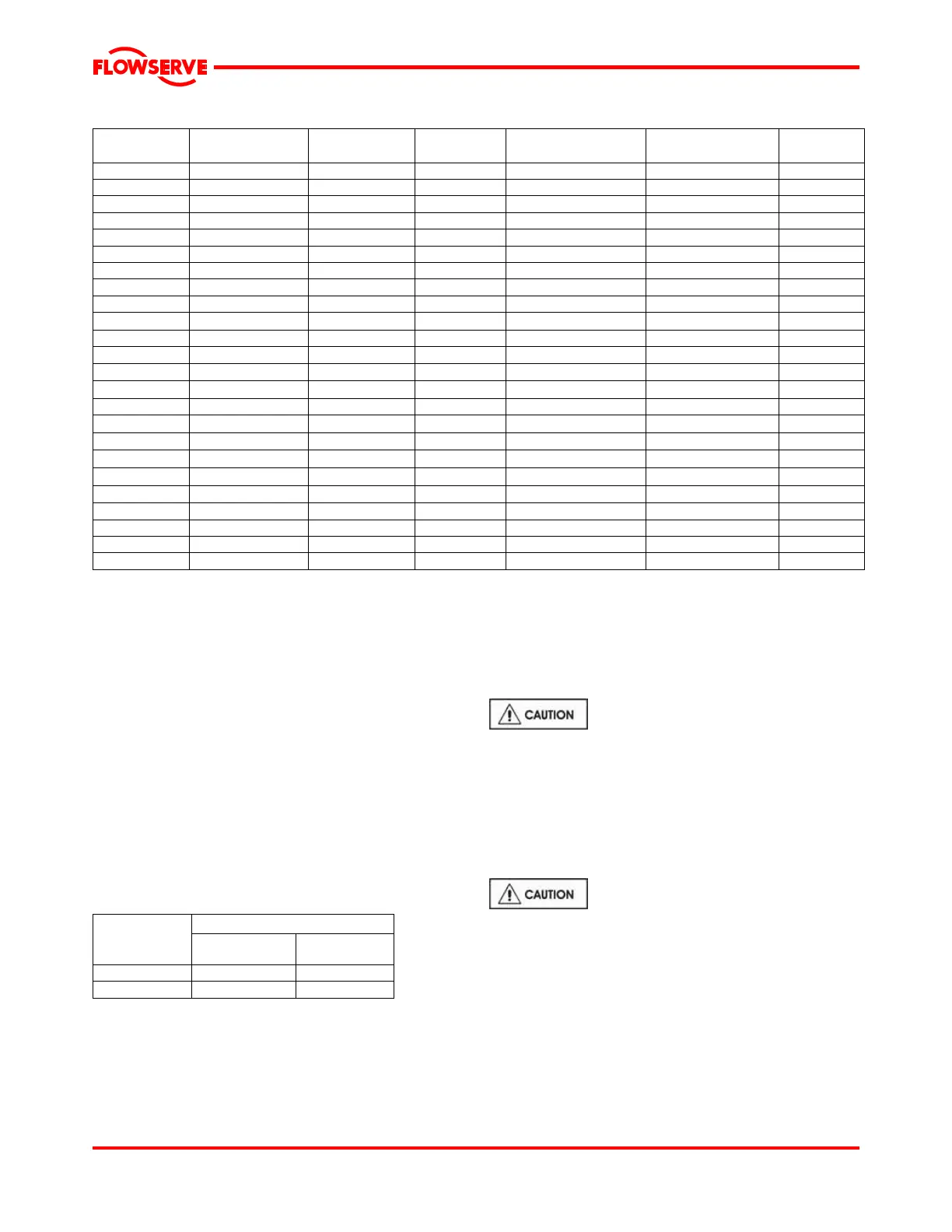

3.4.4 Minimum continuous flow

The minimum continuous flow (MCF) is based on a

percentage of the best efficiency point (BEP). Figure

3-3 identifies the MCF.

Figure 3-3: Minimum continuous flow

MCF % of BEP

Pump size

1750/1450

r/min

1180/960

r/min

2K4x3H-13 20% 10%

All other sizes 10% 10%

4 INSTALLATION

High Silicon Iron components

If any of the components of the pump

have been made of High Silicon Iron, the following

precautionary measures should be followed:

• Use hand wrenches rather than impact wrenches

• This equipment should not be subjected to

sudden changes in temperature or pressure

• Avoid striking this equipment with any sharp blows

High Silicon Iron components

Avoid any repair or fabrication welds

on High Silicon Iron components.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance, and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Refer to the general arrangement drawing for the

pump set.

Page 12 of 48

Loading...

Loading...