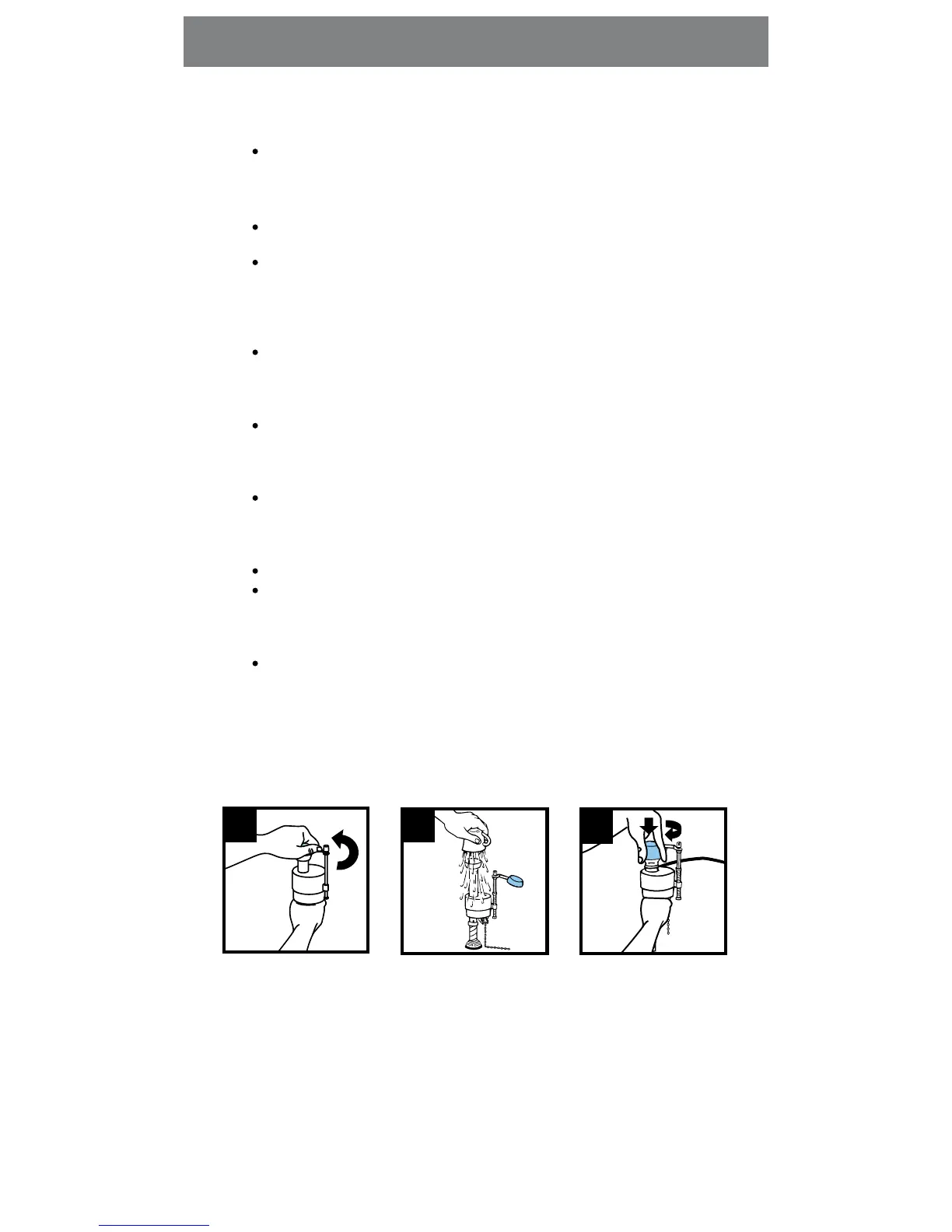

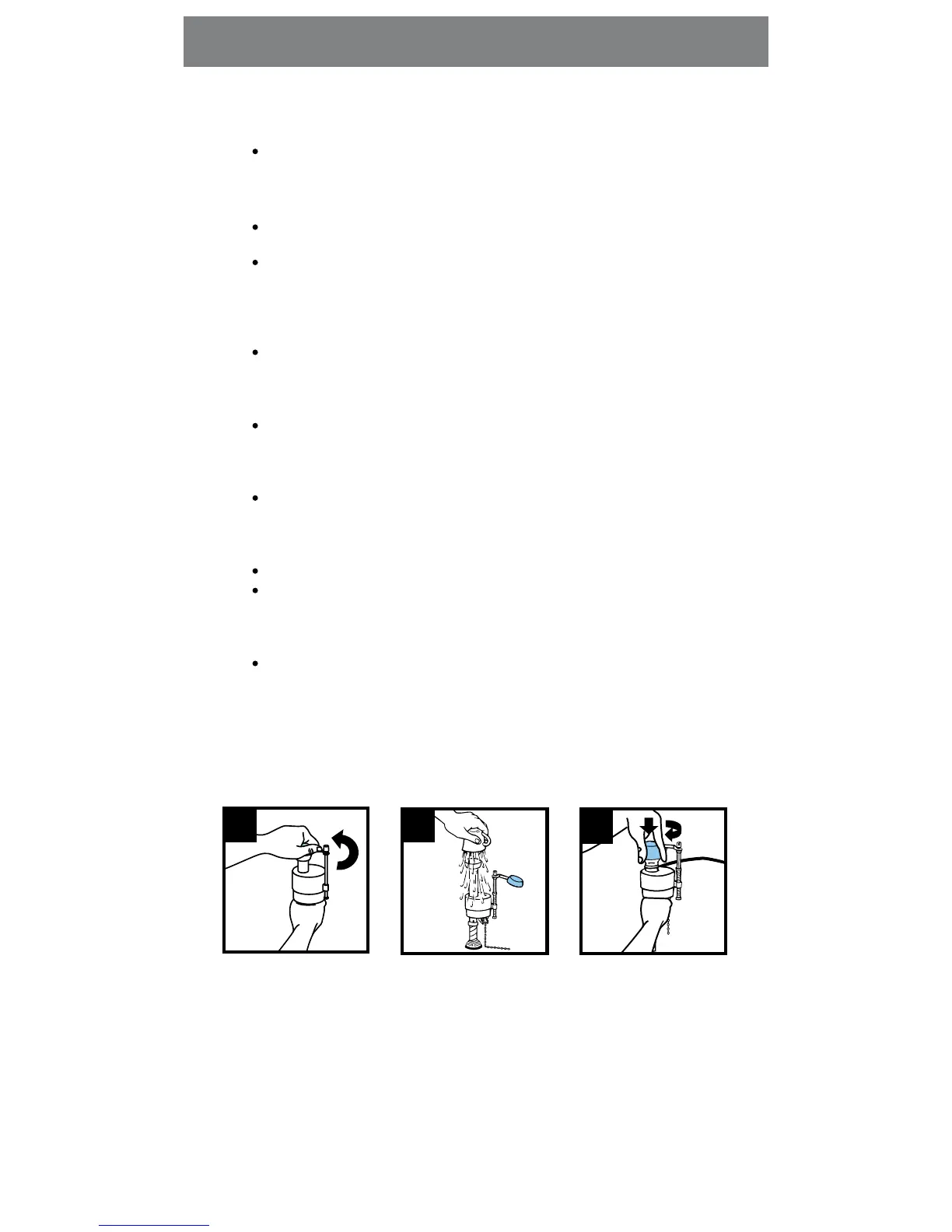

1 2 3

Remove cap assembly. Flush out valve. Hold

cup over valve. Turn on

water.

FLUSHING OUT DEBRIS

FILL VALVE WILL NOT TURN OFF

WATER LEVEL IN BOWL IS TOO LOW

Move roller clamp to higher number.

There may be debris at seal. Sand and rust move through water pipes.

Always clear debris from water lines. See “Flushing Out the Debris” below.

The seal inside the valve top may be damaged-replace with a genuine

Fluidmaster 242 seal.

FULL FLUSH WILL NOT ADEQUATELY REMOVE WASTE

Lower grey oat to allow more water to be ushed.

HALF FLUSH WILL NOT ADEQUATELY REMOVE WASTE

Lower blue oat to allow more water to be ushed.

SEAL LEAKING

Should dual ush valve leak, unclip valve from base, and re-align seal.

FULL FLUSH CLOSES IMMEDIATELY AFTER LEVER IS RELEASED

Top of rell mount should be set 2” above top of overow tube.

Raise rell mount higher. (see step 2.4)

OVERFLOW TUBE STICKS OPEN ON FULL & HALF FLUSH

Remove cable mount from Dual Flush assembly. Check lever cable for kinks.

Straighten by hand. If cable still sticks, replace cable.

Go to our website at www.uidmaster.com for more solutions to toilet problems.

Replace cap assembly.

14

Troubleshooting

Loading...

Loading...