Maintenance

Introduction

3

3-3

XWWarning

To avoid electric shock or personal injury:

• Do not perform any servicing other than operator

maintenance unless you are qualified to do so. These

service instructions are for used by qualified personnel

only.

• Do not allow water to get inside case.

• Remove any input signals prior to removing test leads and

opening case.

• When servicing the meter, use only specified replacement

parts.

• Make sure the battery door is closed and latched before you

operate the meter.

• To prevent arc blast and resulting injury, install only

specified replacement fuses with the speed, amperage,

interrupt rating and voltage rating listed in Fuse

Replacement section.

3-1. Introduction

This chapter presents instructions for disassembly, performance tests, calibration

adjustment, and troubleshooting. The performance tests may be used as an acceptance

test when the instrument is first received, and can be used later as a preventive

maintenance tool.

A l-year calibration cycle is recommended to maintain the instrument’s specifications. In

addition, the seals should be replaced during servicing to maintain the environmental

specifications stated in that manual. A seal kit is available from the factory. The seal kit

(Model 8025A-740 1, part number 738112) contains a complete set of seals and four

replacement screws and washers for the bottom case.

The test equipment required for the performance tests and calibration adjustments is

listed in Table 3-1. Test equipment with equivalent specifications may be used if the

recommended models are unavailable.

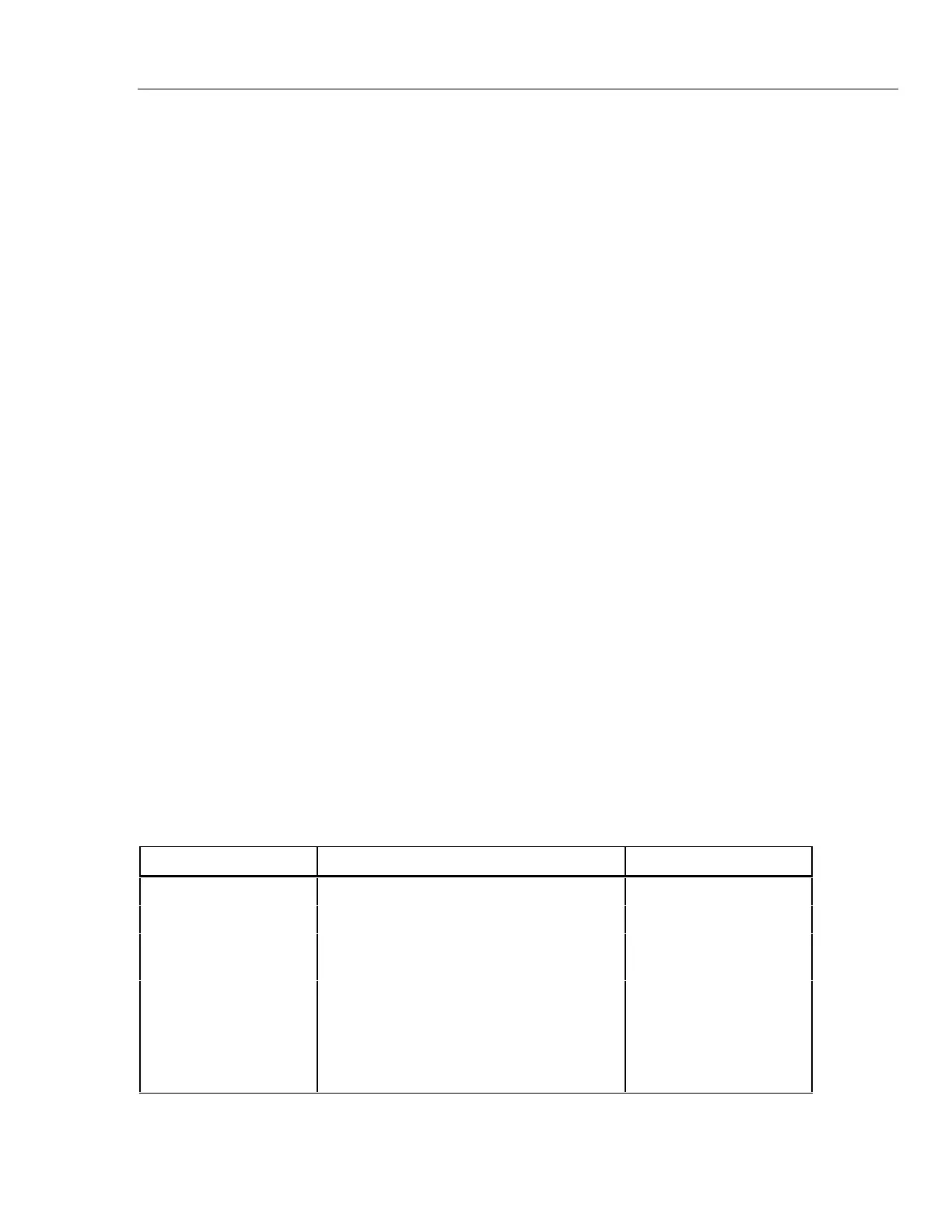

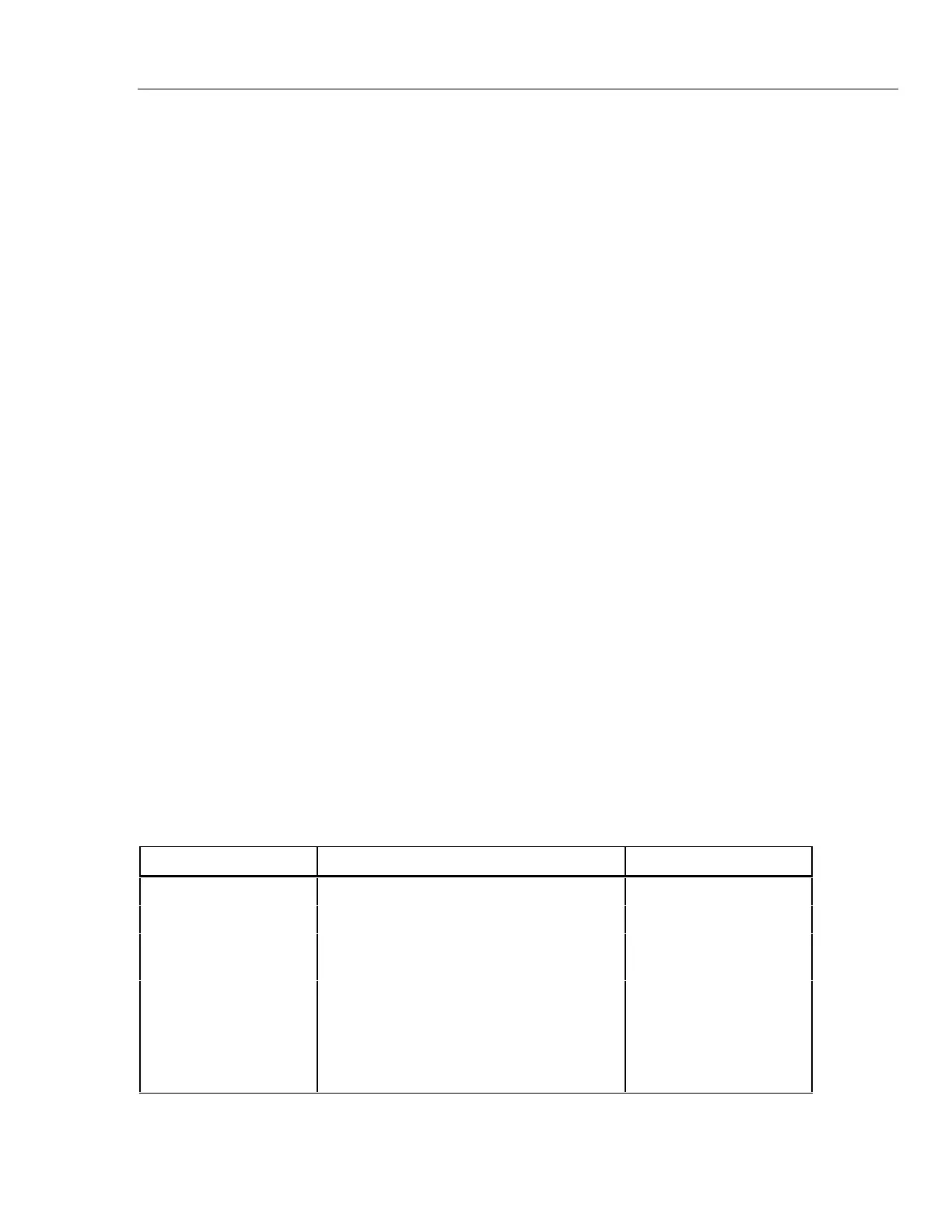

Table 3-1. Recommended Test Equipment

Instrument Type Required Characteristics Recommended Model

Voltage Range: 0-1000 V ac, ±.05%

Frequency Range: 40 - 10,000 Hz, ±1%

DMM Calibrator Voltage Range: 0-1000 V dc

Accuracy: ±.05%

Fluke Model 5500A

Current Range: 2 mA - 5 A

Accuracy: ±.2%

Values: 100 ohm, 1 kilohm, 10 kilohm, 100

kilohm, 1 megohm, 10 megohm

Accuracy±.06%

Loading...

Loading...